I can’t wait for the oil wells to run dry, for the last gob of black, sticky muck to come oozing out of some remote well. Then the glory of sail will return.Triston Jones

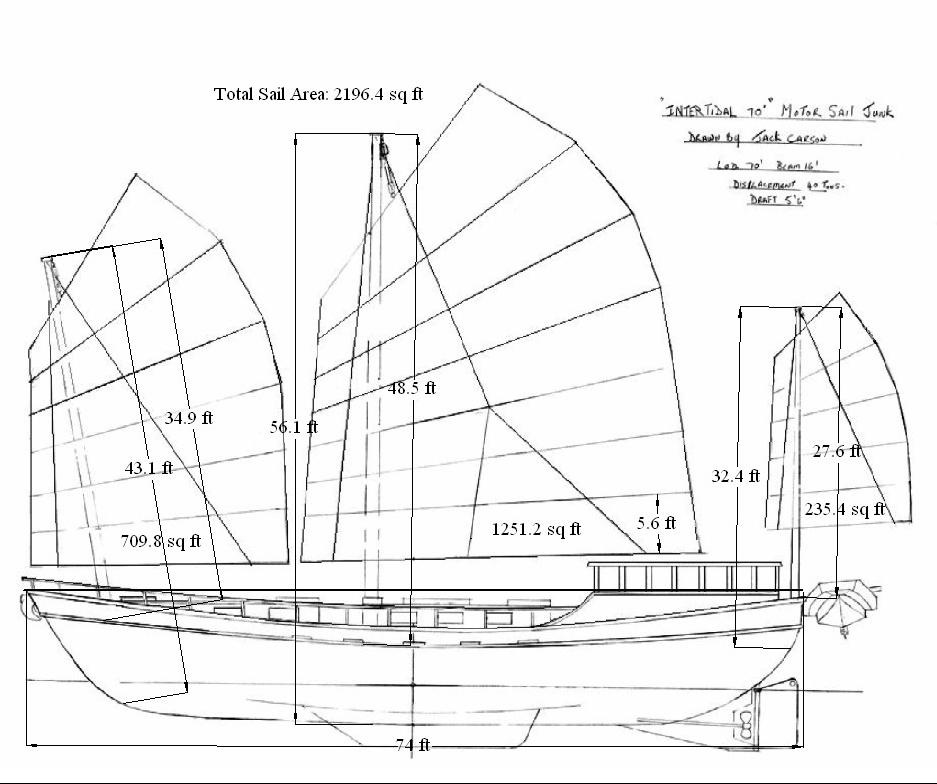

We did not fall in love with sailing or a particular type of sailboat. Instead we wanted to explor, work, dive, salvage, charter, operat an ROV, and build things. We did not want to cruise from one bar to the next. So we sized the boat to fit the job, then we needed sails that one person could manage. After sailing on a bermuda rigged boat, and watching a big gaff rig go up, we got on a junk rigged boat and saw for ourselves how incredibly easy these sails are to raise, lower and especially reef. So now we love junk sails. Seeker will have about 2,200 square feet of sail. She will need more than 5 knots of wind before she will sail, but she’ll be able to make about 9 knots in a good wind.

Criteria for the Mast

A 1251 sq ft sail in a 35 knot (40 mph) gust from a passing squall will sustain a 8,626 pounds of load. At 61 knots (70 mph) that goes to just over 20,000 pounds. With a center of effort about 20ft up the mast from the partners that spread the loads to the hull. A light weight boat would simply be healed over or knocked down so that the force of the wind is spilled from the sail. But Seeker is more elephant than gazelle. Fully loaded she is 40 tons, with 15 tons of lead ballast and a 16 foot beam. She will not heal easily so the rig must be stouter than most so that something horrible does not happen.

#1 Strength – We have 3 masts and what we expect to be a very stiff boat when loaded so I don’t see quick healing spilling load from the sails. Hence I have used the strongest recommendations I could find, which were in “Design and Build Your Own Junk Rig”.

#2 Cost – We are a work boat, and not a charter cruise boat so it does not have to be pretty.

