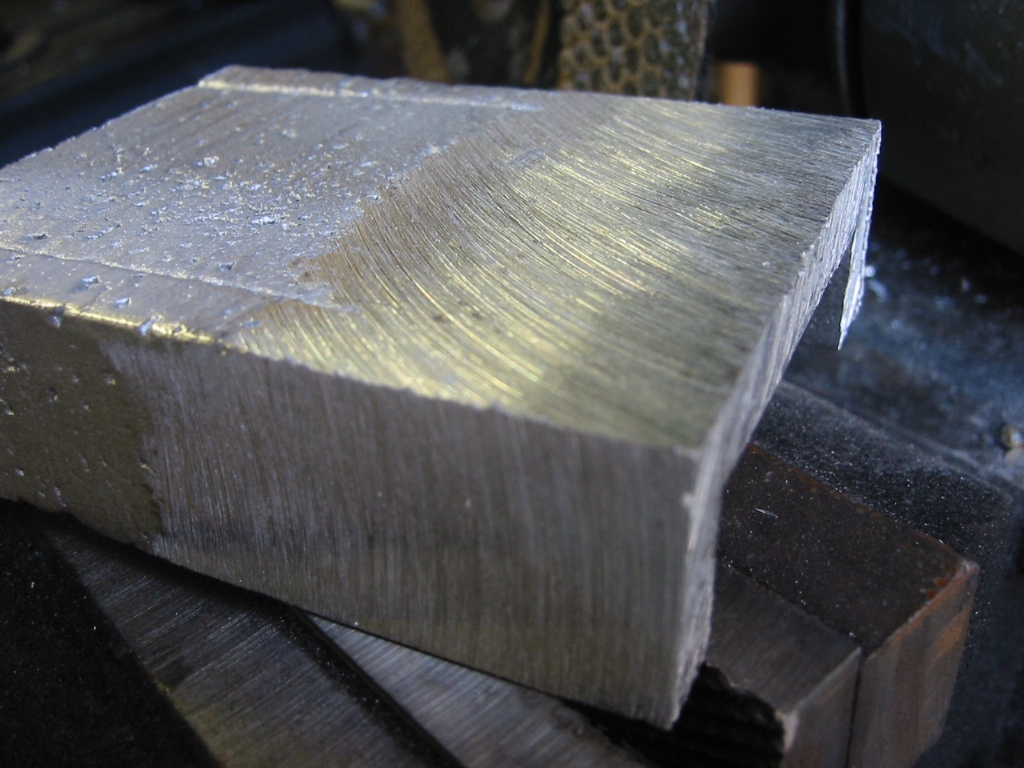

Lost Foam is the perfect casting process for building a few odd pieces. I created the lower cabin hatch hinges from a solid block aluminum using a table saw, so I know the time required to shape a custom piece by removing what you don’t want.

Building a foam part is a lot faster, and then it is just a matter of pouring in molten aluminum. You have to admit that it sounds good anyway. In reality there is a learning curve, but one you can reliably cast parts there is no going back.

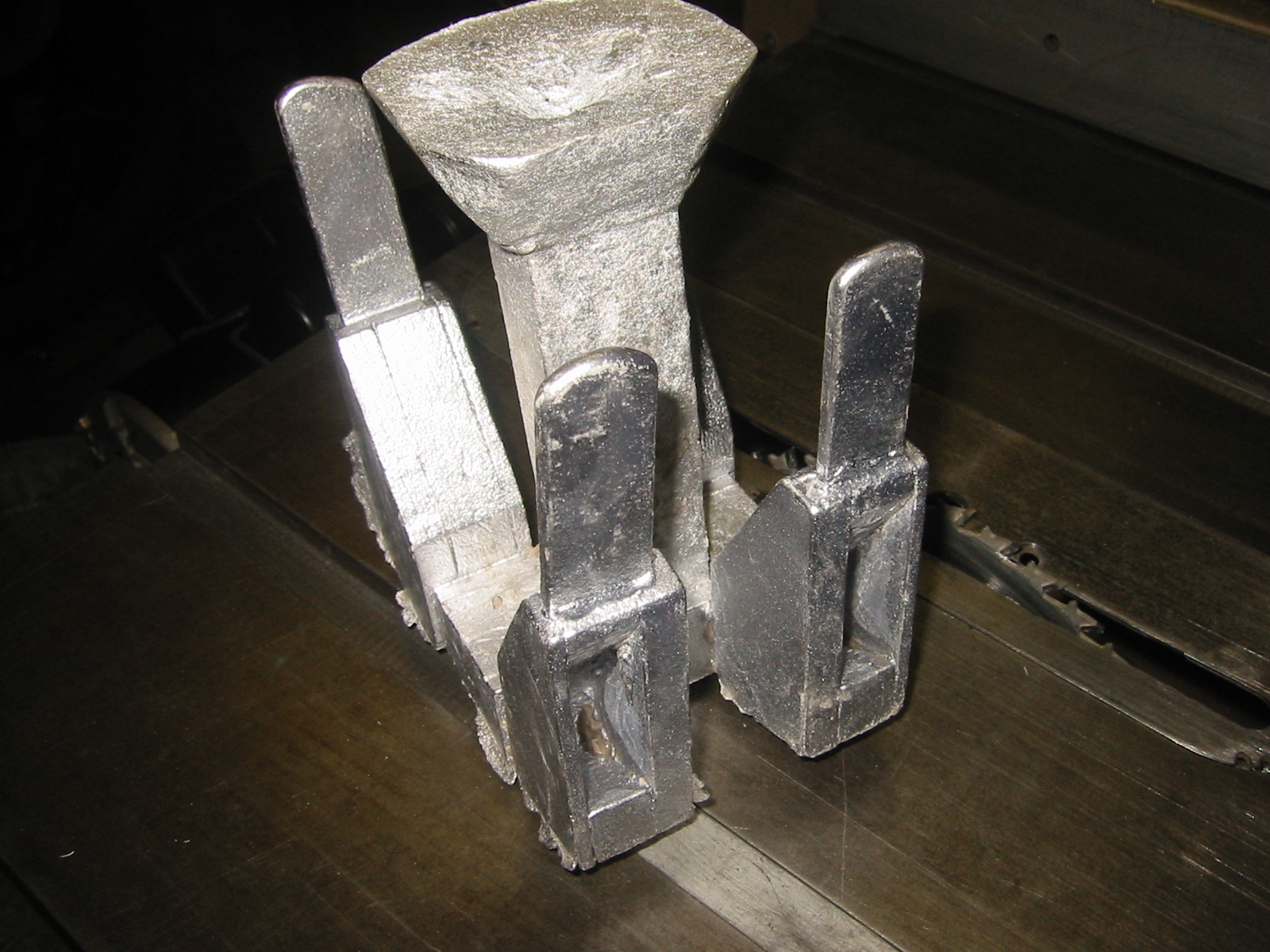

(1) First castings show lots of room for improvement

(1) My first cast frankly looks like crap, but that makes improving easier. The page below will show you my successes and mistakes as I when through learning lost foam casting. I think you will enjoy learning from my mistakes much more than recreating those on your own.

I started with a chuck of polystyrene from a local supplier, but you may be able find plenty in the trash bins behind appliance stores. The density of my test piece is 1 pound per cubic foot. They also have 2 pound per cubic foot. Denser foam will produce better surfaces, is easier to shape but will produce more burn off and ash. The foam was then coated with sheetrock mud and allowed to dry before the cast was made. The technical name for the sheetrock mud is “investment”. Investment is anything that you use to coat your foam part. Sheetrock mud works well for me, but you can also us Plaster of Paris, castable refractory, or specialized casting investment.

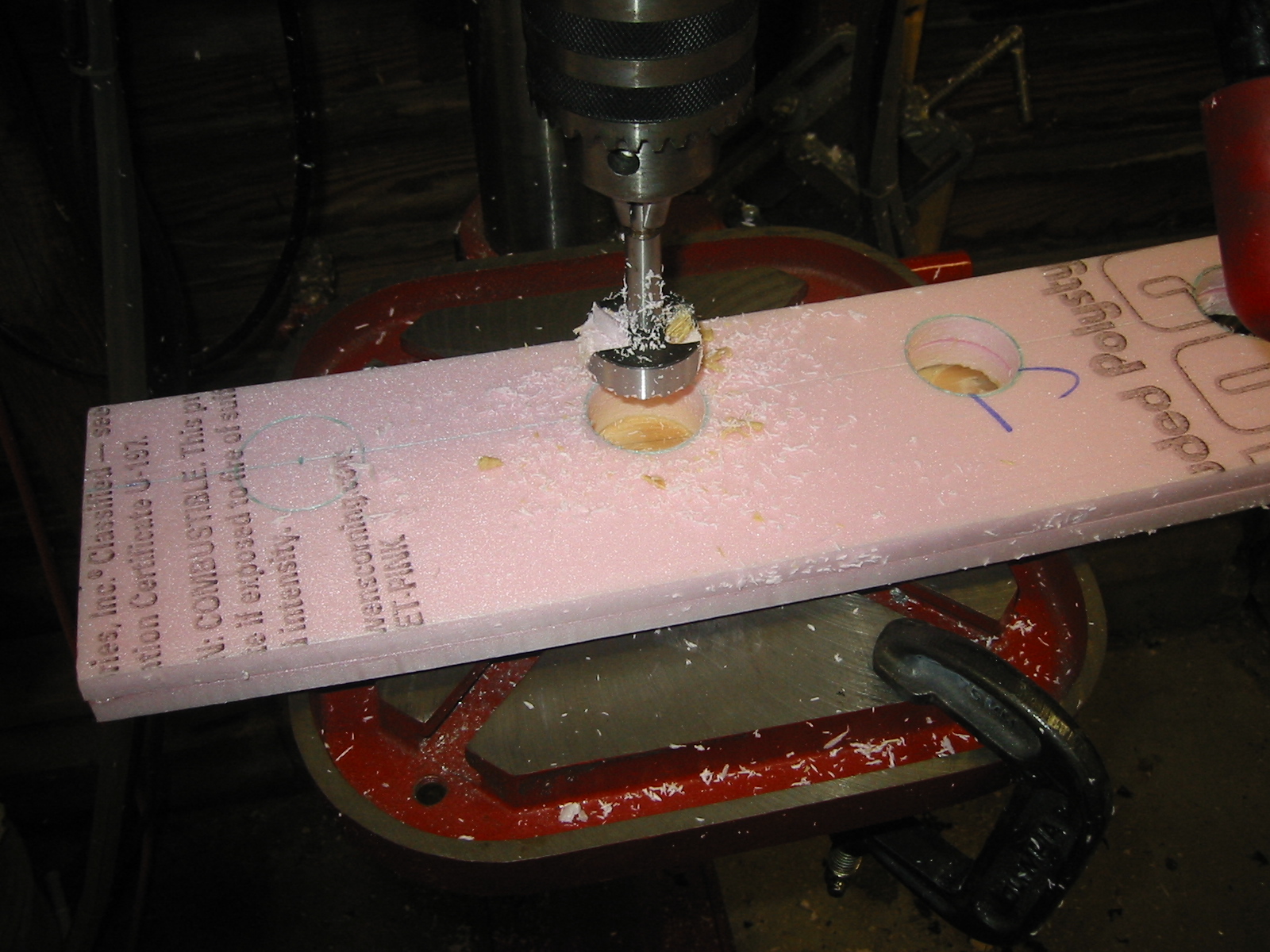

I also tested casting the threads of a bolt. After cutting the foam to to shape I burned some 3/8″ holes in it with a 1/4″ bolt heated up with a torch. The holes would be for 3/8 inch bolts. I then coated the bolts with soot by holding them over a burning rag that was soaked with kerosene. Diesel works well too.

