As the time counts down until we hit the water, it’s time to start working on the sails. It’s a massive undertaking even for someone who has an above average ability for sewing and stitchery. But despite my public school 7th grade Home Ec course, this is far and beyond the first pillowcase my grandmother taught me to sew on her Singer sewing machine. Even tailoring classes in college can’t compare nor the dozens of garments that I sewed including prom dresses, camp shorts, and outrageous Halloween costumes. These sails are HUGE! With that in mind, I’m ready to take on this textile endeavor.

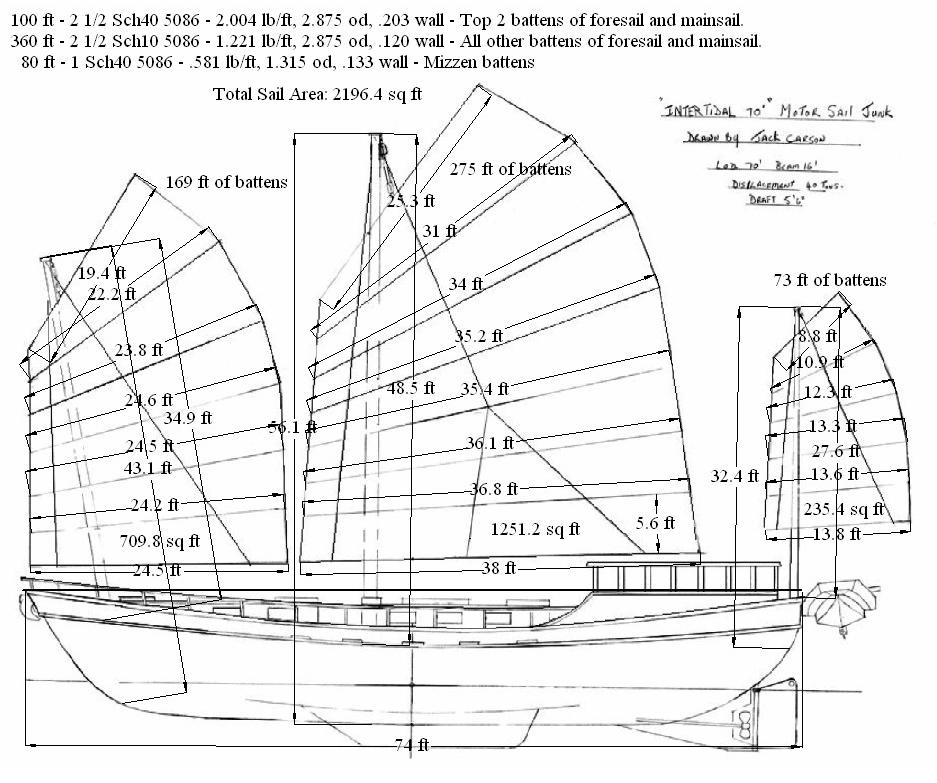

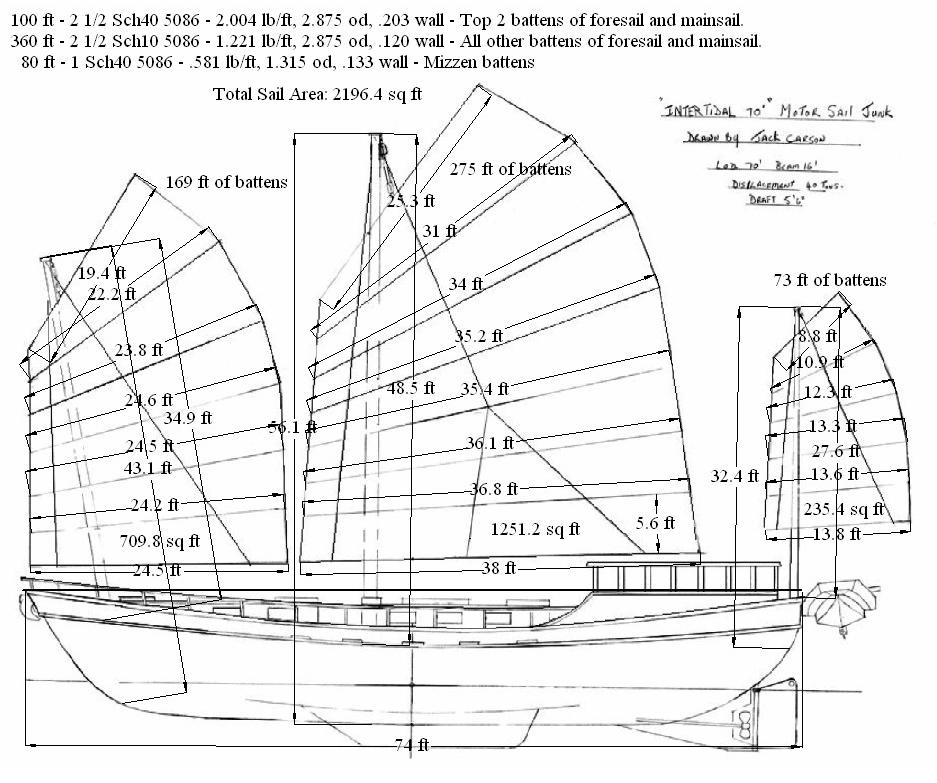

When the plans for the boat were drawn up, a drawing of the sales was also supplied. While it gives us a basic idea of what we’re trying to achieve, it is in no way what could be considered a “sail plan” or “sail design”. The original drawing from the boat designer shows a few measurements on an outline that includes batten placements. By scanning this into cad and plugging in the measurements, we arrived at what is the general sail design. Fortunately it meets the ratios for what is called a “low aspect sail” in the world of Chinese Lug Sails but other than that… we’re on our own.

With this in mind, we made some calculations and arrived at some approximate measurements in order to calculate the yardage of sailcloth needed.

Mainsail: 1,251 sq feet or 139 sq. yards

Foresail: 710 sq feet or 79 sq. yards

Mizzen: 235 sq feet or 26 sq. yards

The color is Tanbark (though you might call it red)

Points to consider:

- We’ve always wanted red sails. The actual term for that color is Tan Bark.

- Options are to go with a canvas like Sunbrella or a more common sail fabric, Dacron.

