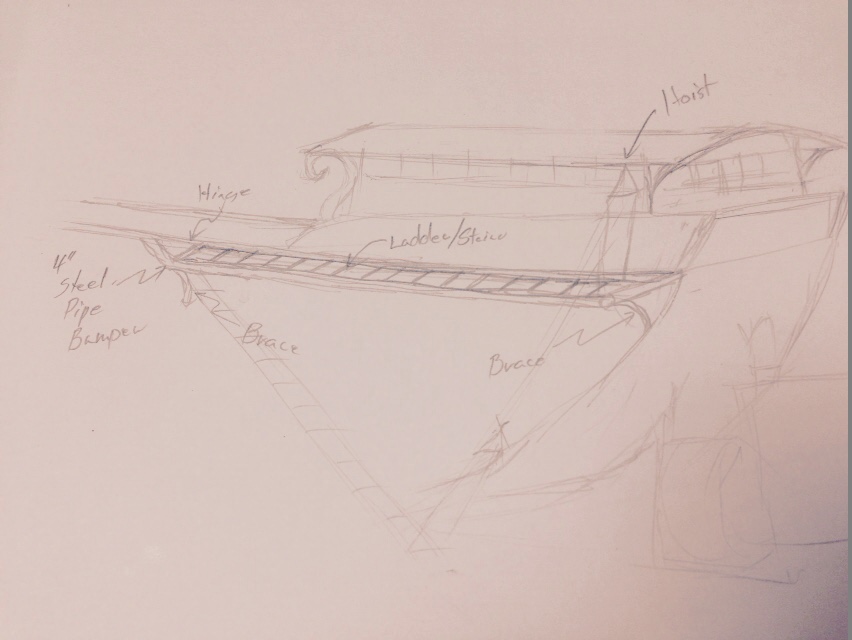

With the pilothouse the same width as the deck, there needs to be some way of getting back and forth down the side of the boat without passing through the pilothouse. You can imagine how inconvenient that would be for moving an anchor line. The Chinese faced a similar problem with they needed to pole their boats up river with the decks filled with cargo. The solution was to place temporary walkways or catwalks over the water and along boats deck.