After they cooled the bolts were then inserted in the foam and the whole thing was coated with thinned down mixture of sheetrock mud. The parts are placed in front of a heater vent to dry over night.

My mistakes were quickly obvious when pouring the casting. First, I did not have enough molten aluminum. One mold only half filled and the other was missing some at the top. I also poured too slowly; about 10 seconds for the whole crucible, and that allowed the aluminum to cool too quickly in the mold before it had a chance to flow completely around all of the bolts. Cutting one of the castings in half reveled a couple of bubbles inside. These could be from the aluminum being too hot, but more likely it is due to the slow pour. As the foam burns out it needs to vent so it is best to pour enough metal in that flow out the vent along with the gases created by the burning foam. My test parts only had a pour spout and no vent so much of the burn off gas is trapped inside. Next time I’ll have vents separate from the pour spout and I’ll let some of the molten aluminum flow through the part.

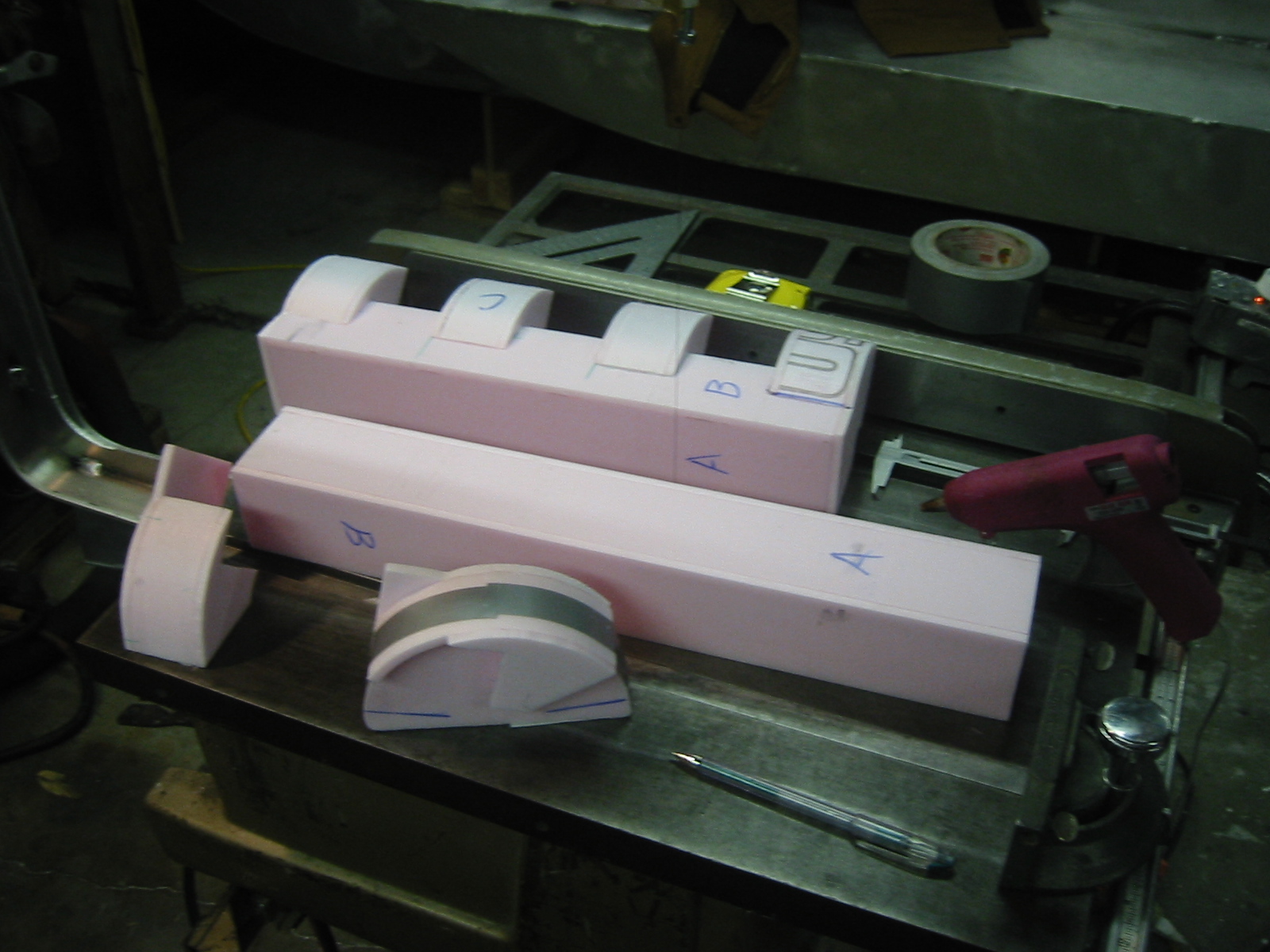

(1) The threads actually came out pretty good, almost as good as what I can do with a tap. The bolts required a strong tork to break them free, but only light pressure to remove them completely. The threads do have a few gaps, but once again it is likely due to the lack of vents and pouring too slowly. The outside cleans up nicely with a wire brush but even then you can clearly see the exact pattern of the Polystyrene pellets that formed the foam. I discovered sanding the the surface of the foam gently with 400 grit sand paper greatly helps to smooth and reduce the visibility of the polystyrene’s texture and it likewise improves the surface of the cast. Otherwise a light grinding quickly removes the foam pattern from the casting. The back, right corner of the part in the photo has been ground. Finally while it is possible to cut notches out of the foam using the hot wire cutter, it is easier to to get uniform thickness if the foam is cut into appropriate sized slabs which are then glued together.

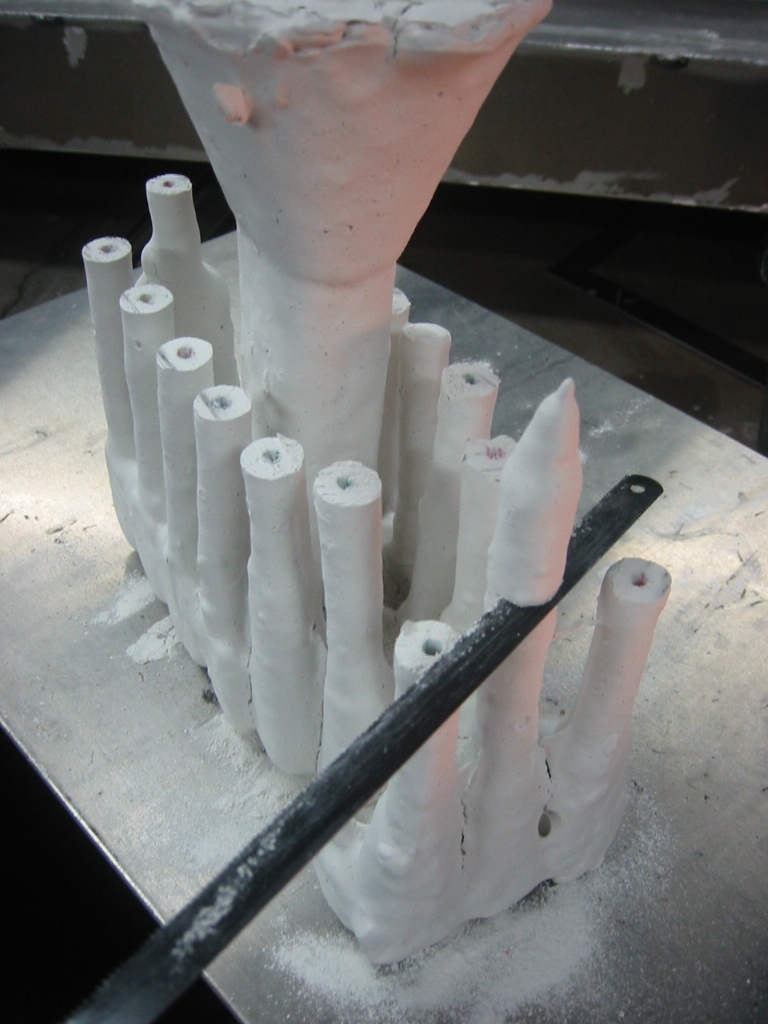

(2) I assembled a second set of parts to test. I keep a storage container filled with thinned down sheetrock mud. The foam parts are dipped and then allowed to dry.

