Electric power for the various systems I wanted on Seeker was mistakenly high on my list of things to acquire when we decided to build. I soon learned that it rightly deserves a place at the bottom of the list. The technology is constantly improving and the prices for existing technology is constantly falling. If you are patient, you will either own the best available technology or used equipment at a great value. Or as in our case become the beneficiaries of generosity from someone like Ron Buttke of Wisconsin who donated a literal ton of off-grid power equipment. So now we need to learn everything we can about nickel iron batteries, inverters, charge controllers, and sundries.

There are 57 Nickel Iron batteries made in Hungry by AXi

Accusealed

From: www.homepower.com Battery Chemistry

Nickel-Iron Batteries

Nickel-iron (NiFe) battery technology was introduced around 1900 by Thomas Edison, so is referred to as the “Edison cell.” These batteries were originally intended to power electric vehicles but were also used for backup power for mining and railroad operations.

In NiFe batteries, the cathode is nickel oxide hydroxide [NiO(OH)], and the anode is made of iron (Fe). The electrolyte is a solution of potassium hydroxide (KOH), a little lithium hydroxide (LiOH), and distilled water.

When discharging, the active material of the positive plate changes from nickel oxide hydroxide to Ni(OH)2, and the negative plate changes from Fe to ferrous hydroxide [Fe(OH)2], with two electrons being released at the anode and pulled in at the cathode via the external circuit for each reaction. The electrolyte is only used as a medium for the hydroxide (OH-) ions to flow through.

The process is reversed during charging. Electrons are pulled from the nickel hydroxide electrode and driven into the ferrous hydroxide electrode. The potassium hydroxide and lithium hydroxide are not reflected in the chemical equations because the electrolyte is only a catalyst and does not participate in a chemical change with the active materials during charging or discharging. Unlike an lead acid battery, then, the electrolyte’s specific gravity does not indicate the battery state of charge. Instead, SOC or State Of Charge is usually measured by voltage while the battery is at rest. The nominal battery voltage is 1.2 V per cell. Nickel-iron batteries do gas during the entire charge cycle, and must be adequately vented and routinely watered with distilled water.

NiFe Pros

- Long life (10,000+ cycles)

- Robust (can be overcharged and deeply discharged)

- Freeze-resistant, even if discharged

- Large acceptable operating temperature range (approximately -20°F to 190°F)

- Best in systems with daily discharge/charge (not floating)

- They can be stored for ages in a discharged state.

NiFe Cons

- High cost, but used banks can sometime be found at bargain prices.

- Moderate efficiency (80%)

- Need a lot of watering and venting

- High rate of self-discharge (30% per month)

Rejuvenating NiFe Batteries; Fom the www.navitron.org.uk forum. ( with some of my experience added )

If they have been left discharged for many years then, assume they will recover and try a low amperage charge over a long time. If there's a label with the ampere hour capacity it might also give you the charging rate. Halve the recommended charging rate and charge them for at least twice the time. And still watch out for them getting hot and take regular voltage measurements. Reduce the charge current if they start getting above "warm". Stop charging if they continue to get hot. Should come up to about 1.4v per cell. Might be a little higher or lower dependent on the charge current.

After standing for a while after a charge, they will need a gentle discharge. Suggest a current that is the equivalent of one tenth of the ampere hour capacity (i.e. what is termed as the 10 hour rate.) This type of battery was intended for slow discharge - they don't have the high current grunt of a lead acid battery. If the cells are going to recover, then you will have to repeat the gentle charge/discharge process a few times to restore their capacity. You can work up to higher charge/discharge currents as the cells begin to recover.

As they are old there might have been some electrolyte leakage from the top of the cells with a build up of powdery scale, also might be some on the terminals. Needs to be cleaned off carefully. If there has been leakage then it's possible that the cells have completely dried out and that that recovery will be poor. Some types of NiFe cells could be topped up but again you have to be careful because overfilling can lead to more loss of electrolyte. Leave 3/4 inch of air in the top of the battery as the electrolyte will expand when charging.