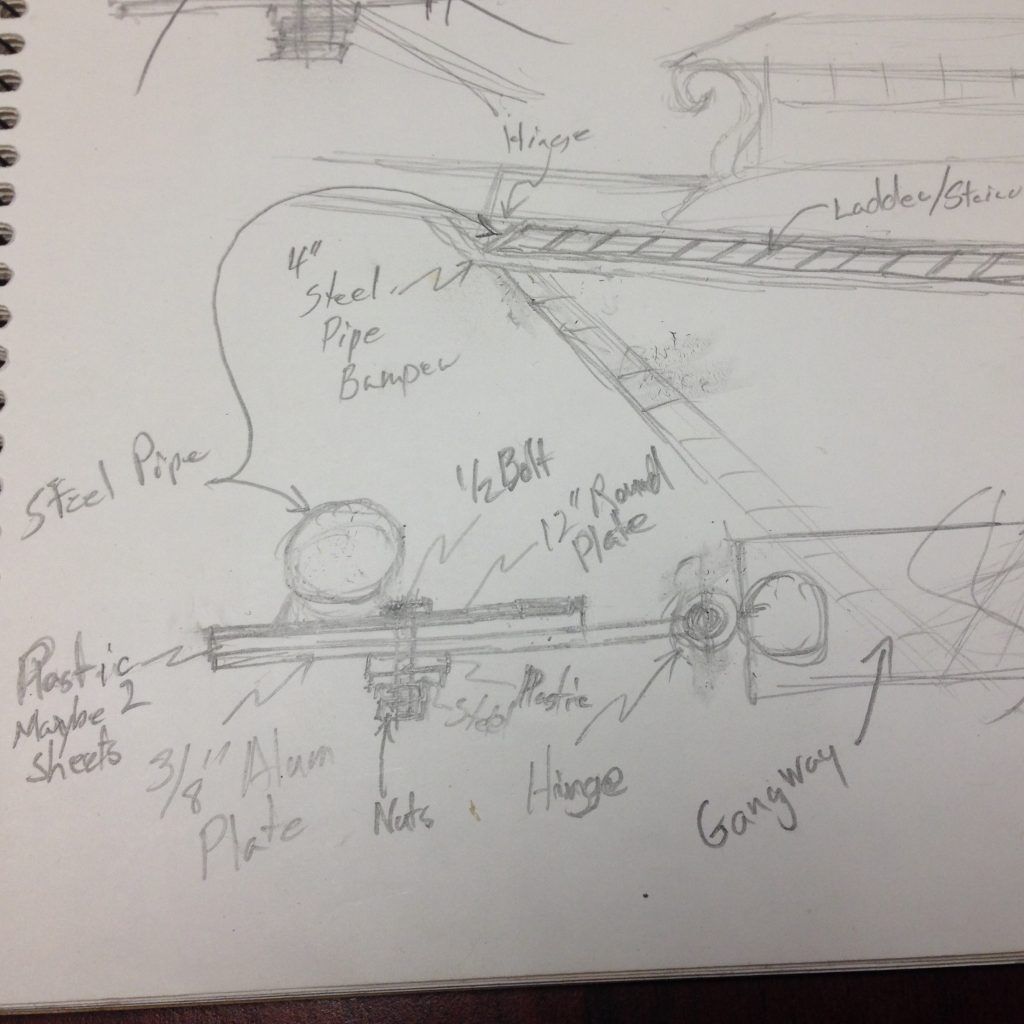

But we also need a gangway, and possibly a gang way they can lower and also be pitched out to the side and even raised about the deck, in case the dock is higher than the deck of the boat. A gangway can also be used to access the water or ground beneath the boat when Seeker is sitting on her keels in a tidal zone.

There will be no permanent deck on the structure as that would become a hazard in heavy seas. Instead the deck more likely be open. A round rung ladder may be best. However the structure needs to be strong enough that it can resist impact with a dock without damage. This will not only protect a light wight ladder but also the roof of the pilothouse which also overhangs the sides of the hull.