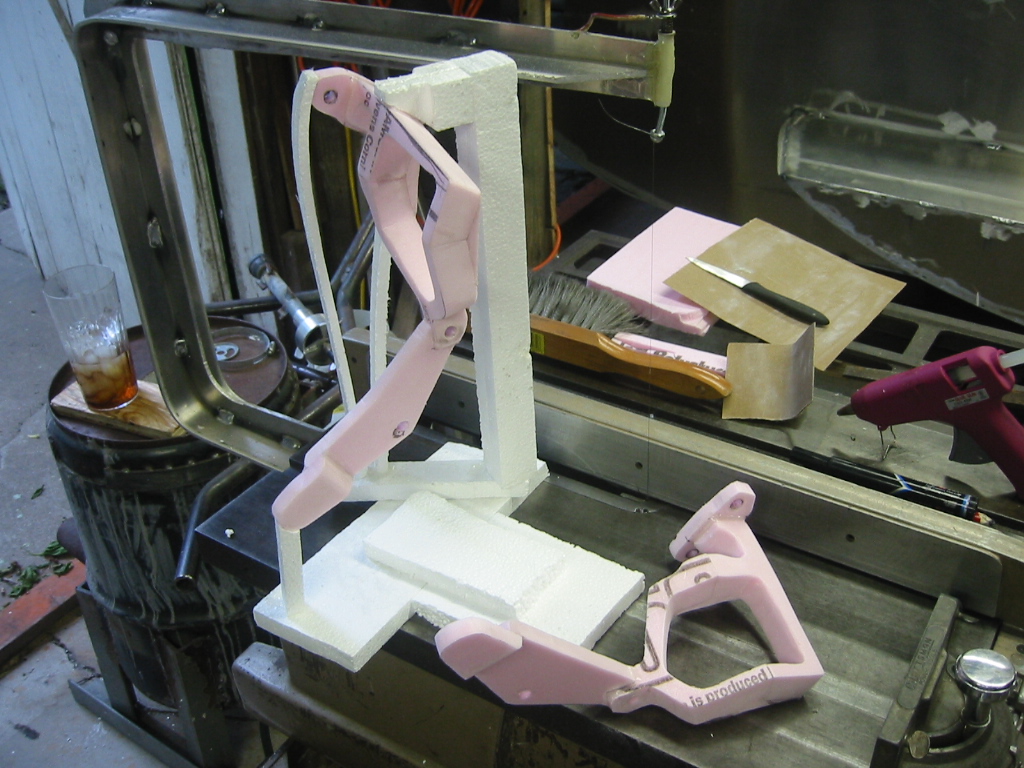

(3) I also built a “Krush Head Pressure Tool” as recommended by Dave at www.buildyouridea.com. He has a good Lost Foam Metal Casting Primer The design only varies slightly from Dave’s. The KHPT tool is placed on top of the sand around and it allows the molten aluminum to pool above the foam parts in order to add pressure and a reserve of material to be drawn into the casting as the aluminum cools and contracts.

(2) Foam parts drying after being coated with sheetrock mud.

(4) Crucible charged with scrap.

(6) Sand covers the parts with the vents and spures exposed.

(6) Sand covers the parts with the vents and spures exposed.

(8) Jack stands make a nice rest of the crucible so that it is not set on the concrete.

(10) Skimming dross of the surface of the molten aluminum.

(12) Hooking the crucible.

(3) Tool to form pool of metal above the parts pour spout.

(5) Two test parts are set on a bed of sand with the pour spouts or “sprues” close together so they can be poured together.

(7) The head tool is place over the sprues.

(9) Additional pieces of scrap aluminum can safely be added as long as they are dry.

(11) The skimmer is a pipe with a shorter piece of pipe welded to the end to from a Tee.

(13) Rotating the handle.

The lock that holds the tool closed is a piece for 1 1/2″ pipe that is flattened and cut lengthwise. It is shaped to slid up both handles when they are closed and the handles actually angle slightly inward toward each other as they come out from the 4″ pipe so the lock gets tighter as it slides in toward the 4″ pipe. The hinge is make from a piece of 5/8″ bar and 4, 1 1/4 inch long pieces of 3/4″ pipe. You simply weld every other piece to the other side of the 4″ pipe.

(4) Ready to make a some more test pours, the first step is to fire up the furnace a put on some aluminum scrap. I already learned that aluminum shavings from the table saw create a lot of unusable dross. So that and drink cans are worthless too. Those are saved for the recycle yard.

(5) While waiting for the aluminum to melt the parts are prepared. The mud coating over the foam has completely dried, and a pair of parts are set into a few inches of sand. The plan is to pour both at once and fill them until molten aluminum flows out of both risers. The risers are made from foam, just like the rest of the part but they will be cut away from the part after the pour. The aluminum will be poured into the two risers that are positioned closest together, technically these are called “sprues”.

(6) More sand is added to burry the parts and a good attempt is made to shake the tub in order to vibrate the sand into the crevasses around the parts. You never get too old to play in the sand box!

(7) The Krush Head Pressure Tool is set in place around one sprue from each part. The sprue rises about 1/2 inch above the sand. When the aluminum is poured it will cool on contact with the sand and then fill the bottom of the KHPT until is starts to burn the foam out and flow down into the part.

(8) Jack stands make a nice rest for the crucible. Setting the hot crucible on the concrete. You can add another level of safety by putting your furnace and casting area over a bed of dry sand. If the crucible breaks, or if aluminum is spilled onto concrete, the heat will vaporize the water in the concrete in as little as 2 or 3 seconds, causing it to explode or “spall” and fling chips of concrete and hot aluminum through the air. Just setting a newly cast piece on the concrete to cool will cause spalling.

(14) Lost Foam Casting

(9) Once the aluminum starts to melt in the furnace it goes fairly quickly. You can add pieces of aluminum thought the site hole in the top of the furnace and watch as they slowly slip into the melt. Just make sure the scrap is dry. The scrap I am using is 3/16 inch 5082 and 5086 aluminum alloy sheeting from the submarine I am building. If you have a choice you should use 4000 or even 6000 series aluminum. These have more silica and will flow better. (10) Any dross is skimmed off the top of the melt. (11) My skimmer is just a steel pipe with a short pipe welded onto the end to form a Tee, and flat piece of steel on the end works even better.

(15) Aluminum vented through only one of the vents.

(17) Chipping off the mud

(19) U-Channel made by gluing slabs of foam together with Hot Glue.

(16) Pulling the part out.

(18) A sifter is used to clean the chips of mud out of the sand.

(20) Sanding the foam with 400 grit sandpaper helps smooth the surface. The remainder of the texture left by the foam can be removed with a grinding disk.

(12) Once comfortable that there was plenty of aluminum in the crucible, we were all set to pour. (12) The first step is to hook the crucible seen in the photo below and left. Maybe next time I will remember to put the face shield down and not just wear it on my head. Things are not really as hot as I expected but I still like the fact that this tool allows me to stay far away from the crucible and off to the side.

(13) Rest the tool on the jack stands and rotate the handle to bring the swing arm into contact with the crucible. …and look who remembered the face shield!

(14) WARNING: foam gasses burst into flames! The first lesson is to warn your camera person; my wife 🙂 that flames are involved.

(15) The problem is that once the molten aluminum burned thought one of the vents it quickly relieved the pressure built up by the head tool and aluminum poured out of the one open vent. So the second lesson is to make the vents the same height as the head tool or open them up so they all vent at the same time. In this case the second piece did completely form, it just never filled the second vent sufficiently to reach the surface.

(16) (17) After cooling for several minutes the parts are pulled from the sand. You better be wearing good gloves! The mud is easily removed from the part, but you can see a problem between the letters “A” and “Y”. I don’t think I got enough sand in the crevice there to support the mud and the aluminum broke through. Facing this side up is part of the solution, as well as taking more care to vibrate the sand into all the recesses, or reinforce the mud. I learn latter that the mud works best for me if there are several coats applied with a day between each in order for it to dry. Subsequent coats should can as be thicker. Do be sure the mud is dry. If not, it will generate steam when the aluminum is poured in and the blow the hot aluminum back out of the mold. That was exciting!

(18) The chips of left over mud are sifted from the sand and we are ready to go again.

(20) Having tried to cut a uniform notch out of a block of foam I decided to try cutting the foam into slabs and then gluing them together to form a channel. I tested Polyurethane Adhesive and Hot Glue for bonding the slabs, and the Hot Glue definitely worked the best. Hot Glue also dries fast and is much easier to work with.

(20) I also experimented with sanding the foam with 400 grit sand paper before coating it with the mud, and while you can still see the pattern from the foam beads, the sanded surface was much smother. A little grinding with an aluminum grinding disc and the surface looked great.

I made several cross cuts through the test pieces and I did not find any voids. I believe faster pour rate, the generous amounts of molten aluminum flowed thought the piece and the added pressure from the KHPT each helped to eliminate the problem with these test pieces. Finally I think I am ready to build something real. The really nice thing is all of the test pieces just get recycled.

Vents

The following test clearly shows that sufficient vents needed to ensure a good flow of aluminum through the part.

(1) A mud encased 14 inch foam ring with a spur 4 vent and the foam dissolved failed to completely cast.

(1) I tried casting a 14 inch ring that is about 1 3/4 inch wide and 1/2 inch thick. It had 5 vents and the vents were first opened up by pouring a little acetone into each one. This allowed the pressure to be relieved before the aluminum reached the top of the vent. The part did not blow out like some of my test pieces. It almost worked but as you can see in the photo, it did not complete the last 5 inches of the ring, leaving a gap between the farthest two vents. I poured this piece quickly, knowing the aluminum had a long way to flow, so I’m not sure what the answer is yet.

(2) Additional vents and runners helped but a pocket was still poorly formed.

(2) After getting some advice from the from the Yahoo hobbicast forum the second attempt employed 4 spokes from a center riser along with 8 soda straws on the ring in order to vent the burn off gasses. It worked much better. In the photo you can see a black spot on the left where a void exist between two of the straws. The mud mold also broke again, but the large protrusion was easily cut away. The foam for this part is coated with sheet rock mud thinned by 50% with water.

In hind sight the best solution for casting a ring is to not use a mud coating. Using mud the gas and air from diffusing into the sand. Using the Lost Foam Casting in Sand process described below would have solved the problem. However if the aluminum can flow through a part without trapping gas then coating the part in mud and dissolving the foam is a useful process because it produces parts with a smooth surface.

Lost Foam Molds

(1) Multiple small foam parts each with a drinking straw attached for a vent and then all attached to a shared runner and spur.

(3) Heat above 200 degrees during the drying process will cause the foam to swell and the mud will split open.

(2) Sheetrock mud coated parts drying in front of a heat lamp. Others are drying in an oven at 175 degrees F.

(4) Trimming off the drinking straws. The parts have been coated with multiple layers of sheetrock mud.

(1) (2) I did a couple of more test, and they were both educational. First off – Sheetrock mud works fine as long as you keep adding coats until there is 1/4 thick layer of mud. Essentially, this process uses the foam to create a durable mold. The foam is then dissolved with acetone before the part is cast. The mold can then be pre-heated and has no problems venting during the pour.

The first coat can be and needs to be thin if there is detail in the piece. Plaster works well too but its harder to work with due to its quick drying time, it cost more than sheet rock mud and you’ll have a lot more waste.

Moisture is the enemy when pouring 1300 degree aluminum into a foam part coated with mud. I placed the parts in a oven to dry and set the oven on low, which is just under 200 degrees in this case and left them for 4 days.