- Both are available in variable weights but the Dacron will stretch less than the canvas (and it’s less expensive)

- No raveling on the edges makes the actual layout and sewing much easier.

- The larger sail will require a heavier canvas than the smaller sail

Now comes the hard part. How heavy must the fabric be and where do you get the stuff?

What’s interesting is that there are not very many junk rigs in excess of 50′. Most of the websites and catalogues for sailcloth speak in boat lengths up to 50′. The next largest junk rig we have to compare is the 60′ Magic Pearl which is being constructed by Robin & Kim. For their mainsail they chose a 10 ounce dacron. But we’re still 25% bigger.. so what do we do?

All Dacron sails begin at the same point — Dupont. The fibers are then woven, treated and heated and given catchy sailing names by less than a handful of Sailcloth makers in the world. I checked the retail outlets… but 8.5 ounces is the heaviest fabric I can find.

So I went Wholesale! I first contacted Bainbridge — an American company who offered a Tanbark sailcloth but only up to 8.5 ounces. FYI weights are per square yard… and a square yard for this weight measurement is actually about 32″ x 36″.

Bainbridge is a wholesaler so I knew that I might have a few problems communicating with a salesman, but what the heck. As I feared, Mario was not much help and really knew very little about the product or it’s possibilities. He told me to call a sailmaker as they would have to provide the prices and any other information. But I’m the sailmaker!!!!! I asked if it was true that their Tanbark product was only available up to 8.5 ounces. Yeah…said Mario… and furthermore.. no special orders! Mario was evidently in a hurry to grab a slice and head for the Jersey shore!