#3 Speed of Construction – Laminating a mast from strips of wood is right out. Tapering a steel pipe does not look that bad, but an off-the-truck galvanized and ready to install mast would be great.

#4 Weight – I know there are some good arguments for heavy mast and longer roll intervals, especially when it’s a junk rig anyway. But I’m having problems getting past how counter intuitive that sounds. 🙂 Jay Jeffries who is studying to become a naval architect contributed to following: “It is an inertia issue, you don’t need a lot of weight for this as it is a long distance from your center of rotation. Here is my submitted answer for the issue: A dismasted sailboat is more vulnerable to capsize as compared to a vessel with an intact mask due to the large inherent roll inertia (i.e. resistance to rolling motion) of the mast and rigging. It is estimated that the mast and rigging contribute 60% of the total roll inertia when compared to the other two major weight contributors to a boat: hull and ballast. While the mast’s and rigging’s combined weight is much less than the other two, it’s gyradius (k, also known as radius of gyration) as measured from the vessel’s CG is much greater. The moment of inertia (Ir) is defined by the calculation: Note that the distance of the center of mass of the mast and rigging from vessel’s CG as defined by k is squared which greatly increases the resistance to roll.

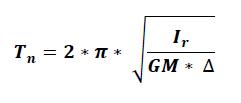

A longer natural period of roll (Tn) for a boat is desirable to avoid resonant magnification between the wave trains and the hull. As found in the following equation, a larger Ir will contribute to a larger natural period of roll for the boat.where:

Tn = the vessel’s natural period of roll

Ir = vessel’s moment of inertia

GM = vessel’s metacentric height

∆ = vessel’s mass displacement”

You can download this here: Mast_and_roll_inertia.pdf

#5 Hollow Mast – We want the mast hollow and open for wiring, possibly the engine exhaust and ventilation so having it hot dipped galvanized seems like the best way to protect the inside surface.

Following the formula in “Design and Build Your Own Junk Rig” we get the following:

A=sq ft of sail area

H = height of mast above the partners (supports) in inches.

S = safety multiplier (2 for small ballasted, 3 for large, 3.5 for beamy boats or boats over 35 ft.

Diameter in Inches = Cube Root of (16 x A x H x S / 15700). Our numbers for the main mast are: A = 1252, H = 542, S = 3.5 Or the cube root of 38000704 / 15700, or the cube root of 2420.4270063694267515923566878981 which comes out to: 13.426536495548100264179437252339. Did it all in my head. 😉

So we need a main mast that is about 14 inches at the partners; it’s total length is 56.25 ft the mast above the partners is 45 ft and 11.25 ft extends down to the keel. The mast is tapered so that the top of the mast is 7 inches or 1/2 of the diameter that it is at the partners. The thickness of the steel is 3/8 inch for 50 ft or more, 1/4 inch for 30 to 40 ft, and 3/16 to 1/4 for 20 feet, so our main mast will be 3/8 inch.

Main Mast

Sail Area

1,252 sq feet

Length Overall

56 feet

LAP (Length Above Partners)

45 feet (540)

Bury (Total Length – LAP)

11 + feet

The minimum is .15 x mast length or about 8.5 ft in our case.

Diameter Partners

13.43 inches

Diameter Top

7 inches

Ratio for the taper is 7 inches over 45ft, or 7/45 = .15555 in/ft

Diameter Base

15.71 inches

Ratio of taper .15555 in/ft x 11ft + 14 in

Wall Thickness

3/8 inch

Actual Diameter at Partners

14 inches

Schedule

30 Std

Weight per Foot

54.57 lbs

Straight Pipe

Weight above Partners

1,841.7 lbs

Straight Pipe – No Taper

Weight below the Partners

600.3 lbs

Straight Pipe – No Taper 54.57 x 11 ft = 600.27

Total Weight

Forward Mast

2,442 lbs

Sail Area

710 sq feet

Length Overall

43.5 feet

LAP (Length Above Partners)

35.5 feet (426 inches)