(3) Most of the parts did fine, but one of them split open like an over rip melon. It seams that the foam can swell when heated. It turn out with subsequent testing that 175 is too hot too, at least for the parts closest to the heating element. So if your not using your wife’s new convection oven then 125 is my recommendation. This part had a coating of about 1/8 to 3/16 of an inch. The other important lesson is to assure that the mud is completely dry.

I had several parts arranged with 1/4 inch separation between large 2 inch wide flat sections. After a few coats, the mud completely filled the space between the parts, but with no external surface it did not dry even after days under heat lamps. I washed out the foam with acetone and it quickly dissolved the foam and then the mud on the inside of the group of parts. When I turned the part over to pour out the acetone, a large glob of mud also poured out onto the floor. So it is best to avoid placing that parts that trap mud between two surfaces.

(4) Once the mud is dry and 3/16 inch or better thick you can cut the vents open and pour in acetone to dissolve the foam. This works better if you are using styrene foam, the white stuff, than it does if you are using the pink insulation form commonly sold at the hardware stores. The foam is not really remove so much as it is converted it into a goop with the consistency of used chewing gum, that sticks to the insides. But with the vents open, then as soon as you start to pour in the aluminum the burn off gasses and steam can easily begin to vent. Also since it is important to make sure the part is dry, dissolving the foam allows for air to flow though the part. I first blow air through using an old dryer blower, then and only when I am sure that all of the acetone has been evaporated, I place the part back into a warm oven for a final drying. Be sure to keep in mind that acetone is extremely volatile and if placed in an over it could easily explode.

Also if you’re going to dissolve the foam with acetone and you are gluing the parts up with hot glue, then only use a minimum about of glue. Do not coat the entire joining surfaces since the acetone will not dissolve the hot glue and will be prevented from reaching the foam on the other side of the joint. This is especially true for small joints such as where a soda straw is glued to a foam part in order to provide a vent.(4) Once the mud is dry and 3/16 inch or better thick you can cut the vents open and pour in acetone to dissolve the foam. This works better if you are using styrene foam, the white stuff, than it does if you are using the pink insulation form commonly sold at the hardware stores. The foam is not really remove so much as it is converted it into a goop with the consistency of used chewing gum, that sticks to the insides. But with the vents open, then as soon as you start to pour in the aluminum the burn off gasses and steam can easily begin to vent. Also since it is important to make sure the part is dry, dissolving the foam allows for air to flow though the part. I first blow air through using an old dryer blower, then and only when I am sure that all of the acetone has been evaporated, I place the part back into a warm oven for a final drying. Be sure to keep in mind that acetone is extremely volatile and if placed in an over it could easily explode.

Also if you’re going to dissolve the foam with acetone and you are gluing the parts up with hot glue, then only use a minimum about of glue. Do not coat the entire joining surfaces since the acetone will not dissolve the hot glue and will be prevented from reaching the foam on the other side of the joint. This is especially true for small joints such as where a soda straw is glued to a foam part in order to provide a vent.

(6) A tablespoon of flux was tossed in, pushed down and mixed in, and then the dross is skimmed off the top.

(8) Still burning after the pour.

(10) Get your hot muffins.

(12) Handles and o-ring housings for the front hatches.

(14) Hatch parts installed.

(5) I started with the melt a hotter than what I had been using. This batch is just starting to glow orange. I am also using flux from www.budgetcastingsupply.comsince this some of this aluminum has now been cast once or twice, perhaps more.

(6) To add the flux I just toss in a tablespoon and then push it down and mix it in with my dross tool. The dross tool is round piece of sheet steel welded onto a steel pipe handle. I can’t tell that the flux did much good, but it is comforting.

The parts where set in sand and inspected by Sam (the dog). She looks worried. Perhaps she knew that I stood little chance of pouring a 10 lb pot of molten aluminum on the end of a five foot pipe and hitting the 2 inch opening of the of the riser. I originally had cone shaped funnels on the top of the risers, but these broke when I was melting the foam out. In any case next time I will have a bigger target.

(7) Sam may have also realized that the foam gum still in the mold was going to shoot 5 foot flames out the vents when hit with the aluminum. Anyhow she was not around during the pour. (8) Unfortunately, having spilled so much on the surface, I did not have enough to fill the last mold. I should have known that and waited, but the flames were too entertaining to resist.

(9) The next day another batch is poured. I added a blower to keep the flames pushed back. My blower is salvaged from a cloths dryer, cost $0, and it did a great job. One part still has its mud cast funnel and the other had the vents far enough apart that I could use the head tool. It’s much nicer having a bigger target and the smoke and flame blowing the other way.

(10) It’s also nice to have more melt on hand than needed. A steel muffin tin works great for casting ingots from the left over melt. But don’t set it on concrete or the heat will cause spalling. Of course 2x4s will burn, but that is manageable.

(11) I successfully poured carriage parts for the ballast sled. These are simple C-channels, but they really came out accurate and looking nice. There were 5 separate pours for 8 parts, and 100% success. Some of these same parts failed on the first attempt. The difference this time was better vents. I used 2 drinking straw vents at the top only 2 inches apart. Or wide vents made from narrow strips of foam. The foam was again melted with Acetone so they could breath immediately when the pour was started.

All of the pours were completed within 3 hours. Once the furnace is hot it’s much faster melting new material. And the time between pours is just right for allowing the previous part to harden, set up the next part, and cool off some. I kept plenty of melt in the pot and allowed material to flow out the vents and pool in the sand. Once the extra material solidified, the sand could be brushed off and the aluminum added back into the crucible along with new raw material. New raw material is stacked on top of the furnace in order to make sure it is dry and to start letting it pick up some of the heat. It’s then dropped into the melt though the site hole when there is enough space in the crucible.

Tips

-

Aluminum shrinkage factor is usually 3/16″ per foot. Or about 2%.

-

The thinnest you can cast is about 1/8″ for small castings.

-

Aluminum melts around 1300 degrees, and your suppose to pour at about 1350 just above the melting, but I have the best luck when its starting to turn orange.

-

Steel can be used in the mold but it needs to be covered with a layer of soot from a candle or torch to act as a release agent.

-

Risers should feed the thickest areas of the part so that material can be drawn from the riser as the part cools and shrinks.

-

Your riser must be larger than the part you’re casting so that it freezes last.

-

Never feed into the thin section because it will freeze first and block off flow to the thicker sections.

-

Put vents within 1/2 an inch of the corners at the top of the part.

More: “Secrets of the Lost Foam“

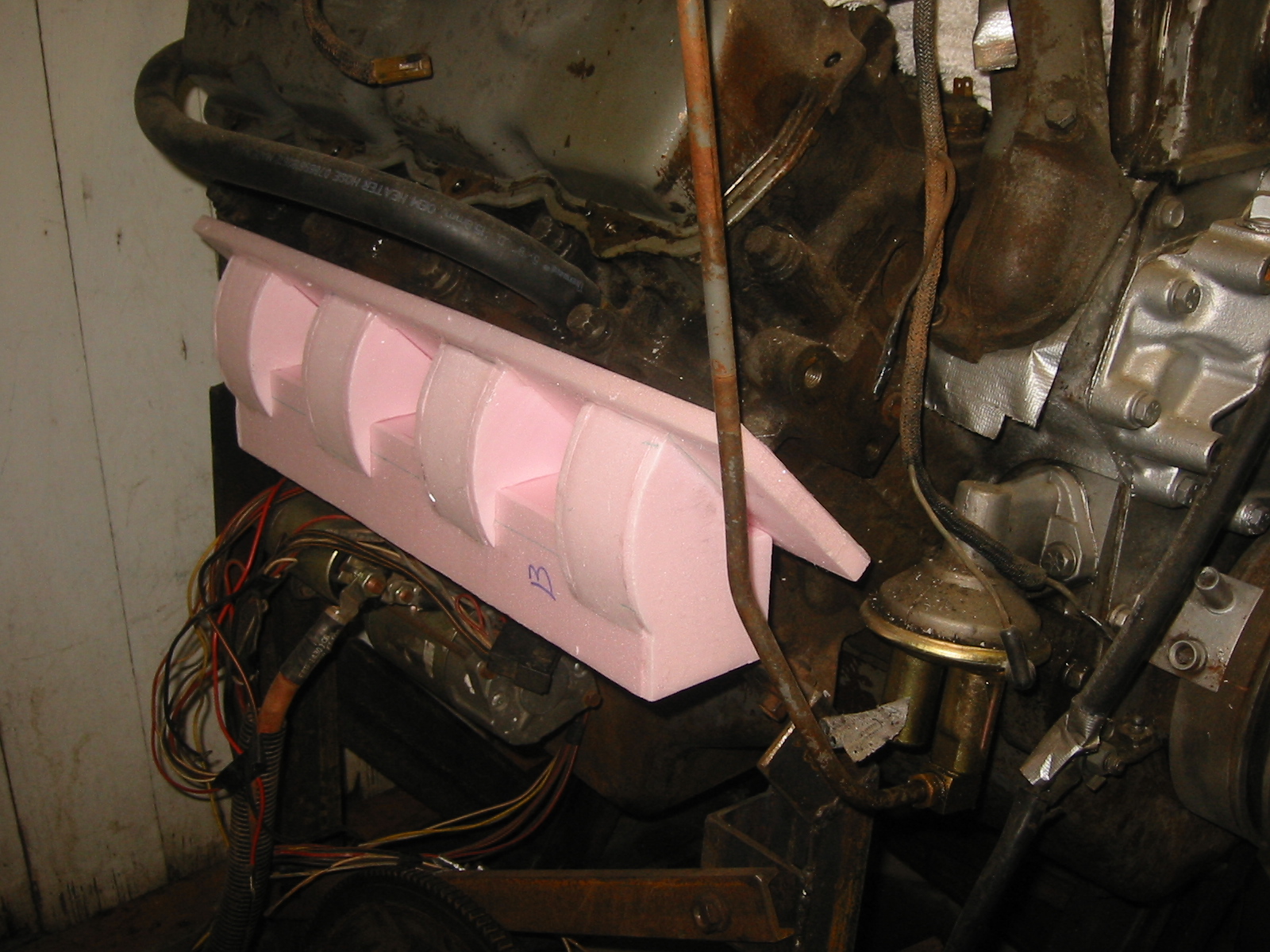

(1) This odd looking part is an alternator bracket for a Ford 7.3 diesel engine. I made a rough foam model and the made up two foam parts to cast in anticipation of screwing up one of them. Good thing too. On the first one one tall sprues feed the bottom center of the part and 2 long vents connected to the both sides of a flange. In the photo, the first part is upside down from how it will be poured. The sprues and vents are temporary glued to a foam base to make it easier to apply the mud coating. This is very different than sand casting where the part lays horizontally. The idea is to pour the part form the bottom up in order to allow the burn off gasses to vent as the aluminum rises inside the part.