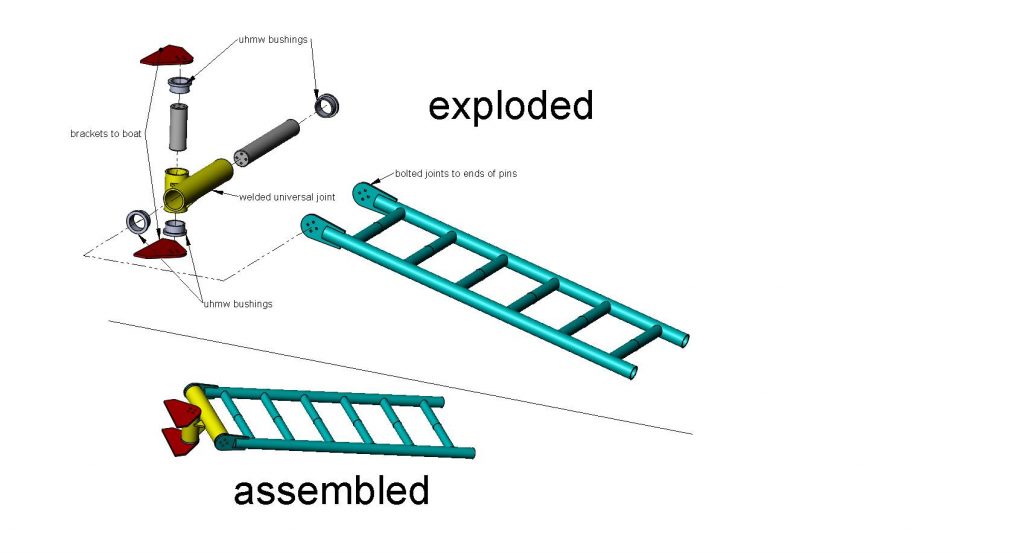

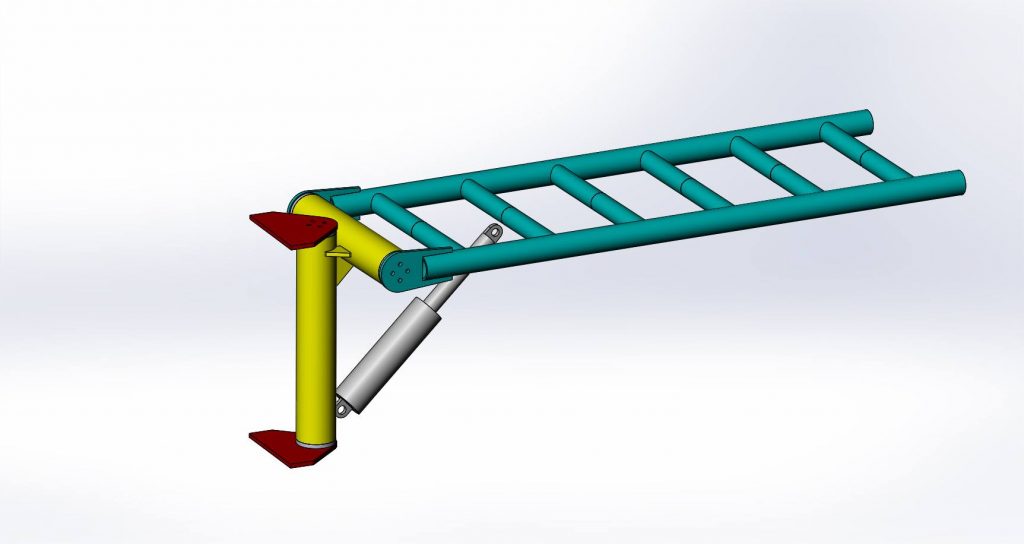

A commercial ladder is an option, but only if it is fiberglass. Neither wood or 6061 aluminum would hold up well to seawater. A 20′ All-Fiberglass Straight Ladder is about $800 each from Werner. We can also build one from 5086 aluminum pipe. We have redesigned the battens for the sails so it just happens that we have aluminum pipe available. This approach would also give us the ability to more easily modify the ladder for the task, such as adding holders for stays and a hand rail. If we built the ladder the goal would to have a stronger ladder that what it typically available commercially, which is to say it can support 400 pounds in the center when placed horizontally and supported only at each end. Raising and lowering the ladder could be done with a manual hoist however is a hydraulic winch or block and tackle were used then the ladder could be raised with along with a diver and equipment. As the structure will not frequently be raised and lowered then it could most likely be best powered by a capstan on the rear deck that is also tasked with handling anchors and the tender.

As for the stee l frame outside of the ladder it seems most obvious to construct it from the same 3 1/2″ steel pipe used on the bulwarks. It maybe prudent to stiffen this with a light wight truss framing between the steel bumper and the ladder in order to reinforce the steel pipe from lateral impacts.

l frame outside of the ladder it seems most obvious to construct it from the same 3 1/2″ steel pipe used on the bulwarks. It maybe prudent to stiffen this with a light wight truss framing between the steel bumper and the ladder in order to reinforce the steel pipe from lateral impacts.

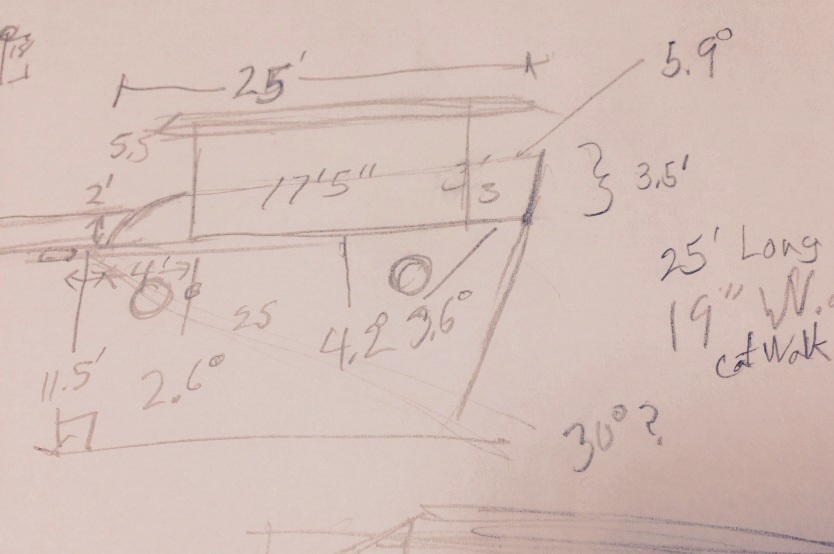

In order to minimize the slope of the gangway we can maximize the length to 25 feet. But that length will require a more robust frame than a typical ladder in order to minimize bounce when loaded with two crew and gear.

