The rain held off today and Aaron, Jack and I got the last of the welding and grinding done on cabin tops and deck. In the shop Su and Betsy worked on the art of the next deadlight casting. “Some people care too much. I think it’s called love.” — A.A. Milne

Crime Scene

Oh NO! This is what we woke up to this morning in the shipyard. A chalk outline of our mischievous little helper. Suggesting something like an episode of CSI Shipyard, we lost all thoughts of sugar plums dancing through our heads. We’ve got Jezebel and Tinka scouting the perimeter and hopefully something will turn up.

Oh NO! This is what we woke up to this morning in the shipyard. A chalk outline of our mischievous little helper. Suggesting something like an episode of CSI Shipyard, we lost all thoughts of sugar plums dancing through our heads. We’ve got Jezebel and Tinka scouting the perimeter and hopefully something will turn up.

As far as other clues, we don’t have much to go on. The last time we saw Rizzo the Elf, he was swinging on Seeker’s Christmas Lights. But a storm is moving in and there is a fair amount of humidity out there — could he have been electrocuted? He seemed so happy and carefree and though he does tend to be a bit of a troublemaker at times, he’s still a part of the Seeker Crew. What happened?

Casting Deadlights – Part 1

Sodium Silicate Sand Rocks! Especially for the occasional casting or big casting. Traditional Green Sand requires, skill, storage, and a sand muller to recondition your sand. And the difficulty increases with the size of the casting. Sodium silicate sand uses inexpensive fine silica sand, and sodium silicate (water glass) which reacts with CO2 to harden the sand. 200 pounds of mix cost less than $30.

Sodium Silicate Sand Rocks! Especially for the occasional casting or big casting. Traditional Green Sand requires, skill, storage, and a sand muller to recondition your sand. And the difficulty increases with the size of the casting. Sodium silicate sand uses inexpensive fine silica sand, and sodium silicate (water glass) which reacts with CO2 to harden the sand. 200 pounds of mix cost less than $30.

I’d like to thank our local Tulsa foundries for sharing their knowledge. Especially Scott and Adam at R & D Foundry and Don Doss at Metal Dynamics.

And many thanks to Seeker crew: Jack, Su, Hugh, and Paul who helped get us through the learning curve casting our first porthole deadlight.

And finally to Betsy who has been working on our new web site. You can now buy from our Junk Store and help support our work.

Junk For Sale!

Our store is finally open. Stop in and see the beginning of much more to come.

Let’s Go Shopping!

Today we added the 34 oz Thermal Mug. This is just like the mug we give our visiting crew. It stands 8″ tall and holds enough liquids to keep you refreshed and hydrated.

While you can probably find products like these at the store for less, it won’t be an official SV Seeker piece of junk. If you can’t afford it, please don’t buy it, but if you do — thank you very much for your help in funding The Boat the Internet Built!

Success Casting the Deadlight!

Got it on the second try! But we had a great team. Paul, Hugh, Su and Jack all pitched in. Having a crew is wonderful.

Got it on the second try! But we had a great team. Paul, Hugh, Su and Jack all pitched in. Having a crew is wonderful.

With the mold ready we fired up the furnace, and before we finished our break the aluminum was hot. Actually too hot. Way too hot. But I decided to pour it anyway knowing that a grinder can wipe away our casting sins just like it does our welding sins.

Being so hot, it poured like water. About 25 pounds of aluminum went into our 200 pound mold.

Our lawyer Hugh Hood pulls the casting from the drag. The moment of truth was here.

The overly heated aluminum; I seriously need to turn that furnace down for aluminum, gave us a rough surface, but the casting was all intact. And we actually like the rough surface. It adds character. Paul’s work on the design as well as the inscription on the inside came out beautifully.

“When I let go of what I am,

I become what I might be.” –Lao Tzu

The symbol dates back to 3200BC from Ireland and is found in many cultures. To the Celtics it stood for the earth, the sea, and the wind. Gakyil or ‘wheel of joy’ to the Chinese. The Dga in Tibet used to describe all forms of joy.

The symbol dates back to 3200BC from Ireland and is found in many cultures. To the Celtics it stood for the earth, the sea, and the wind. Gakyil or ‘wheel of joy’ to the Chinese. The Dga in Tibet used to describe all forms of joy.