Reconditioning

Reconditioning alkaline cells (either NiCd or NiFe) means cleaning them out, replacing the old electrolyte with new electrolyte, and charging the hell out of them. The optimum life of the electrolyte is around 5 years, so you should get better performance by replacing it. Use rubber gloves and goggles and have a supply of vinegar on hand in case you spill electrolyte on yourself. Washing in water will do the trick too. While alkaline electrolyte is not as fierce as the sulfuric acid used in lead-acid cells, it can still burn, especially if it gets into your eyes. Do not freak out if you get some on your skin, just casually rise it off. No need to panic. It will attack open cuts first and it breaks down the tissue, but even then it takes hours.

Rinse the emptied cells with distilled water until they are clean. Getting them perfectly clean is would require dozens of flushes. We stopped at three. In NiCd cells, the electrolyte can contain minute amounts of cadmium, so handle it as hazardous waste. In NiFe cells, the electrolyte will do a great job of breaking down fats in the sewer. We have a Kentucky Fried Chicken upstream of our problematic sewer lines so we did the street a favor and poured it down the drain. You can also neutralize it with vinegar or hydrochloric acid, HCl, available from any pool supply house and you can compost it.

Mix the new electrolyte using technical grade potassium hydroxide (KOH). This is available from most chemical supply stores. Stir the KOH into distilled water in a large plastic container. I use a clean, 32 gallon, heavy duty, plastic trash can. Keep adding KOH until the specific gravity of the electrolyte is between 1.2 and 1.25. We added 3.53 pounds to 1 gallons of water to get to 1.23. And our batteries needed about .6 gallons each. If you add too much KOH, simply bring the specific gravity down by adding more distilled water. Use a clean; never used with a lead-acid battery, temperature-compensated hydrometer to measure the specific gravity of the new electrolyte. Don't worry if you can't find a temperature compensated hydrometer, the temperature does not change the specific gravity enough to bother with it. When the KOH dissolves there is an exothermic reaction. It will give off heat. So add the KOH slowly; about a pound per gallon at a time, mix thoroughly. I use a hunk of clean plastic conduit to stir the mixture, and wait for everything to cool off before making really accurate specific gravity measurements. Mix all the electrolyte you will need at the same time if possible. This assures uniformity in the electrolyte. Then add 15 grams of Lithium Hydroxide for every 10 gallons of electrolyte. Lithium Hydroxide is available off eBay at about $70 for 100 grams.

Cost: In all we purchased 215 pounds of potassium hydroxide off eBay at a cost of $450 including shipping and 100 grams or lithium hydroxide for $70, and 120 gallons of distilled water for $140. You will need the extra distilled water for washing out the batteries. New terminal lugs and 2/0 cable, about $65. Out total was $725 for reconditioning 56 batteries. And we spent many hours for a bank of batteries that might provide 350 amp hours at 12 volts. They are roughly equivalent to two, 100 amp hour lithium batteries with a total cost of $2000, but the lithium batteries will need no watering, and will take up a fifth of the space. So it comes down to what you need and what you have available. We got these NiFe batteries for free so they work out well for us.

NiFe Maintenance

NiFe, the nominal is 1.2V,

Charging:

For a 1.2V cell: Equalise 1.65v, Boost/Adsorb 1.55v, Float 1.45v For a 1.2V cell: Equalise 1.65v, Boost/Adsorb 1.55v, Float 1.45v

NiFe seems to be charged by applying a voltage of about 1.55V to 1.65V By charging at the high level of voltage, it does however seem that a regular check of liquid level is needed.

Floating:

There seems to be a convenient upper float voltage of 1.44V By convenient I mean, the voltage where they can work for months without any visual maintenance check.