(2) It worked fairly well, but once the part was full, gas pockets were still trapped inside and much of the flow of aluminum was diverted to the vents leaving a poor finish in the highest section of the part. It might have turned out fine, but I bumped it with the crucible while pouring it and broke off the top.

On the second part I connected the sprues to the bracket’s flange and only added a small vent to the top of the part. (2)In the photo, the first attempt is next to the hammer and the second and usable part is in the foreground. You can see one small void on the part. The trick to here was using lots of melt. Once aluminum was flowing from the vent I noticed the gas pockets were still venting as well, so I just kept pouring until I did not see any more pockets of gas venting. In the end there was much more aluminum laying in the sand than what was actually in the part, but the part was great.

(1) Alternator bracket

(3) The mold has be fired in the foundry after the foam was dissolved with acetone.

(2)

(4) The Resulting part is the best yet. Some of the walls on this part a 1/8 inch thick and all of them were completely formed.

(2) If you click to enlarge the photo, you can also see a small ridge near the flange. After the foam was dissolved with acetone I accidentally broke the mold, but I was able to put it back together by coating the broken area with generous amounts of Plaster of Paris. The ridge is where the aluminum seeped into the crack between the broken parts.

Eureka!

(3) I had been thinking about burning the foam out of the part before the pour and had tried it using the burner with little success. Having read about removing wax from lost wax molds on the hobbycast forum, I decided to experiment with a couple of mud covered foam parts I ended up not needing.

The parts where made from high density foam and repeatedly coated with thinned sheet rock mud and allowed to dry until a 1/4 inch layer of mud encased the foam. Before burning out the foam, it must first be dissolved with acetone. This reduces the foam to a gum like residue on the walls of the part. The foam expands when heated, just like wax, so melting it with acetone prevents it from splitting mud apart. I then allowed the part to dry for 24 hours in a 120F degree oven. This allows the part to dry from the inside. Then place the part into the furnace with the vents facing down. As the part heats up the foam residue will melt, flow out of the vents, and then burn away. After only 15 minutes or so the smoke will clear and the heat can be turned off. Leave the part to cool slowly in the furnace. A few hours latter you can remove the part, which will now is essentially fired pottery and any remaining ash can be blown out. These are delicate parts, much more so than real pottery, after all this is sheet rock mud, and not clay.

I buried the part in sand for safety and to provide a little extra support. I poured with no bubbling, no smoke, no flames, and so the normal flowing of massive amounts of molten aluminum through the part in order to carry off all of the gas bubbles was not needed. There is a movie above from pouring a set of parts were the foam was not not pre-burned. If you saw that movie then you’ll understand just how boring this pour was.

(4) The result is spectacular, even the 1/8 inch thick vents look great. The surface is very smooth with every detail of the original foam part. You can see the fine lines where the foam was glued together but also the lines in the sooth that remained on the mud after the foam was burned out. These parts are receivers for hatch dogs if you were wondering and the thin side of each of the 4 receivers is only 1/8 inch thick. The only blemish among the 4 parts in the set is shown in the photo. I looks like an air pocked formed inside the receiver as the mud the layers were being applied and this pocked filled with aluminum. You can also see thin ribbons of aluminum on the some of the outside corners where the mud must have cracked during drying.

Investment

(1) Plaster and silica investment applied to exhaust manifolds.

The investment is whatever you use to coat the foam, and so far I have mostly used sheetrock mud after having thinned it down with water so it was easy to brush on or dip the part in. I have also used plaster over the mud where I needed to fix a broken vent or add some structural stability.

The good thing about sheet rock mud is that it is already in a liquid and it does not harden in 10 minutes or so like plaster. The bad thing is that is takes days of dipping, and drying, and dipping again, and again in order to build up a 1/4 inch shell. It is not always necessary to build up a shell that thick. If you and set the part in sand and get the sand in contact with all of the surfaces so that it can support the think mud shell, the a thin coating of mud will work. However I have found that a few more days and a thicker shell means a much higher change of success on the first attempt. If you really want the part fast, and you are not overly interested in a smooth surface, you can also place foam directly into Petro-Bond or even regular sand and allow the metal to burn it out. You can read more about that below: Lost Foam Casting in Sand

(2) Firing investment in a temporary firebrick kiln.

(1) I should have left good-enough alone and stuck with the sheetrock mud, but I decided to try a mixture of 1 part fine white silica sand or silica flour and 1 part molding plaster which is also known of as “Plaster of Paris”. I read about using silica in the mix because it allowed for better thermal expansion of the mold. I unfortunately tested this mixture on two exhaust manifolds that I spent many hours cutting and gluing together.

(2) After letting the part dry for a few days I placed it in an kiln and over a few hours raised the temperature to somewhere around 1000 F. Unlike sheet rock mud the plaster and silica mix actually weakened and cracked badly. I have one more part that uses the same investment mixture so I dry it to at 150F for a few days and then try it in the kiln. Perhaps my problem was just too much moisture? No, I dried the next piece to a crisp and tried it again but got the same results. Plaster/Silica flour does not take heat!

Casting a Gearbox

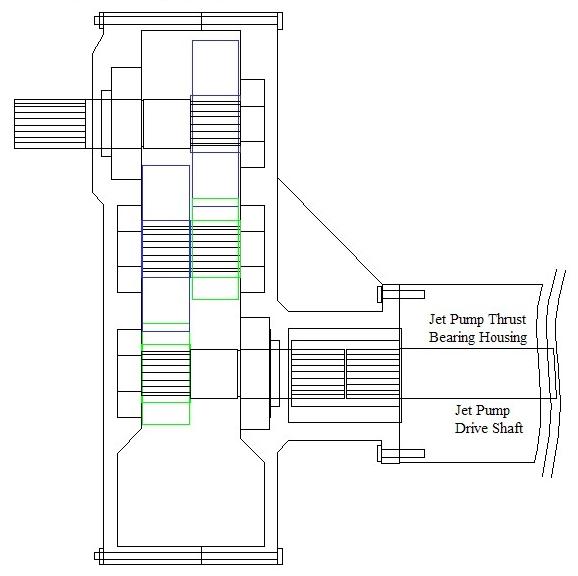

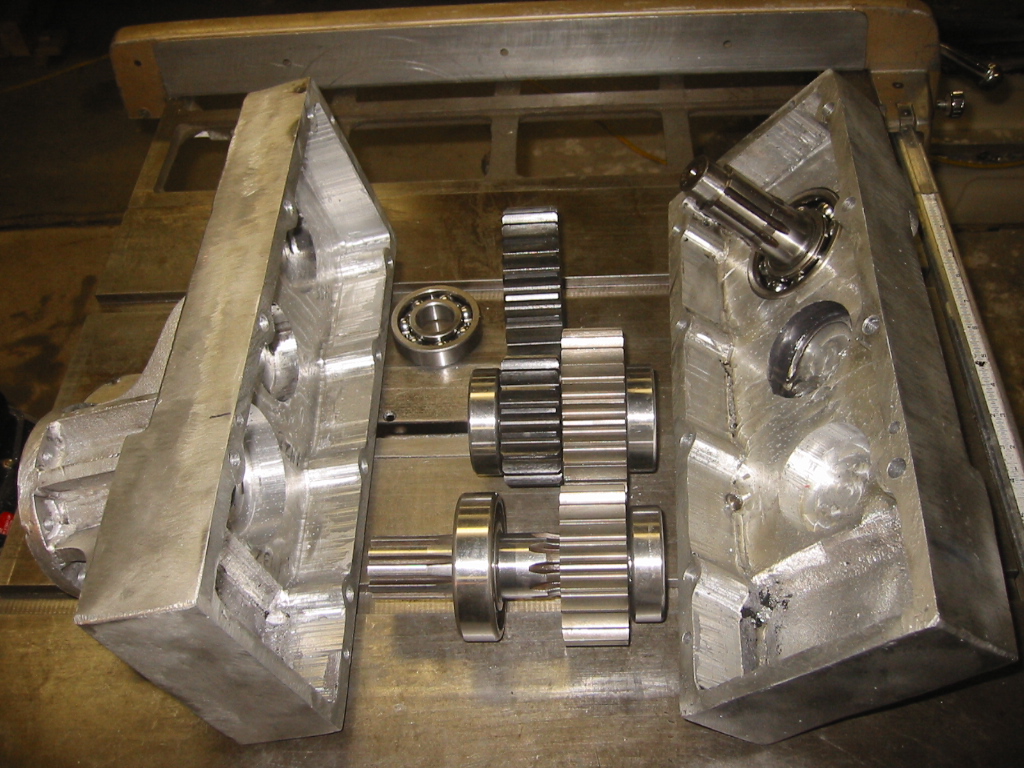

(1) Gearbox / Speed up box.

(3) The first few coats of mud were applied with the 2 halves together to insure the alignment.

(5) Storage container of mud, meat smoker for drying small parts and a firebrick kiln for bigger parts.

(7) Parts after they have be fired in the foundry to harden the investment and burn off the remains of the foam.

