Love Me

So why this boat? Seeker’s tender will not be a dingy used for getting from a mooring to the dock. This boat is an extension of Seeker. It will be a VW diesel engine powering a jet pump. The tender needs to be a work platform for the ROV, towing equipment such as specimen nets and sleds. It needs to be able to be beached on a rocky shore, and make it back out through surf. I needs to run on diesel so it is safe and can share Seeker’s fuel, it needs a range of 100 miles. The jet pump will make it safe for working around divers and marine life, able to avoid fowling lines, capable of deploying a “mail box” to blow clean water down to divers or excavate holes at archaeology sights and even allow it to be adapted to be used as a water pump for dewatering.

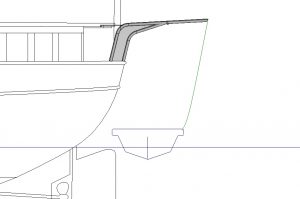

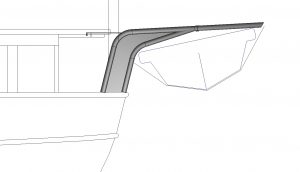

Jack Carson who drew the lines for the hull of Seeker, gave us a model of a tender with a deep V hull, well suited for choppy water and surf. To convert the model into plans I dissected it to make it easier to measure and then created a CAD drawing from the the pieces. The design has a couple of great ideas in it. It’s basically a RIB or Ridged Inflatable Boat but instead of inflated pontoons which wear out and leak it uses ridged foam that is sandwiched between two sheets of aluminum and which is held in place by a vinyl cloth cover. The foam will extend 6 inch beyond the aluminum sheet to provide a soft bumper that wraps around the boat. And squared off nose gives it a good surface area to push against hulls for moving boats around as well as an elevated work deck.

I cheated and use our CNC cutting table. By putting an ink pen in the router I simply have the pattern drawn onto poster board. See more about the CNC table here: Ballpoint Pen CNC Tool

Poster board is about the limit for a 16 inch model; the heavier card stock works much better even when I increased the scale to 1.5 in to 1 ft which makes the model 24 inches long.

Scaling Weight from Model to Full Scale

Scaling Weight from Model to Full Scale

Next came a 1/6 scale model cut on the plasma table from sheet metal and with insulation foam. The 11.88 lbs, 5.39 kg model, including a 4 pound weight at the transom to simulate an engine and jet pump was placed in the tub. Free-board is the important number here. Free-board is the lowest distance between the water and where the water would start to pour into to boat. The model has 2 inches of free-board and that would translate tow 12 inches at full scale. That math is easy. The model is 1/6 scale, so 2 * 6 = 12 inches. That assumes that the weight of the model will scale correctly to the weight of the full sized boat. We know a 16 ft boat with engine and equipment can be as much as 2500 lbs, 1134 kg.

So what would the weight of our 1/6 scale model be if it were full size? It’s certainly not 11.88 lbs * 6 = 71.28 pounds! With some help of smarter people I learned the math is rather simple and makes sense. We need the cube of the ratio. 1/6 * 1/6 * 1/6 = 1/216. So 11.88 * 216 = 2566 lbs, 1164 kg. So if we want to maintain 1 ft, 0.3m of free-board, we need to keep the boat’s weight under 2566 pounds.

Weight Estimate

A 2000-2003 VD TDI engine weighs in at 361 pounds. A Berkeley 12J pump is 125 pounds. 2o gallons of diesel is 140 pounds. Total 626 pounds.

The hull is: 44.7 sqft bottom, 54 sqft bulwarks, 36.6 sqft under side of deck, 38.2 sqft deck, 10.62 sqft transom, estimate tanks, engine housing, swim deck, etc, 80 sqft. Total of 264.12 sqft * 144 in/ft * 0.1875″ thick * 0.103 lbs/cubic in = 734.5 pounds

Foam, vinyl, winch, cleats, etc 100 pounds.

Total Estimate: Drive 626 + Hull 734.5 + Misc 100 = 1460 pounds. 1100

With 1 ft of free-board with 2566 pounds of load less 1460 pounds for the boat, leaves 1100 pounds for crew and cargo.