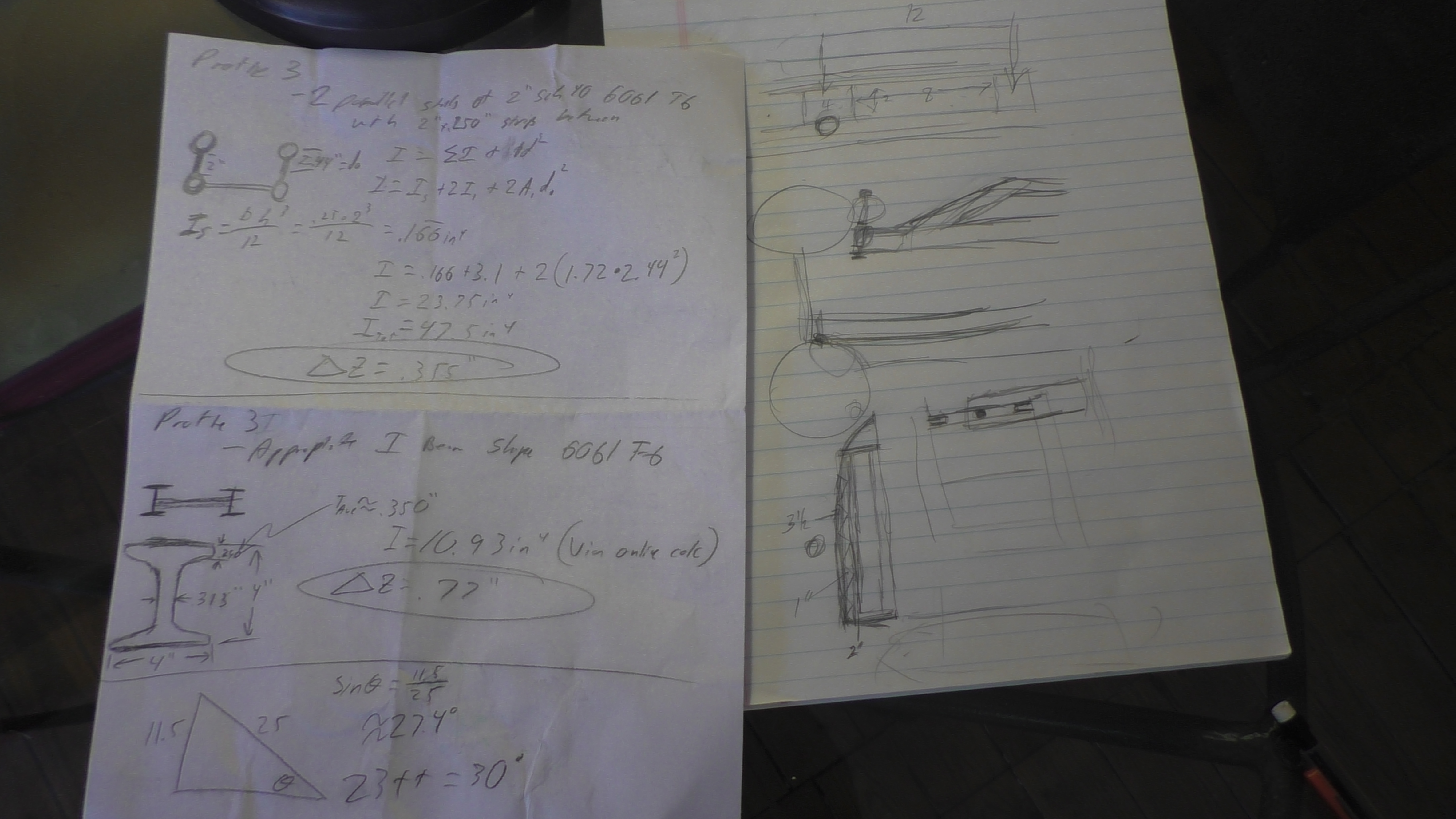

For most of the stuff I build, we bouncy up and down on the material and then decide how much we need to use, but Dan Germata and Megan Vinci stop in on their way home to Chicago and Dan did some math for us. If we build a 25 foot long gangway from 4 – 2 1/2″ Sch 40 aluminum pipes built into truss then we will be able to support over 3000 pounds without failing and it will deflect less than 3/8″ when you stand in the middle. It will only weighs about 250 pounds and floats! It makes for a rather large structure so we are going to only build one for the port side. The starboard side will only be a steel barrier  to protect the pilothouse as well as support a walkway that can be removed and stowed away on deck for bad weather.

to protect the pilothouse as well as support a walkway that can be removed and stowed away on deck for bad weather.