Casting Porthole Deadlights – First Failure

It didn’t work but I am accustomed to that on the first try. Come to think of it, I am accustomed to that on the second and third try too. But we have great hope for our plans based on watching the sand slowly crack and fall out while we carefully moved the top have of the mold. But it was still a very enjoyable day with Hugh and Su joining Paul and I.

Tomorrows plan calls for building a steel reinforcing frame that will be embedded in the sand for the top side of the mold and keep it from falling apart.

This was the first time we melted aluminum in this furnace and it was amazing how fast it went. A full 30 pound crucible was ready in less than an hour, long before we had the finished the mold. Tomorrow we will do the molding first and not be so rushed, then fire the furnace once we have a good mold ready.

Always a beautiful sight. Even if you’re just pouring ingots.

Casting Test

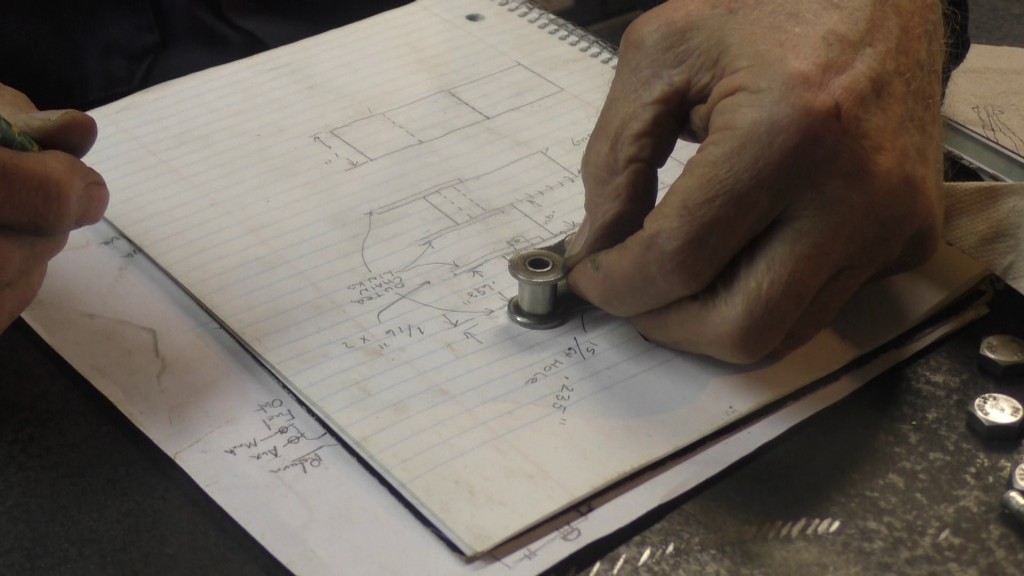

Remember those winch capstans we were trying to cast?

We’ll we’re back messing with it. I had one more bock mold that I know is too thin to work, but it made a great test sample. Paul and I used 2″ thick ceramic blanket to make a temporary burn our furnace that will let me use larger block molds. And we got it to 1000F with a propane burner in 2 hours that will let us not just burn it out but also let us use the better burner to melt the NiBrAl (Bronze) so we can pour into a hot mold. That’s all good news!

We’ll we’re back messing with it. I had one more bock mold that I know is too thin to work, but it made a great test sample. Paul and I used 2″ thick ceramic blanket to make a temporary burn our furnace that will let me use larger block molds. And we got it to 1000F with a propane burner in 2 hours that will let us not just burn it out but also let us use the better burner to melt the NiBrAl (Bronze) so we can pour into a hot mold. That’s all good news!

We also experimented with adding letters and patterns to our dead lights for the port holes and we like the results. Tomorrow we hope to cast our first dead light in aluminum.

Rudder, Hatch, ROV and other

I had a great Thanksgiving vacation with an old salt. Dave spent his time steering a destroyer and gave me an ear full of advice. Much of it was actually useful. 🙂 And we got several projects moved down the trail.

SV Seeker says goodbye to Dave Fickle

I have thoroughly enjoyed working beside Dave Fickle this week. We worked on a variety of task including the ROV, the propeller shroud, main hatch, and rudder quadrant. Dave is a kick. Always direct and opinionated and swears like a sailor. My kind of guy. Miss you already amigo.

Mary and Fred stopped in for a visit from Kema Texas. Check out their blog about sailing and travels at Svgimmeshelter.com