Specifications

* Maximum speed of tow will be 3.5 knots, about 355 ft/min or 108 m/min

* Maximum depth 3000 ft, 915 meters.

* Maximum cable length: 4000 ft, 1220 meters.

* Maximum cable diameter 1/4″ communication cable parried with a 3/16 synthetic

strength member bound together with a 2 inch wide fairing material

* Single speed drive.

* Electronically load sensor in order to release line and alert the pilot in the even the tow is fouled.

* DC Electric powered. Preferably 12v

Cable

4pr 24 gauge AWG 4 pair Cat 5E Direct Bury

Specialty cable for deep water ROV’s is very expensive so we are opting for using the common, inexpensive bury type Cat 5 computer network cable network with 4, 24 awg twisted pairs

We looked into making syntactic foam floats to offset the weight of the cable but they present an issue with tangling the line, not going on a spool, and not providing consistent buoyancy over the length of the cable.

A better idea was to use hollow braided polypropylene rope, which floats, and insert the cable inside the rope.

A better idea was to use hollow braided polypropylene rope, which floats, and insert the cable inside the rope.

Wet weight (weight in water) of 200 ft of Cat5 direct bury network cable is .4 lbs per 200 ft. The buoyancy for 100 ft of 3/8″ hollow braid Poly (polypropylene) rope is .4 lbs per 100 ft. So 200 ft of hollow braid would provide .4 lbs of positive buoyancy to accommodate for fresh water, compression and the little air bubbles that were trapped in the brad when I did the measurement. And we can weave yarn into the brad on the last 1000 feet to help counter strumming. Breaking strength of the Cat5 is about 500 pounds and the poly is about 500 lbs, working is 220 lbs. The OD of the poly over the Cat5 is .42″ (About 7/16″) which means 2000 ft will fit on our current winch drum.

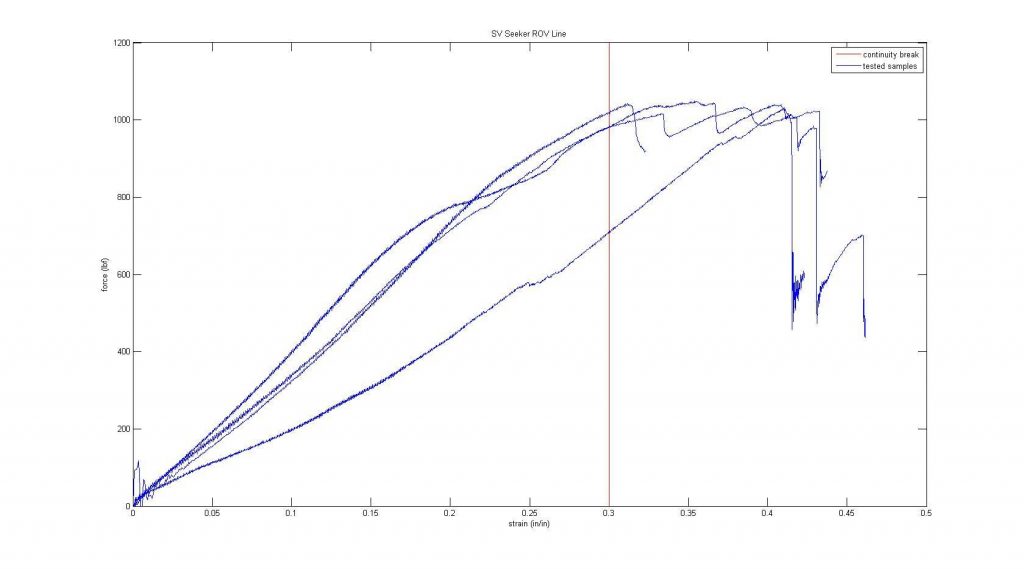

We put gel-filled Cat 5, bury type, network cable; 13 cents/ft, inside 3/8″ hollow braid polypropylene rope, about 10 cents/ft as it take about 120 ft of poly to cover 100 feet of Cat 5. The result was just slightly positive buoyant even in fresh water. The working load for the 3/8″ poly is only 215 pounds but we were hoping that the Cat 5 would increase that so I sent samples to Austin Downey to test and the results are in the graph. Ignore the elongation, we just tied a knot in the sample. But the good news is that it looks like we can sustain a working load of 500 pounds and we don’t loose communication till we hit 700 pounds, and we don’t loose the ROV unless we exceed 1000 pounds. Many thanks to Austin. Our later test generated much lower numbers on the Cat5 as it broke around 420 lbs, and I suspect that was due to testing a longer sample with less pre-tension in the hollow brained poly.

After several hours of work we had over 600 ft of gel-filled Cat5 direct burial cable inside 3/8″ polypropylene giving us a tether that cost only 23 cents / foot, takes 700 pounds before the before the copper conductors break and 1000 pounds before it completely parts.

The down side to direct burial cable is that it uses solid copper wire and not stranded copper wire. Stranded wire survives longer with flexing, but they don’t use it for buried cables. We like the gel-filled bury cable because it contains no air that will compress at depth and cause the cable to become heavier.