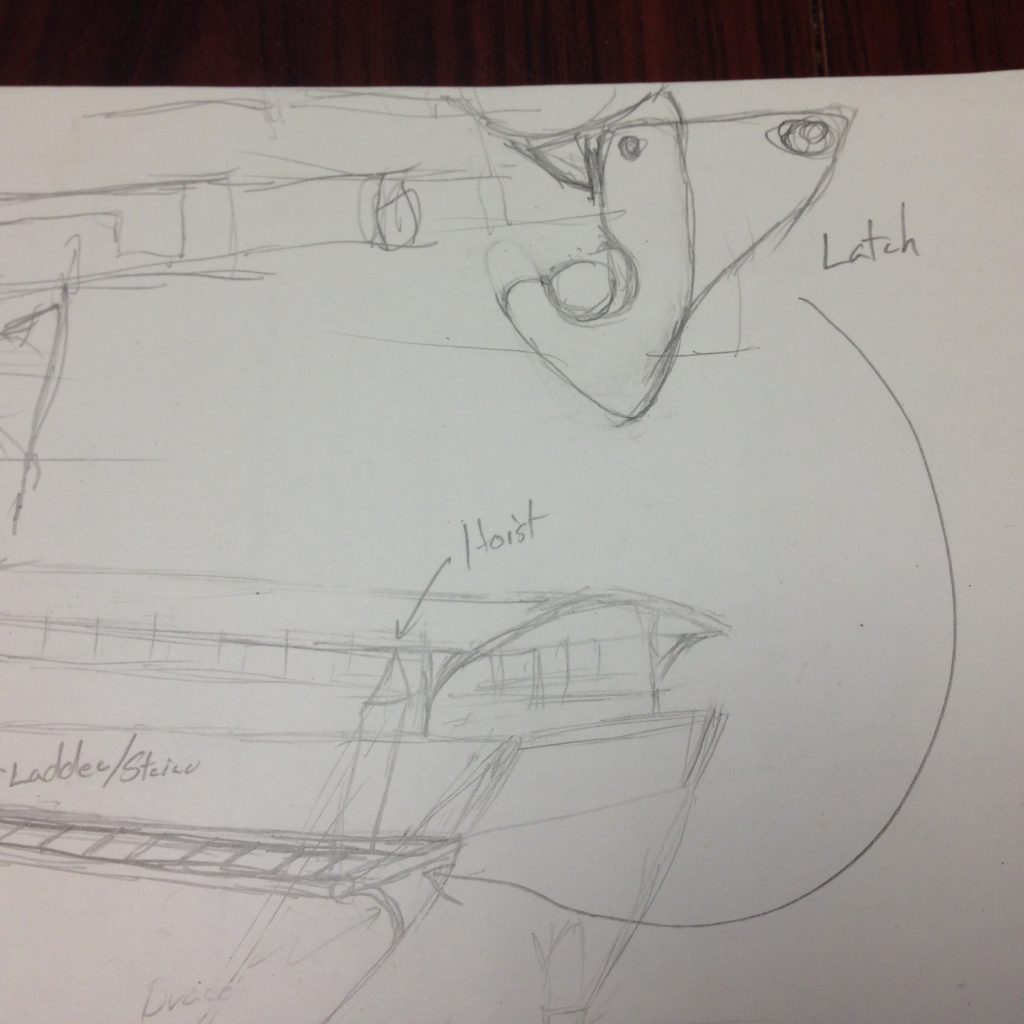

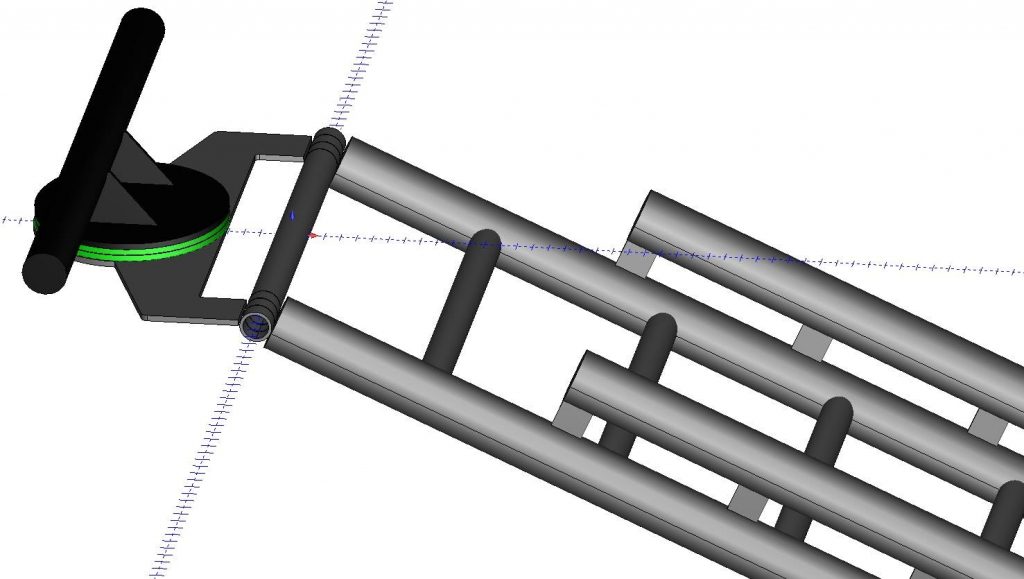

We worked up a design for the hing that we think will let us not just lower the gangway but also rotate it out to the side and in a complete 180 degree arc. And pin it into any position we like by dropping a pin through holes in the round plates. We will also make the hinge pin attached to the first step to be removable so we can quickly unpin the ladder from the mount and us it for some other purpose.

Ben Paske – “Not a huge fan of that one bolt. One bolt, one failure.” Offers what I think is a good design as well. My only reservation is it has more parts that need more machining.

I actually like the one bolt, one hinge pin design because we can easily release it from the boat and use it for other purposes. It is after all a sturdy 25 foot span.

9 Comments on “Gangways & Catwalks”

I am a little worried about the 3/8 aluminum plate, and all of your load will be under the plastic bearing plate and that poor half inch bolt could see a lot of tension if the gangway gets twisted. Maybe something like a 2 inch stainless SCH 80 pipe nipple instead of the 1/2 bolt. Then weld stainless pipe caps to two 12 inch round steel plates. One of the plates becomes what you have labeled as “12 round plate” in your drawing and the other becomes the nut on the bottom. Then you could sandwich the “3/8 alum plate” in the middle with bearing material above and below it. Then you would rotate the bottom cap/plate to tighten it all together to the right preload then drill/pin through the caps into the nipple to keep it secured.

Wait for it… 🙂

https://www.facebook.com/video.php?v=748750225255214