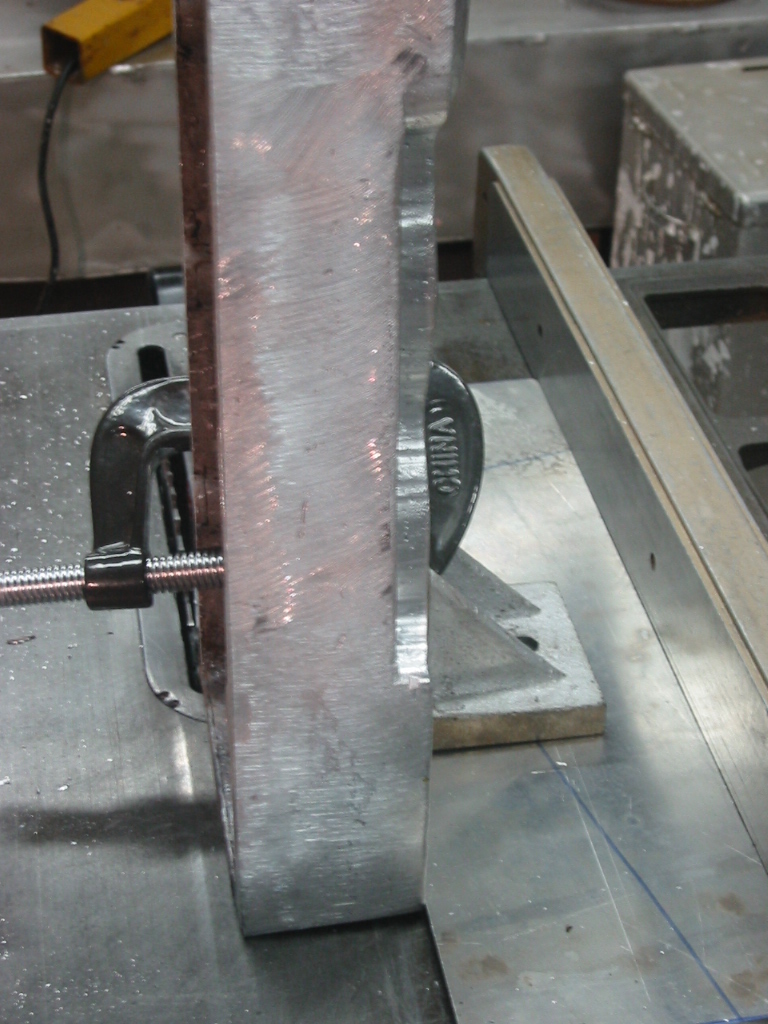

(9) Trimming the mating surfaces on the tablesaw.

(11) Using a jig to cutting recesses for the bearings,

(13) Completed gearbox.