Bury (Total Length – LAP)

7.9 feet (95 inches)

.15 x 36 ft = 5.4 ft min bury

Diameter Top

5.128 inches

Diameter Base

11.39 inches

Wall Thickness

Mizzen Mast

1.4 inch

Sail Area

236 sq feet

Length Overall

32.33 feet

LAP (Length Above Partners)

28 feet (337 inches)

Bury (Total Length – LAP)

4.33 feet (52 inches)

15 x 28 ft = 4.2 ft min bury

Diameter Partners

6.57 inches

Diameter Top

3.3 inches

Diameter Base

7 inches

Wall Thickness

1/4 inch

8-sided Steel Mast

Just a mile down the street from us is a Valmont manufacturing site that make 8 and 12 sided steel galvanized utility poles to order. We put on nicer clothes (to look more respectable) and walked in the front door with our mast specs. After a few “you’re stupid looks” we got Tom, the utility department manager and convinced him we were for real. Unfortunately their press is only able to form 8 sided poles when the top is less than 10 inches, however the price is better than I expected. Below is the quote from Tom Lovegrove.

JOB: QR18235-09 DATE: May 21, 2009

CUSTOMER: Jackson Boat Builders

PROJECT:

COMMENTS:

ITEM QTY DESCRIPTION WT EA. $ EA. GALV Price $ TOTAL

1 – 56′ ft, 8 sided Pole, 2665 lbs, $2,507 $710 $3,217

15.71″ Bottom diameter, 7″ top diameter

1 – 43.4′ ft, 8 sided Pole 992 $1,098 $264 $1,362

10.25″ Bottom diameter, 6″ Top diameter

1 – 32.33′ ft, 8 sided Pole 585 $840 $156 $996

7″ Bottom diameter, 6″ Top diameter

TOTALS: $5,575

* Pricing is FOB Tulsa Plant

* Poles to ship eight (8) weeks after reciept of Purchase Order

*Shaft material is ASTM A36 grade

DIY Mast

We can get 2 – 30ft sections of 16″ Sch 30 steel pipe for 1500, pluss 200 for delivery. It’s interesting how much the diameter does for the strength, and a 14″ Sch 30 pipe actually weighs more but is not as strong.

16″ Sch 30, .375 wall, 62.58 lbs/ft, Midpoint deflection on 360 inches (30ft) of 9.22282″ with 5 tons $25.00/ft 1,500+ 200 delivery

16″ Sch 20. .312 wall, 52.36 ;bs/ft Midpoint deflection on 360 inches (30ft) of 10.9541″ with 5 tons

14″ Sch 30, .375 wall, 54.57 lbs/ft, Midpoint deflection on 360 inches (30ft) of 13.9071″ with 5 tons

14″ Sch 40, .437 wall, 63.37 lbs/ft, Midpoint deflection on 360 inches (30ft) of 12.0950″ with 5 tons

16″ Sch 20, .312 wall, 59.03 lbs/ft, Midpoint deflection on 360 inches (30ft) of 10.9541″ with 5 tons

16″ Sch 10, .25 wall, 47.39/lbs/ft. Midpoint deflection on 360 inches (30ft) of 13.5118″ with 5 tons

Ref: http://www.engineering.com/calculators/beams.htm#tube

http://www.allsteelpipe.com/Pipe-Dimensions-Weights-Chart.pdf

Steel Mast Example from “La Chica”

Main Mast

LAP: 10,460mm (34′ 4″)

Bury: 2,240mm (7′ 4″)

Dia Partners: 235mm (9 1/4″)

Dia Top: 96mm (3 3/4″)

Dia Base 117mm (4 5/8″)

Wall is 3mm (.118″ < 1/8") thick except for first section which is 4mm (.158" < 3/16")

Sail Area: 37.35M Sq. (402 Sq.Ft)

Weight of Mast - LAP = 136kg (300 lb)

Bury = 30kg (66 lb)

Total = 166kg (366 lb)

Just for comparison the "Practical Junk Rig" (PJR) book states that a solid wood mast with 402 sq ft and 34' 4" LAP would be 10" 3/8 diameter main. La Chica's mast is 9 1/4" diameter. Some have the opinion the PJR specifies mast that are too heavy.