The down side to direct burial cable is that it uses solid copper wire and not stranded copper wire. Stranded wire survives longer with flexing, but they don’t use it for buried cables. We like the gel-filled bury cable because it contains no air that will compress at depth and cause the cable to become heavier.

We posted the video; Low Cost ROV Tether and more… and got two great suggestions.

Braids and Laces in Cannington, Ontario can weave the polypropylene rope around the Cat5 cable we supply for 193 Canadian, or $152 usd, plus maybe $100 in brokerage fees + 120 shipping. That will bring our poly rope cost from 8 to about 21 cents a foot, but save a day of work and hopefully improve the quality. So we are on the hunt for Gel-filled, stranded Cat5. If we can keep the Cat5 cost to 13 cents, then we end up with a great 300 pound towing tether for $340 per 1000 ft. Cable Sales Canada has the bury Cat5 we want as well as stranded conductor Cat5 to test. So 0.372 for the rope and braiding and .13 for the cable brings to total to just over 50 cents a foot. We are also talking to Atwood Rope in Ohio.

Another wiz bang suggestion from Bob Cartwright was to use polypropylene tubular webbing, and it is available from Shan Li Weaving . The upside of tubular webbing is that it will be easy to insert the cable, and even replace the cable when it becomes damaged.

Tubular webbing may also be the perfect answer to “cable strumming”, a phenomenon that occurs when round cable is dragged through the water. Uneven pressure builds on one side of the cable causing to to move to to low pressure, and that movement cause a low pressure on the opposite side, so the cable begins to vibrate. You may have see fishing line do this just before it breaks, because the vibration greatly increased the drag. The material in the tube will create a laminar flow around the cable and help prevent strumming.

When cables they start strumming the drag increases, and then the cable breaks. Video I’m hoping the tubular webbing on the ROV’s tether will act like a fairing similar to what the pros are doing: http://www.odimspectrum.com/seismic.html

100ft of poly only covers about 64 feet of 1/4″ Cat5. And 3/8″ poly weighs approximately .288 oz per foot, or 26.79 grams per meter. So the actual weight per foot is (100/64)*.288 = 0.45 oz or 41.86 g/m. Weigh of 42g/m translates to: 1.5″ wide by 2.3mm thick, 1″ wide by 3.2mm, and 1.25″ wide by 2.7mm. These are custom manufactured by shanliwebbing.com for 0.228 usd/yard, 0.076 usd/ft. The shipping is $610 for a 3000 yard spool bringing the cost to about 15 cents a foot. Add the cable and the total price is 27 cents a foot. Just 4 cents more than our cable in poly rope solution and possibly stronger and with much less time required for inserting the cable. We may also be able to easily replace a broken cable when using tubular webbing.

The Coax Option – 1+ Miles!

Coax like bury type Cat5 is widely available and hence a great value, but until I met Zach and Electrical Engineer at the Tulsa Maker Fair that told us about Ethernet Over Coax devices. Dual shield is about 6 cents a foot, quad shield about 13 cents.

TRENDnet Mid-Band HPNA Coaxial Network Adapter (TPA-311) 196Mbps, 1600 meters, $80 Will need to be modified to fit the hull.

Seco-Larm Enforcer Ethernet Over Coax with PoE (NE-AE01-030TQ) 10Mbps @984 feet, 300 m $165 Fits the hull.

IPC600 Octava Ethernet over coax Extender with PoE, 100Mbit, 2600 ft , 790 m, $199

EOC1110K Gigabit Ethernet over Coaxial Unmanaged LAN Extender Kit 112Mbps @ 2,952 ft, 900 m $300 Might fit with modifications.

ebay.com from China: IP/PoE over coax, 100Mb up to 8000 ft, 2500m $126 Fits the hull.

C4L6400-EoC-P www.c4line.com info@c4line.com

Another idea from Zach: ”