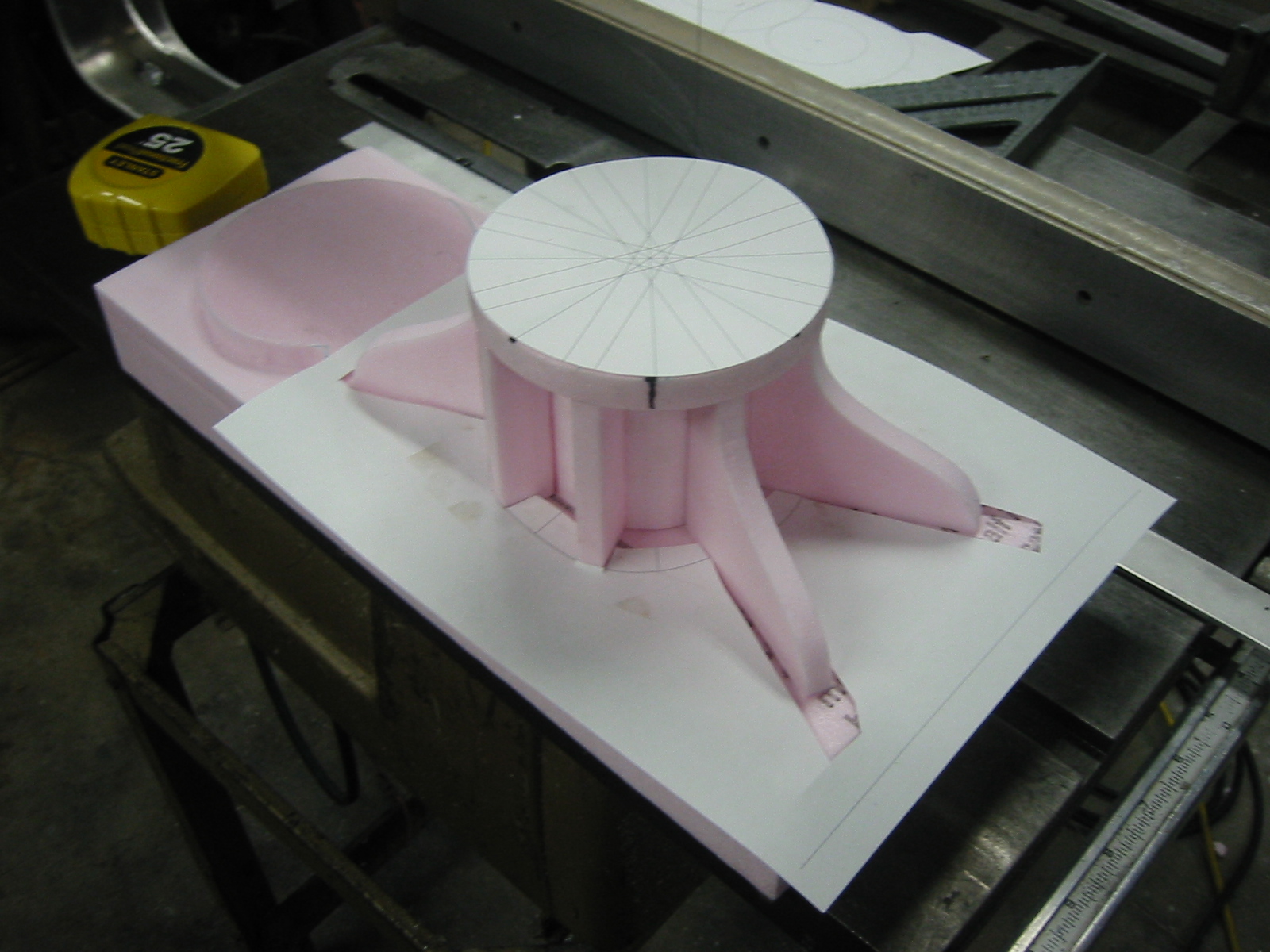

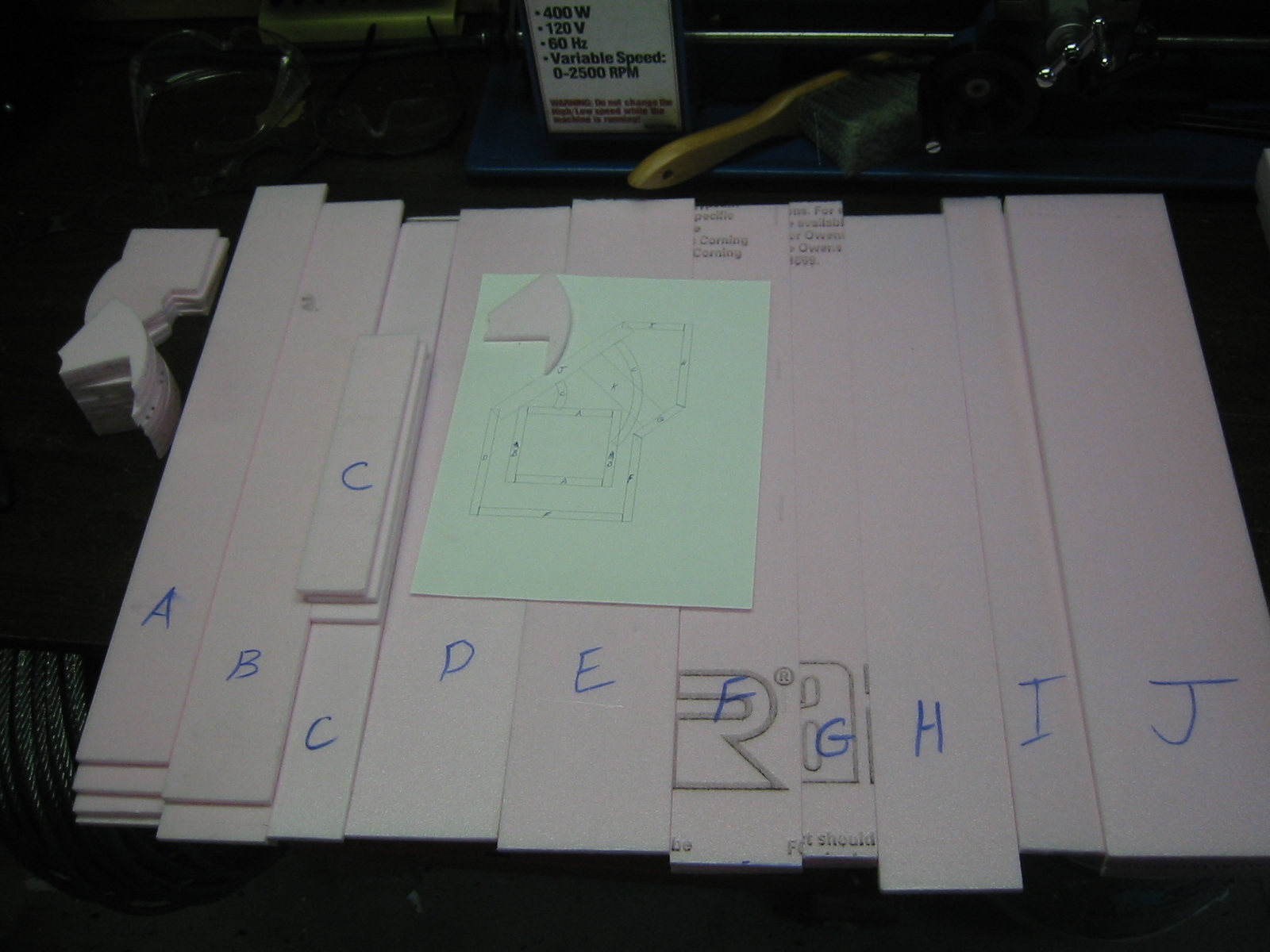

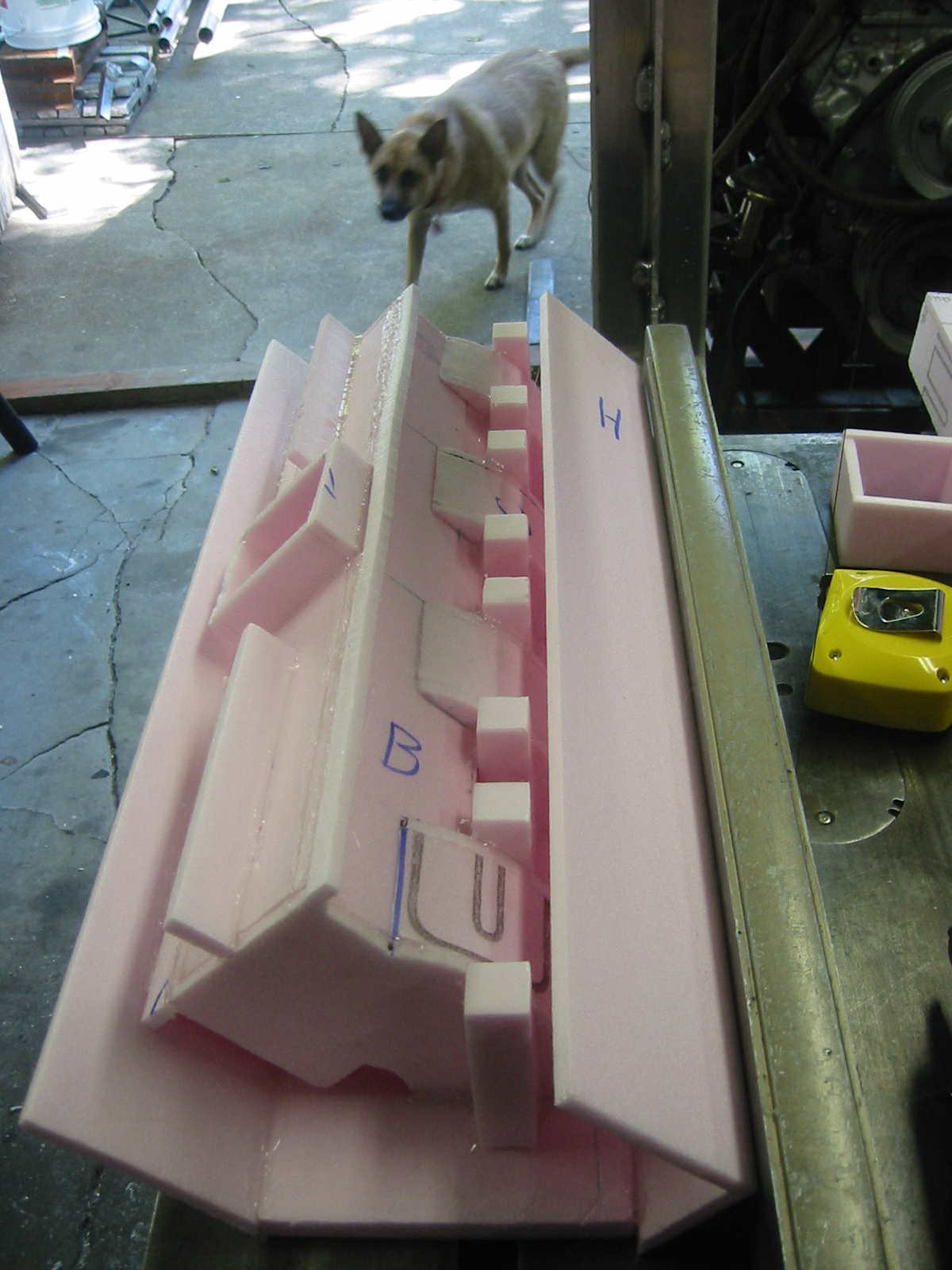

(2) Foam parts are glued together on the edges using hot glue.

(4) Parts are dipped in sheetrock mud investment, dried and then dipped again, until a thick layer of investment is built up.

(6) When the investment is 1/4 to 3/8 inch thick the vents are cut open and the the foam is dissolved with acetone.

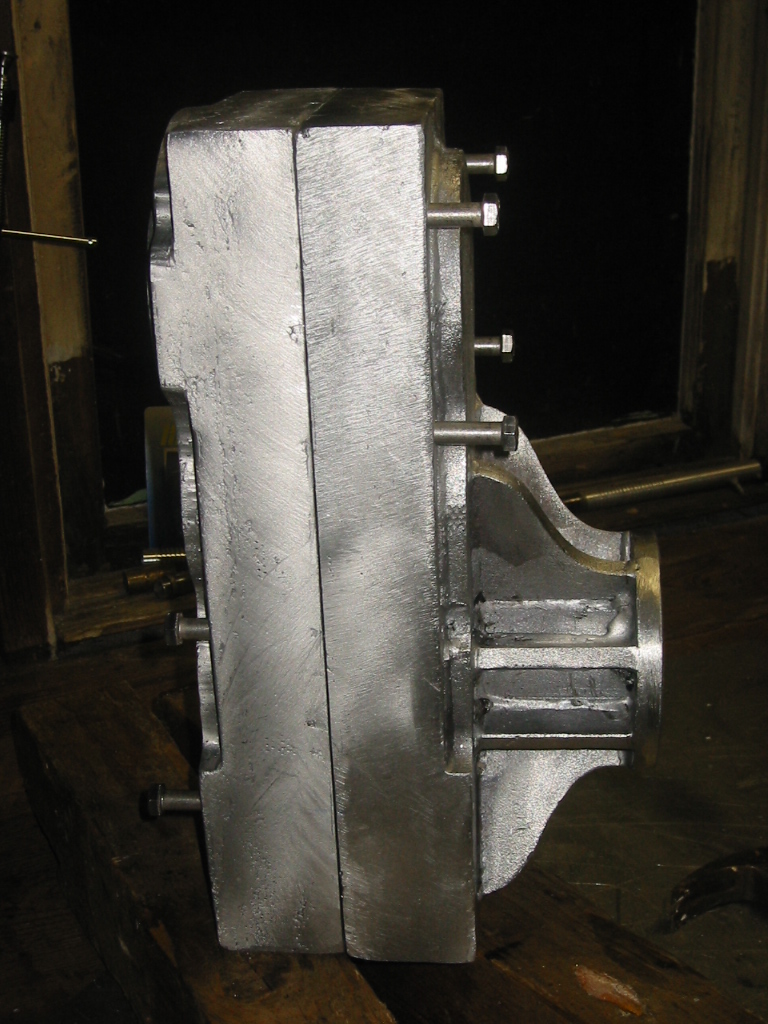

(8) Gearbox halves after the mud was removed by letting them soak in a bath of water.

(10) Gentling grinding down any high spot on the mating surfaces.

(12) Trail fitting the bearings into the jig

(14) Completed gearbox with the drive shafts, bearings, and spur gears.

(1) Needing to recover from the disastrous use of plaster/silica investment. I’ve turned again to the proven ready-mix sheetrock mud investment method in order to cast a gearbox.

(2) Again the foam gearbox part is build up from smaller foam parts and glued together with hot glue. Be sure to only glue the edges. If a solid layer of hot glue is used to join two parts, it will prevent acetone from flowing thought the part and dissolving all of the foam, and any remaining foam remaining in tact will expand when heated and shatter the mold.

(3) Once the two halves of the gear box were ready, then were joined together with small dabs of hot glue and then dipped a few times in order to insure that the two halves were square to each other. Unfortunately I used too many dabs and did a poor job cutting then apart which seriously damaged the edge. To make a repair I built the edge back up with wax. Notice that I also added a small brace to the vent, which did a nice job of preventing it from breaking off during the week of dipping and drying. No more fishing broken vents out of the mud vat and gluing them back on.

(4) The parts are allowed to dry between each dip in the mud. I have a 25 gallon plastic storage container filled to the brim with one part ready mix mud and one part water. My dryers are an electric meat smoker which adds a nice hickory sent to the shop and a stack of fire bricks that get rearranged to fit the size of the part as needed. This is heated with a heat lamp or an $10 electric coil originally intended to light charcoal briquettes.

(6) Once there is a 3/8 inch layer or more of mud the pouring spout and vent are cut open using a hack saw, hand saw, or reciprocating saw. The reciprocating saw makes quick work of it but be sure the mud is thick and dried hard so that it can take the stress.

Next a couple of cups of acetone will melt the foam into a chewing gum like residue inside the part. Actually the polystyrene is completely dissolved by the acetone, but the foam contains other ingredients like plastic and contaminants that are not dissolved. With the foam out of the way, the part can now dry from the inside and it needs to be dried thoroughly. Acetone is very flammable and the fumes are explosive so do not put the part directly into a gas oven!

(7) With the foam gone there is no danger of the foam expanding and breaking the mud, and the parts can be placed into the furnace in order to burn out the foam residue. This took about 2 hours at 900 degrees for the gear box parts. Not all of the residue was removed but what remains should not cause too much burn off during the pour.

(8) Each half was poured separately. There is about 10 pounds in the larger part. Sections of the part are more than 1 inch thick. There was some cracking of the mold, but the sand surrounding the mold did a fairly good job of containing the aluminum. The mold was in perfect shape before the pour but the part was cold and I think the cracking could be minimized if I were able burn out the foam residue and the pour the mold while it is still hot.

(9) Trimming the mating edges so they fit flush together started on the table saw. I clamped a 90 degree brace to hold the part vertical and a piece of aluminum between bottom edge of the part and the table saw’s fence provided a straight pass. (10) This was followed by lots of delicate grinding after a piece of paper was slipped between the two halves in order to find and mark high spots.

Next, 3 – 3/16 inch stainless steel pins were tapped into the halves to assure the halves always had the same alignment when placed together and then holes were drilled and tapped for 8 -3/8 inch stainless steel bolts that will hold the two halves to together.

(11) (12) Finally the recesses were cut for the bearings using a router and jig. A mill would be the the best tool for this task, but I don’t have one, so I turned a circle on my lathe and then welded that to a plate that I could position and bolt to the box. This required ordering a couple of extra long straight router bits from www.toolbarn.com. The first bearing was allied with the drive shaft from the Berkeley Jet Pump. Then using a paper template printed from CAD a second jig was built to alien the other bearings from the first recess.

I made a couple of the recesses a bit too large, but metal epoxy works nicely to fill these in. After 24 hours, metal epoxy can be machined just like aluminum. It holds up nicely to 350 degree heat and 2500 PSI pressure but is susceptible to shock stress.

After destroying one router and bit when the router got away from me, I decided to slow the router speed down by powering it though a common dimmer switch. Actually this is the same dimmer switch I use with my hot wire cutter. The results were excellent! The dimmer switch allows the router to run at less that half its normal speed, making it much easier to do fine work. With the slower speed, I could use the router free hand in order to shave the recesses for the bearings until I eliminated any binding once the gears were assembled.

Casting Wet Manifolds — another failure.

Round Two of trying to cast wet manifolds for the diesel engine. After many nights the cutting and gluing I once again have a set of foam manifolds to start coating with mud. After breaking off the vents a couple of times during the mud dipping process I decided to reinforce those parts with Plaster of Paris.

Foam sliced to size.

Gluing up the inner box.

Drilling holes for the exhaust.

Testing the fit.

Adding the water box.

Adding the sprues and vents.

After many coats of mud.

Placing in a pre-heat box.

Lots of steam and other bad omens during the pour.

The hideous results of water trapped in layers of mud.