Fore Mast

LAP: 8,745mm (28' 7")

Bury: 1,165mm (3' 9")

Length of mast: 9,910mm (32' 6")

Dia Partners: 195mm (7 5/8")

Dia Top: 80mm (3 1/8")

Dia Base 95mm (3 3/4")

Wall is 3mm (.118" < 1/8") thick except for first section which is 4mm (.158" < 3/16")

Sail Area: 24.81M Sq. (267 Sq.Ft )

Weight of Mast - LAP = 94kg (207 lbs)

Bury = 13.5kg (30 lbs)

Total = 107.5kg (237 lbs)

PJR recommends a solid wood mast at 9 3/4" compared to La Chica's 7 5/8" steel mast.

"The mast are 16 sided and made up of 3.6M (0.142" < 3/16") sections which were bent up in a brake for me by local company (New Zealand) called CSP. The sections were computer welded up one side. Where the sections join, a sleeve has been inserted. The sleeve was first puddle welded to each section and the the seam fully welded up by hand."

"I made the first section for each mast from 4mm stock. This was no so much for strength as for toughness as 3mm steel is actually quite thin and if a hollow section is dented, it looses quite a bit of strength. After being made up the whole mast was hot dipped galvanised. They will be epoxy coated as well and finished with two part polyurethane before I step them on La Chica. Hopefully that will be this year." --Regards, Paul Thompson -- www.sailingwithoutasound.com

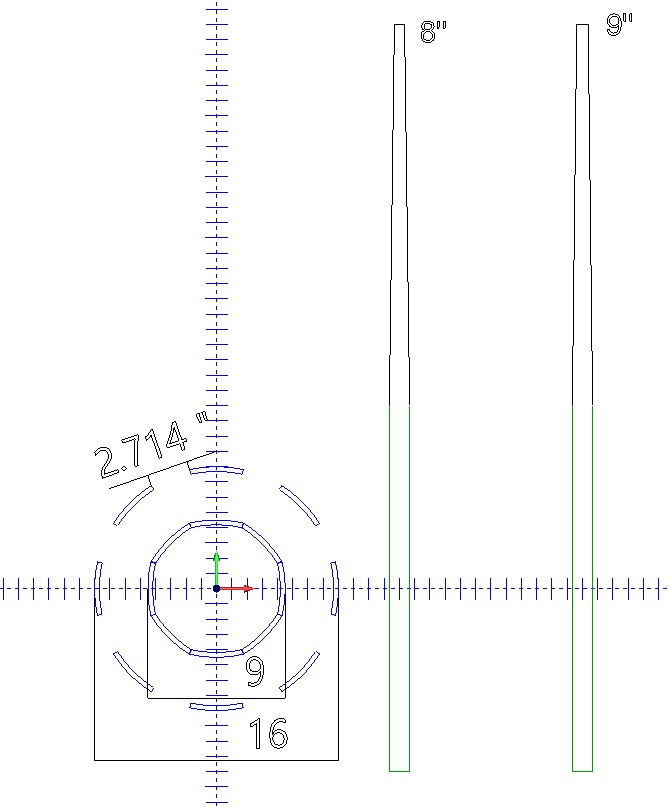

I’ve decided that a 9 inch top looks better than an 8 inch too. And after a little math that we need to cut out wedges that are 2 3/4″ wide at the top and taper to zero 25 feet from the top.

I’ve decided that a 9 inch top looks better than an 8 inch too. And after a little math that we need to cut out wedges that are 2 3/4″ wide at the top and taper to zero 25 feet from the top.