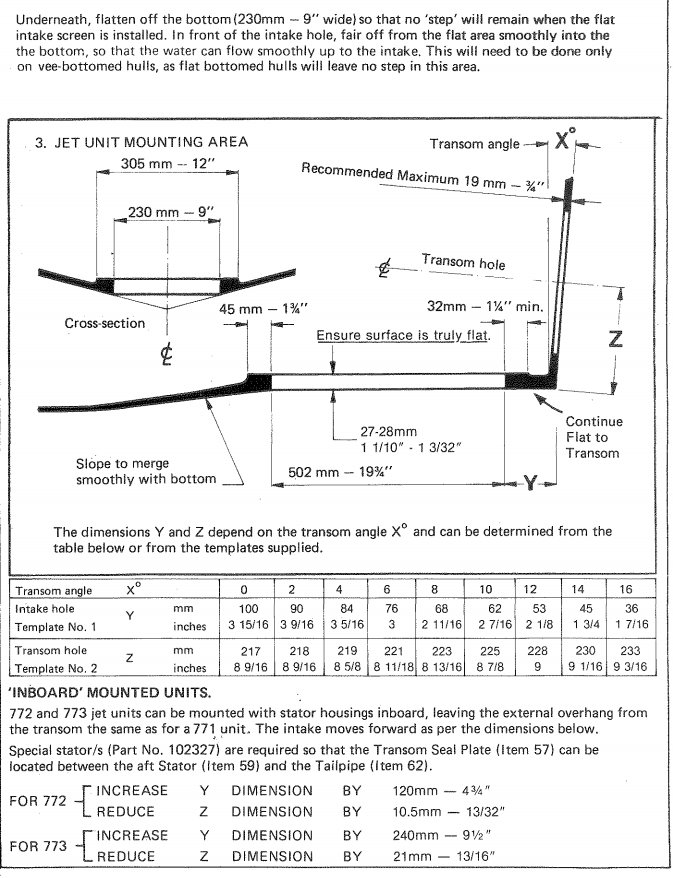

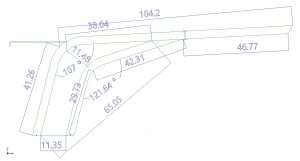

Modifying the Hull

We now have a Hamilton 773 jet pump, and some good advice about adding a “delta pad” or a “keel pad”, which is a flat triangular keel to the bottom of the hull. The pad is only 13.5″ wide at the transom but extends to a point just over half the length of the hull. It provides a flat mounting surface for the pump as well as a lifting surface for planing and to insure the pump intake is more often that not submerged. Hamilton also recommends that the deadrise, or angle that the sides of the hull make to each other, remain constant over the aft halve of the hull. Most deep V hull tend to flatten out toward the aft so as to provide more planing surface. Fortunately, adding the keel pad also provides a consistent deadrise of about 47.5 degrees. With 1 foot added to the depth of the keel the hull now sits higher in the water even when waited with another 2.6 pounds which scaled up; ( 2.6 * 216 ), is about 560 additional pounds of cargo for a total of 1660 pounds for crew and cargo. Fully loaded it would come to just under 3,500 pounds. We could not lift that much with the davits, but it’s nice to know we can haul that much from shore to Seeker.

Engine and Drive

I really want to power this boat with a diesel engine. VW diesels answer the weight to hp issue of John Deere 4045 or a Cummings 4BT, but they generally are covered with sensors, wires, and have a computer. All of those things would likely be a sources for problems in a salt water environment. We picked up a 65 HP, 1996 VW 1.9L Mark3, AAZ, Turbo Diesel Engine from a Passat / Jetta with a mechanical injection pump or MTDI for $400. A great price, mainly because the seller loved what we are doing with Seeker. Eli and Russ, two of our crew members drove it down from Michigan, and Stephen Cox, another crew member is going to go through it and turn it up so we can get as much horse power as possible. The air cleaner housing came out of an 2005 Mercury Grand Marquis. After destroying two starters with our fabricated starter mount, we cut the bell housing off what was thought to be a 1999 VW Bug’s manual transmission. That fit the 1.9 AAZ engine so we found a start that fit the bell housing from a 1992 Volkswagen Corrado G60 with a 1.8L engine. Franken boat lives.