Having spent a couple of weeks getting the foam to the point where I though it was ready to cast, I decided to build a pre-heating box. The pre-heat box is built for thin steel sheet and designed to incase the mold in sand. A steel lid is cut and welded into place and sealed with plaster to hold the sand inside, while exposing the spure and vents. The box has pipes welded onto each end that allow the entire box to be rotated upside down. Once up side down the box was then enclosed inside a fire brick box whit a steel lid and the temperature with brought up to 700 degrees over 4 hours. The idea was to burnout the foam, then rotate the box upright and immediately pour the aluminum in order to reduce the thermal shock to the mold.

Unfortunately that was not what happen. After 4 hours it was apparent that the foam was not burning out because I did not get the smoke normally associated with this process. My guess is that the sand surrounding the mold was acting as insulation and

preventing the inside of the mold from getting hot enought to burn out the foam. With a crucible now brim full of molten aluminum I decided to press forward with the pour. I removed some of the fire bricks and rotated the box into position for the pour. As soon as the molten aluminum hit the mold, smoke and steam shot from the two vents. The smoke was expected, but the steam was not. Even after emptying all 15 pounds of aluminum into the mold, it was still not full, which was another very bad sign. The end product was a horrible casting with large voids and aluminum in several places where it should not have been. In stead of trying to cast the second manifold I decided to dissect it. What I found was that the internal parts of the mold had dry surfaces but hid large amounts of very wet mud underneath. I had taken 2 weeks to dip the manifolds once a day and then allow them to dry in a 100 degree oven, but even that was far too fast.

I learned some good lessons with this attempt but having spend the better part of 2 months trying to cast manifolds I am ready to try a different approach to the problem. So for now I am setting such an ambitious cast aside and I will take a stab an cutting and welding a manifold together.

Read about the successful approach to building a manifold here: Wet Manifold

Lost Foam Casting in Sand

This is a method that came to me from Master Ken, my casting mentor. (1) I needed a small box that I could make into a waterproof switch enclosure, so I cut and glued some foam together then packed it into a flask of Petro-Bond sand. Regular sand would work too but Petro-Bond better fills in around the part and produces a much smoother surface and is much more likely to hold its shape. Used and burned Petro-Bond works too. There is no waiting on mud to dry, no need to dissolve the foam with acetone, and no vents are needed because the gas will pass into the sand. The resulting surface is rougher that using mud, but still good and very fast.

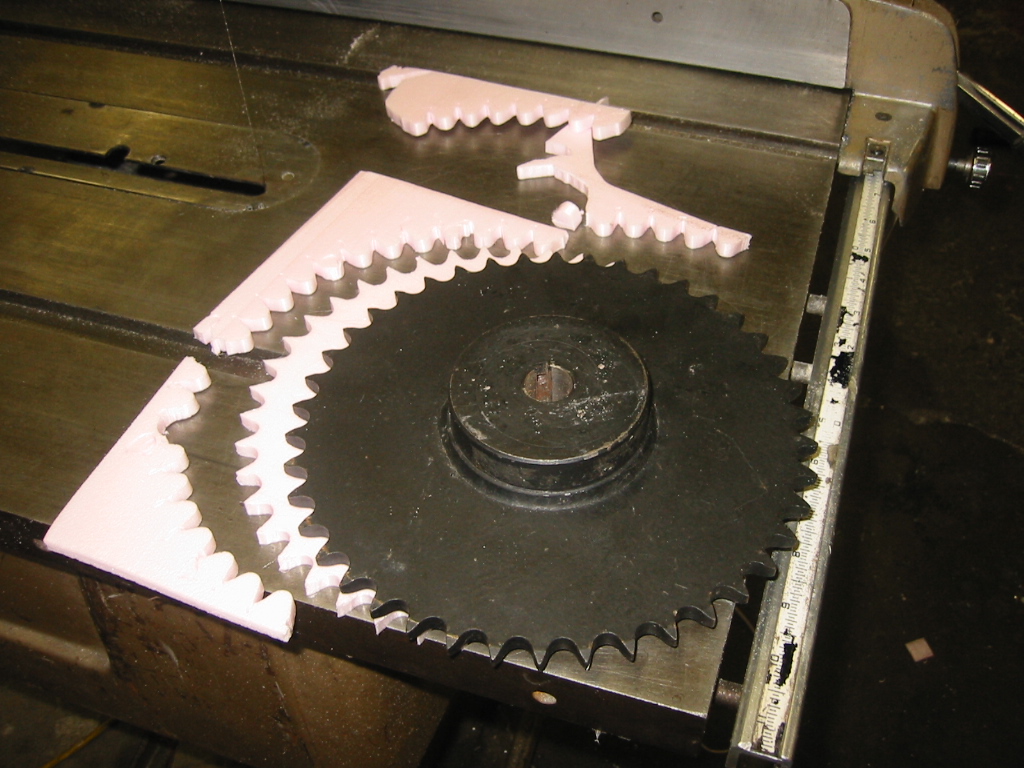

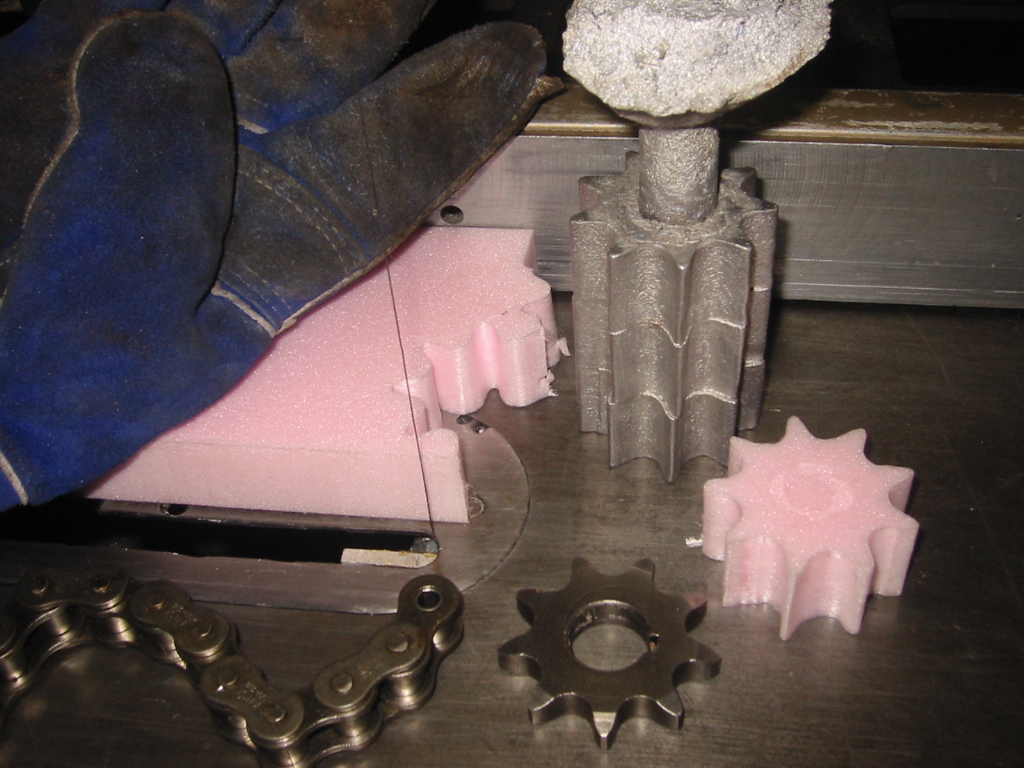

(2) I got to wondering if the higher density insulation foam; the pink stuff, would work? As it turn out, I was back to wanting to test some aluminum chain sprockets for a fairly low tork job. I used the one steel sprocket I had for a pattern and cut some copies out of 1 inch thick foam board. I hot glued a few of pieces together packed them into a flask of Petro-Bond, adding a 1/2 in diameter sprue through which to pour the aluminum.

(1) Cast switch box.

(3) Large foam sprocket part again using a real sprocket as a guide.

(5) Aluminum is the poured in and that burns out the foam.

(7) Completed test parts.

(2) Foam sprockets cut using a real sprocket as a guide.

(4) Spur added to the foam part and then it is buried in Petro-Bond.

(6) The part is allowed to cool for several minutes and the lifted out of the sand.

When poured it burst into flames as expected but much to my surprise there was no violent build up of gas pressure and no spitting the aluminum back out the sprue. Without a hard plaster or mud shell the pressure was obviously defusing into the sand.

The results were fantastic! This is the kind of reliable fast part production I had been looking for. Once I had the bar stock, it is just a matter of slicing off the individual sprockets.

Obvious next step was to see if it would work with the large sprocket. If I were really talented I could cast the part by just using the Petro-Bond, but as it were I could never remove the part from the sand without messing up several of the teeth. This way I just made a foam sprocket, packed it into the sand and left it there.

I first rigged a tall fence to my hot wire cutter which is really my table saw with some minor conversions. You can see my hot wire cutter here: Hot Wire Cutter. With this I can slice a 10 inch wide sheet of foam so that it is 1/4 inch thick.

(3) I then use a few dabs of hot glue to secure my steel sprocket to the piece of foam I carefully used it as a pattern for cutting the foam is the hot wire. It is important to keep the wire as cool and possible and not to pause while making a cut against the pattern. This keeps the cutting line as thin and smooth as possible.

(4) Once the foam is cut out, it is freed from the steel pattern and a 1 inch spur is glued on. A layer of Petro-Bond is then placed in the bottom of a flask and the steel sprocket is hammer down into the sand to ensure that sand is level. Baking Soda dusted onto the steel will ensure that the sand does not stick to it. Once the sand is ready the steel sprocket is removed and the foam sprocket takes its place. More Petro-Bond fills the flask but only 1/2 of a flask is used, so it is only 3 1/2 inches high. And any sturdy heat resistant container would work. There is no need to use a flask.

(5) Using the flower pot furnace to melt the aluminum I was able to cast five sprockets in an afternoon, and four of them were good. One failed to completely form likely because the aluminum was not hot enough. I used both fresh Petro-Bond and the old burned stuff. Both worked equally well.

(6) When using Petro-Bond, I separate the burned sand out an keep in a separate bucket. Before using it again it only needs to be riddled to break up the clumps. A riddle is nothing more than a piece of metal window screen or a sifter from the kitchen. Burned Petro-Bond is fine for this type of casting since it does not have to maintain its shape, while a part is removed.

(7) I turned out not using the completed parts, but it was sure nice to have them for testing after just one evenings work.