So I moved to the next on my list, Challenge Sailmakers. I could never find a phone number… take note! So I moved on to the next one…

Contender Sailcloth. A European company, they have an office (sales) in the US and I had a great talk with Tom at 508-674-7700. Their product is called Fibercon AP and it’s available in a huge amount of weights all the way up to 15 ounces! Furthermore, we can order directly from them AND they’ll even send us a sample! Woohoo… customer service! While Tom was very informed on his product he still couldn’t confirm what weights we’d actually need although I do have it narrowed down.

Thoughts:

Main: 12.5 or 15 ounce ($27 or $29/yard

Fores’l: 9 ounce ($18/yard)

Mizzen: 7 or 8 ounce ($17)

All together that’s $6-$7000. (Don’t go all bean counter on me. it’s JUST an estimate)

They have the lighter weights in stock.. but the heavier one will likely need to be ordered… no problem… we have a few years time.

Next assignment is to see if I can’t find somebody out there who has experience in sales for boats over 70′ in length to try and narrow down the weights. Tom suggested I find David Bierig in Pennsylvania. He’s a Tall Ship sailmaker. Who knows… in 50 years of sailmaking, maybe he’s come across a junk rig. But first.. we have to find a phone number.

When it comes to boating, as with most things in life, there is no substitute for experience. This time of year, as boaters all across the country are returning to the water, many are venturing out on boats for the very first time. Remember that for most of the places boating and sailing requires a license, before you continue reading make sure to get familiar with this boating test exam.

IF YOU’RE ONE OF THESE ROOKIE BOATERS, HERE ARE A FEW TIPS TO HELP YOU IN YOUR FIRST BOATING SEASON.

- Check the weather before you hit the water. If you already checked it, check again before you head out. Weather changes, and unexpected storms can sneak up on you. If you’re new to boating, that’s no time to be caught by a surprise squall.

- Get on and off the boat ramp quickly so other boaters aren’t giving you the evil eye. Load your boat ahead of time—not on the ramp. Find an empty parking lot and practice steering with your trailer so you’ll have experience come launch day.

- Dress in layers. It might be warm on land, but you don’t want to get cold if the breeze kicks up on the water. Be prepared for changes in conditions.

- Go slow when docking. If you rush, you could damage your boat, the dock, or worst of all, another boat. If it’s not going well, don’t be too proud to back away and start again.

- Pack more food and water than you think you’ll need. You may be surprised by how boating works up your hunger and thirst. There’s no drive-through on the water, so make sure you’re well stocked.

- Valuables like cell phones, keys and wallets have a way of getting wet or falling in the drink. Make sure they’re secured.

- Leave a float plan. Things can go wrong on the water. Make sure if you get stuck out there, somebody onshore knows when and where to look for you.

- Always wear a lifejacket. The vast majority of boating-related deaths occur because victims were not wearing a lifejacket. It’s easy to do, and it could save your life.

- Have an onboard first-aid kit. When you are on the water, you can’t just run to the doctor’s office if you suffer an injury. Be prepared to treat yourself until you can get back to land.

- Have a tool box. If you have a mechanical problem when boating, you don’t want to be stuck on the water for hours waiting for help to arrive. Have tools and spare parts available so you can fix any problems yourself.

I’ve been listening to “The 7 Habits of Highly Effective People” lately, ….actually I’m on the second time through it. There will likely be many more times. Habit #1 is be proactive. In short: Work. Work on the things you can work on today. Do something every day to make your goal happen. Make work your habit. I suggest you put a picture up of your completed goal. You’ll see Chinese Junk Sailboats on my walls. Does it matter what you work on? YES, but there are 7 habits, this is just #1.

I’ve been listening to “The 7 Habits of Highly Effective People” lately, ….actually I’m on the second time through it. There will likely be many more times. Habit #1 is be proactive. In short: Work. Work on the things you can work on today. Do something every day to make your goal happen. Make work your habit. I suggest you put a picture up of your completed goal. You’ll see Chinese Junk Sailboats on my walls. Does it matter what you work on? YES, but there are 7 habits, this is just #1.