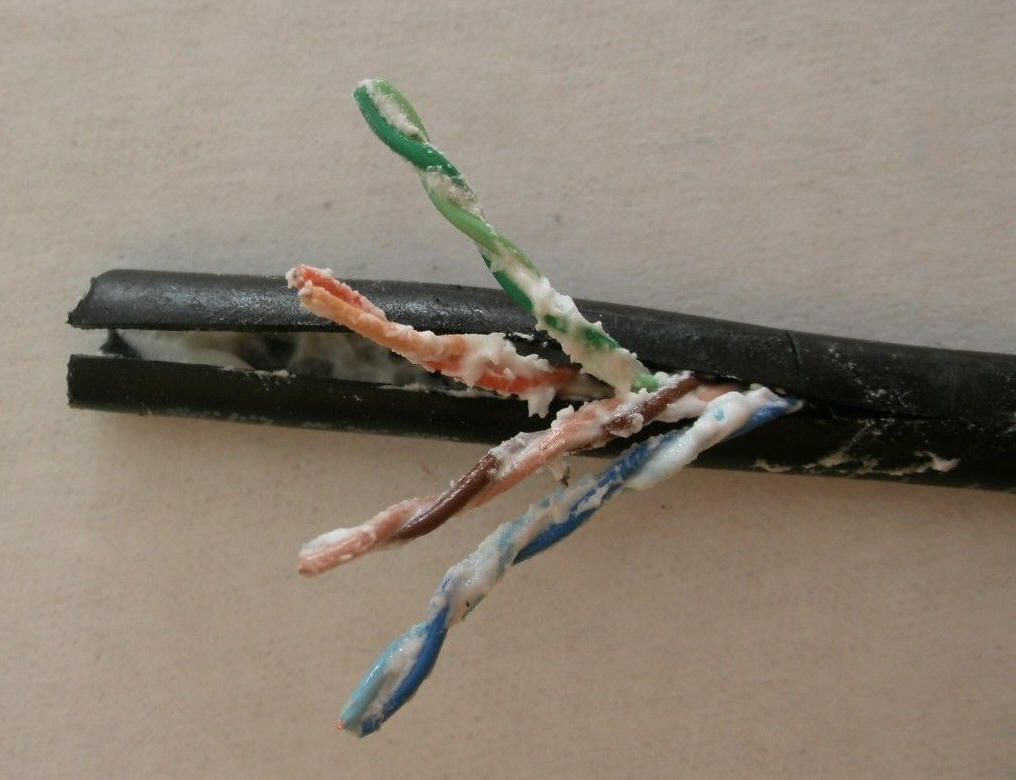

Cable Breaks inside Tubular Webbing

The samples have arrived and Shang Li Webbing says: “The 1″ is in thickness 2.9mm, weight 46g/m, tension strength value 934kgs. The 1.5″ is in thickness 1.9mm, weight 45g/m, tension strength value 769kgs.” That is over 2000 pounds of strength for the 1″ and 1600 pounds for the 1.5″ wide webbing. But we quickly found a problem with the first test. The tubing stretches 35% with 300 pounds without gripping the cable as the braided rope does it simply allows the cable to take the bulk of the load and the RG6 cable broke.

The industry recommended load for RG6 ccs, or copper coated steel core is 75 lbs, and 35 lbs for solid copper core. The actually breaking strength for RG6 ccs is just over 400 pounds. Much better than Cat5 solid core that breaks around 180 lbs. But even the stretching of coax will reduce it’s ability to carry a signal as the distance between the core and the shield are reduced.

We could add a 1/8″ Galvanized Steel Wire Rope, 7×19 Strand Core with a 0.029 lb/ft. The additional cost of the cable would be about 8 cents and as coax is about 0.0082 lb/ft, we would need to triple the volume of the webbing in order to compensate for the weight of the steel cable, adding another 24 cents. The total cost of the tether would then be about 60 cents a foot. Much higher but still half that of the lowest cost neutrally buoyant tether on the market and with a towing capacity of 1000 pounds.

3mm Dyneema at 50 cents/ft would be much better as it only stretches 2%. but the cost of the cable would double to 70 cents / ft.

| Cat5 solid copper | ||

| Lbs | Length | % Stretch |

| 0 | 145.500 | |

| 13 | 145.625 | 0.090 |

| 35.8 | 146.313 | 0.560 |

| 56.6 | 147.000 | 1.030 |

| 77.0 | 149.313 | 2.620 |

| Broke | ||

| RG6 dual shield, copper clad steel core | |||

| Lbs | Length | % Stretch | |

| 0.0 | 140.500 | ||

| 13.0 | 140.875 | 0.270 | |

| 35.8 | 141.000 | 0.360 | |

| 56.6 | 141.313 | 0.580 | |

| 77.0 | 141.688 | 0.850 | |

| 97.6 | 141.688 | 0.850 | |

| 117.4 | 141.875 | 0.980 | |

| 135.3 | 142.000 | 1.070 | |

| 153.8 | 142.125 | 1.160 | |

| 174.4 | 142.188 | 1.200 | |

| 190.6 | 142.375 | 1.330 | |

| 211.3 | 142.563 | 1.470 | |

| 209.3 | 142.688 | 1.560 | |

| 211.4 | 143.125 | 1.870 | |

| Broke | |||

| Cat5 solid copper, gel-filled, burial. | ||

| in 3/8″ hollow braid polypropylene. | ||

| Lbs | % Stretch | |

| 28.9 | 0.3 | |

| 49.2 | 0.7 | |

| 70.3 | 1.4 | |

| 91.0 | 1.9 | |

| 111.4 | 2.5 | |

| 131.4 | 3.0 | |

| 151.9 | 3.4 | |

| 171.4 | 3.9 | |

| 190.9 | 4.6 | |

| 211.5 | 5.1 | |

| 229.8 | 6.0 | |

| 249.4 | 6.6 | |

| 269.3 | 7.4 | |

| 290.1 | 0.0 | |

| 311.3 | 9.7 | |

| 331.1 | ||

| 350.5 | 10.3 | |

| 368.7 | ||

| 388.0 | 12.2 | |

| 406.9 | ||

| 425.6 | 13.1 | Cat5 Broke |

| 1400.0 | Poly Broke. | |