Hi Doug, I’ll need to draw this in order to explain better, but the top sketch may do for now… looking at the way the bulwarks rise toward the aft of the wheelhouse, you already have an old fashioned wooden ladder shape. ie Wider at one end and tapering.. You could make it match this to run directly along the existing pipes in the bulwarks so it integrates better alongside… maybe even curve it to match the bulwarks ? I dont see an option to attach an illustration, so I’ll send it to your ymail address as “gangway detail”. MIKE

Thanks Mike. I like that idea.

https://www.svseeker.com/wp-content/uploads/2015/11/Gangway-Detail.jpg

https://www.svseeker.com/wp-content/uploads/2015/11/Seeker_Gangway.jpg

I like the 3.5 pipe truss bumper/frame work, use a light weight wooden duck board walkway on top of the custom ladder that could be folded up and secured against the bulwarks in severe weather. In port your line handling is going to be done before you need a gangplank or ladder. the aft end of the ladder/walkway could be lowered and raised with a line off of the tender davit or pilot house roof overhang. if or when you need a true ladder to reach the ground or something taller the duck board walkway could be secured to the bulwarks and the ladder deployed either by hand or with the davit line at rear, or the mainsail boom, or the crane, or even by hand if the weight is reasonable.

I’ve never head the term “duck board” but google did the trick. I think something like that would be good. We could hook it onto the rungs and add strips for additional traction when the gang plank is lowered at an angle. I need to get some measurements to see how long and how steep we are talking about.

Closeup

I like that idea. I have seen it at the steel yard but I have not found any that I would want to walk on bare foot. It’s also very heavy. I was thinking that we might be able to find some in plastic and use that over the rungs of the ladder. At least down one side of the pilothouse in order to make it easier for those who are not accustomed to walking on ladders. But even that I think would have to be removed in heavy seas before the seas remove it.

Are you familiar with this type of catwalk?