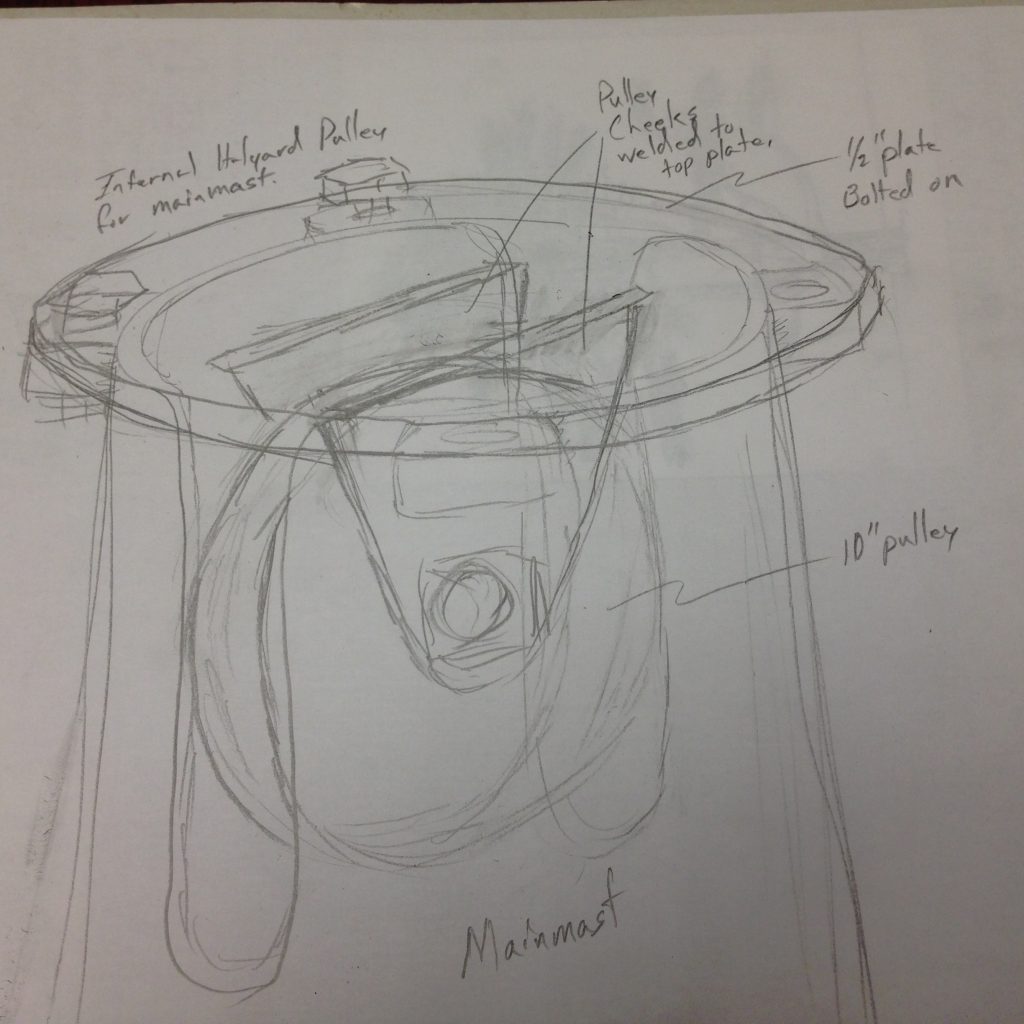

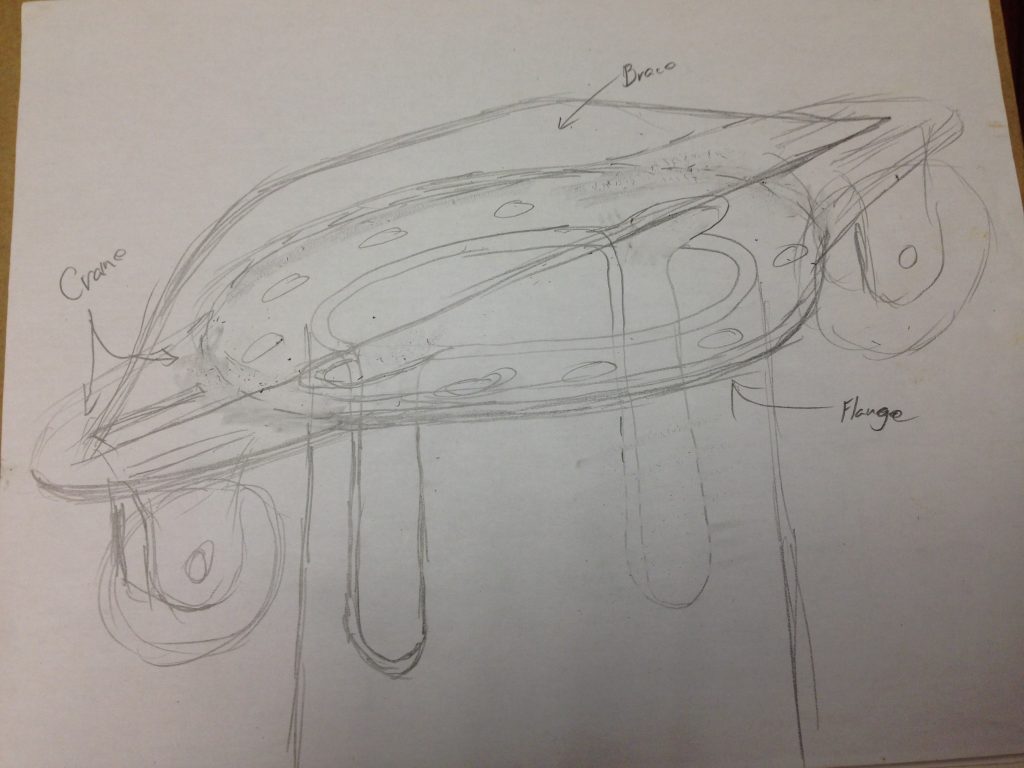

Another thing I like about a bolt on masthead is that we can easily change the design to a crane with two pulleys instead of a single internal pulley. And any other crip-crap can be welded or bolted on with the top down in the machine room and not while swinging from the mast.

The main mast reaches some 52 feet off the water provided the boat drafts 6 feet. The problem is that there are two bridges on the water way that make that draft imperative or else we will have to list the boat or build the mast with are removable top section.

The I-430 bridge over Murray Lake just before Little Rock, Arkansas is 52.4 feet, and the Benzal Railroad Drawbridge just before the Mississippi Rivver is only 52 feet.

I-430 https://www.google.com/maps/@34.8006859,-92.3731758,1521m/data=!3m1!1e3

http://www.swt.usace.army.mil/Portals/41/docs/missions/navigation/charts/chart54.pdf

Benzal Railroad Drawbridge https://www.google.com/maps/@33.9992319,-91.1595568,199m/data=!3m1!1e3

http://www.swt.usace.army.mil/Portals/41/docs/missions/navigation/charts/chart73.pdf

Hence we have to decide about listing the boat or building the mast so that the top few feet can be removed.

Solid Wood Mast

Wood vs Steel; U.S. – Douglas Fir’s strength is 7,000 psi. Locally available pines may be as little as 5,000 psi. A steel main mast will need to be 14 inches in diameter and 1/8 or possibly 3/16 inch wall.

Douglas Fir doesn’t grow in Oklahoma, or anywhere near for that matter. But a fir pole for the main mast can be purchased for about $3,500 including shipping from www.americanpoleandtimber.com. A galvanized steel 12 sided mast is about $2,500. Salvage yard steel will be about $1600 plus a lot of work. Steel is also more that 40% lighter than a solid wood mast. A 1,465 pound savings on the main mast. Other sources for wood poles can be found on www.sticktrade.com.

Fiberglass Mast

Armed with the specifications for a steel mast, I sent those to Rob at Architectural Lighting, an Oklahoma distributor for Shakespeare Composite Structures, to have them find an equivalent wound fiberglass. Rob: 918 584-5554 rob@okals.com

I got this reply back from Rob: “The regional sales manager just emailed me stating that Shakespeare does not manufacture poles for this application. Sorry.”

I just love it when some douche bag decides I cannot buy their product for my application.