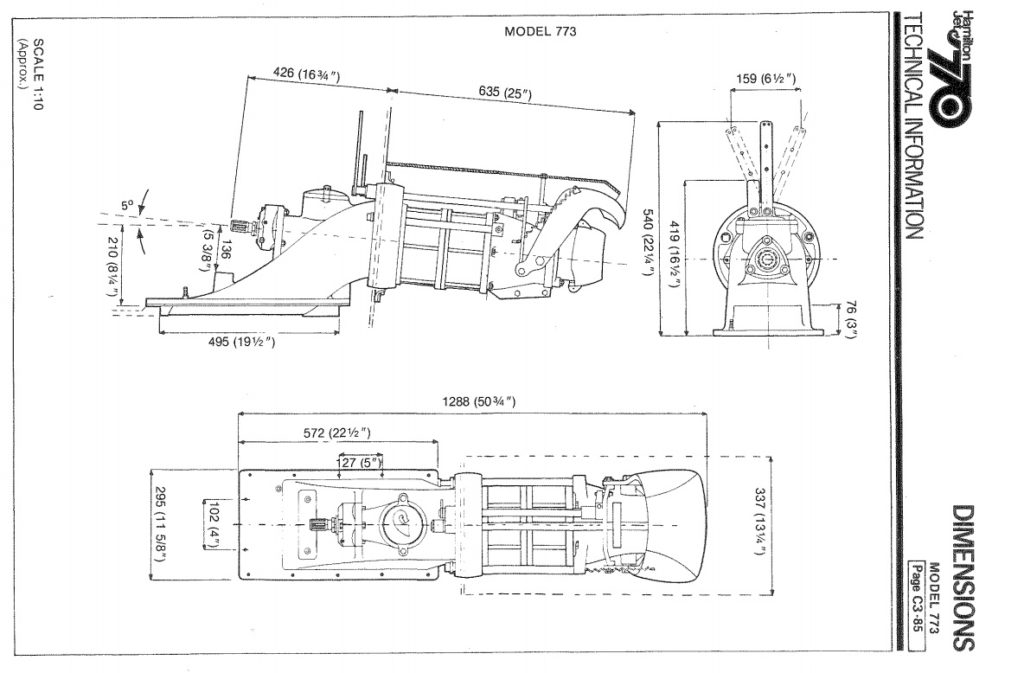

A jet pump seems to be the best drive idea, as it is shallow draft, can be grounded without damage, will not chew up sea critters or swimmers, will not easily foul tow lines, nets and other gear being used over the transom. And with the engine mounted a bit forward of the transom it provides better working access over the transom and jet pumps don’t need a gear box for reverse. A Berkeley 12JC-A Jet Pump is designed for 3000 rpm and up in order to pump upwards to 5,000 gallons per minute, which looks to be a good enough match for the VW 1.9. But Doug Westover, one of our viewers hails from Ontario, land of the jet boat and there the favorite pump is a Hamilton and Doug found us a great deal on a Hamilton 773 out of Little Current, Ontario. The Hamilton pump is superior to the Berkeley in it’s ability to run in rough water where it will often ingest air, and it’s ability to clear seaweed through the impellers. The Hamilton 773 is recommended to have a 130 HP engine pushing it so our VW 1.9 might be too light, however we are looking for economy and power to push instead of winning any races. And we can can always trade up from the 1.9 AAZ to the 19 TDI which will fit the same space.

Resources: 772 773 – Owners Manual and 770 – Workshop Manual

Parts in the USA: KEM Equipment http://www.kemequipment.com Kodiak is the same as the Hamilton 773: Kodiak Marine Parts Book

When Hamilton went to the 212 and stopped making the 3 stage in 92, KEM got the patents for it and started making 3 stage pumps exactly as Hamilton.

Davits

Gripes? Where do they come up these? A gripe is a line secured under a boat to hold it in place on a davit. And a davit is a marine jib crane.

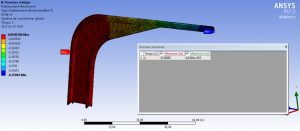

We asked our viewers to help with the FEA, or Finite Element Analysis which is a computer process that predicts if a structure is adequate for a specific load. My engineering background is “that looks strong enough” and all items are measured by the number of pounds they sustained before doing permanent damage to the structure. Engineers work from the other direction. They start with a design load then build a structure in the computer and plug in a “safety factor” such as 2.5 which means the structure should actually only fail when 2.5 times it’s design load is applied. The FEA simulation identifies the portion of the structure nearest the safety factor. Unfortunately this is a complete waste of time on us farm boys who know they do this and will apply twice the recommended load with little concern. …unless it is Chinese made.

Francys Therrien from Montreal, Quebec stepped forward and modeled our davits in CAD, ran the FEA process and generated a detailed report. It was best to run the FEA without the attachments to the pilothouse roof, but we will attache them to the roof as they will add support to the roof as well as gain some support from the roof. The bottom line is that each davit can be loaded with 3371 pounds and it stay within the 2.5 safety factor. So will I be willing to put 7000 pounds on one davit? Hell Yes!

Francys Therrien from Montreal, Quebec stepped forward and modeled our davits in CAD, ran the FEA process and generated a detailed report. It was best to run the FEA without the attachments to the pilothouse roof, but we will attache them to the roof as they will add support to the roof as well as gain some support from the roof. The bottom line is that each davit can be loaded with 3371 pounds and it stay within the 2.5 safety factor. So will I be willing to put 7000 pounds on one davit? Hell Yes!

Thank you Francys!