Amps:

It seems that they are most happy at no more than 1C. Some recommend 1/5th C or C/5 where C is the amp storage capacity of the battery, for instance 10A, 30A or 100A It is permissible to discharge continuously at any rate up to 25% above normal, and for short periods at up to six times normal. When the normal discharge rate exceeds this value, abnormal voltage drops will occur.

Sample Power Inventory; In July we used 66 Kw / day

12v DC, 270 amps, Hydraulic pump for Autopilot 1/4 * 3240 watts

Chart Plotter 16 watts1.

Ice Maker, Ice n Easy 216 watts

Navigation Lights 1/3 * 200 watts

Total ((1/4 * 3240) + 216 + 16+ (1/3 * 200)) * 24 hours = 26.6 Kw

57 Batteries, Each 1.2v, 200 AH 20c = 57 * 1.2 * 200 *.5 *.85 = 5.8 Kw

6 - 50 watt solar panels = 300 wh * 6 hr sun = 1.8 Kw. Newer panels are typically 320 watt for $200. 8 of those with 6 hours of sun would provide. 320 * 8 * 6 =15 Kw

Typical wind generators out put 1 to 2 Kw a day.

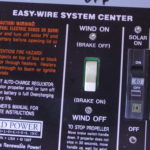

Inverter/Charger: TRACE_SW4024MC2UserGuide

Disconnect: Trace-DC-Disconnect-Owners-Manual

Anytime the Trace Inverter/Chargers are disconnected from the batteries the settings must be restored. Crew member Jeff Miller worked up the following cheat sheet of the setting that need to be changed from the defaults: Inverter Cheat Sheet

Tony 10kw Generator

Kolher Operation Kolher Service Parts Kolher Service Yanmar Service Manual

DC Loads

Forward Cabin

2 - 24v Water Supply Pumps 5 amps 2 - 10

2 - 12v Bilge Pumps 2 amps 2 - 5

1 - 12v Macerator Pump 16 amps 1 - 20

1 - 12v Cabin Top Winch 60 amps 1 - 100

1 - 12v Forward Mast 10 amps 1 - 15

1 - 12v Lighting 2 amps 1 - 5

Cargo hold

1 - 24v Accessory 10 amp 1 - 10

1 - 12v Companionway Winch 80 amps 1 - 100

1 - 12v Accessory 10 amp 1 - 10

2 - 12v Engine Room Cooling Fans 10 amps 2 - 15

1 - 12v Lighting 2 amps 1 - 5

1 - 12v Main Mast 10 amps 1 - 15

1 - 12v Deck Crane Controls 20 amps 1 - 30

Engine Room

2 - 24v Hydraulic Pumps 36 amps 2 - 45

1 - 12v Watermaker Lift Pump 10 amps 1 - 15

1 - 12v Watermaker Controls 3 amps 1 - 5

1 - 12v Hydraulic Control System 4 amps 1 - 10

1 - 12v Main Engine Hydraulic Pump Clutch 5 amps 1 - 10

3 - 12v Coolant Pumps - Intercooler / Variable Pitch Control / Transmission 3 amps 3 - 5

2 - 12v Fuel Transfer Pumps 15 amps 2 - 20

3 - 12v Bilge Pumps 3 amps 3 - 5

1 - 12v Lighting 2 amps 1 - 5

Aft Cabin

1 - 12v Macerator Pump 16 amps 1 - 20

2 - 12v Bilge Pumps 3 amps 2 - 5

1 - 12v Lighting 2 amps 1 - 5

Pilot House

1 - 24v Radar 7 amps 1 - 10

1 - 12v HF Radio 15 amps 1 - 20

1 - 12v VHF Radio 15 amps 1 - 20

1 - 12v Chart Ploter 3 amps 1 - 5

1 - 12v Lighting 2 amps 1 - 5

1 - 12v Navigation Lights 10 amps 1 - 15

1 - 12v Autopilot 4 amps 1 - 10

1 - 12v Relay Control 5 amps 1 - 5