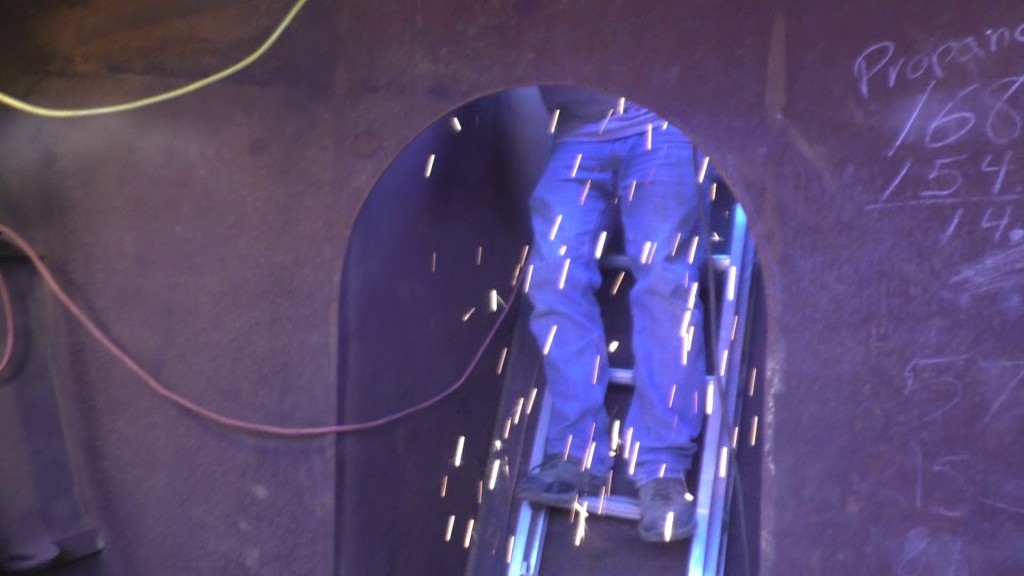

For all those thinking about helping on the boat. I want to share a warning from a concerned YouTuber.

For all those thinking about helping on the boat. I want to share a warning from a concerned YouTuber.

Farlig66: “… You may well not give a fuck about what I think about your choices but I’m gonna tell you anyway for the greater good: Your attitude of “your safety is your responsibility not mine” is a big fucking mistake and may very well lead you down the path of shit and litigation down the line. Safety takes teamwork where everyone watches each other’s back. Safety is a culture where everyone thinks about the consequences of their own and others actions, it’s about thinking through “what can go wrong here” before proceeding with due caution and mitigations in place… I sincerely hope none of your helpers, now or in the future, get hurt by your attitude…”

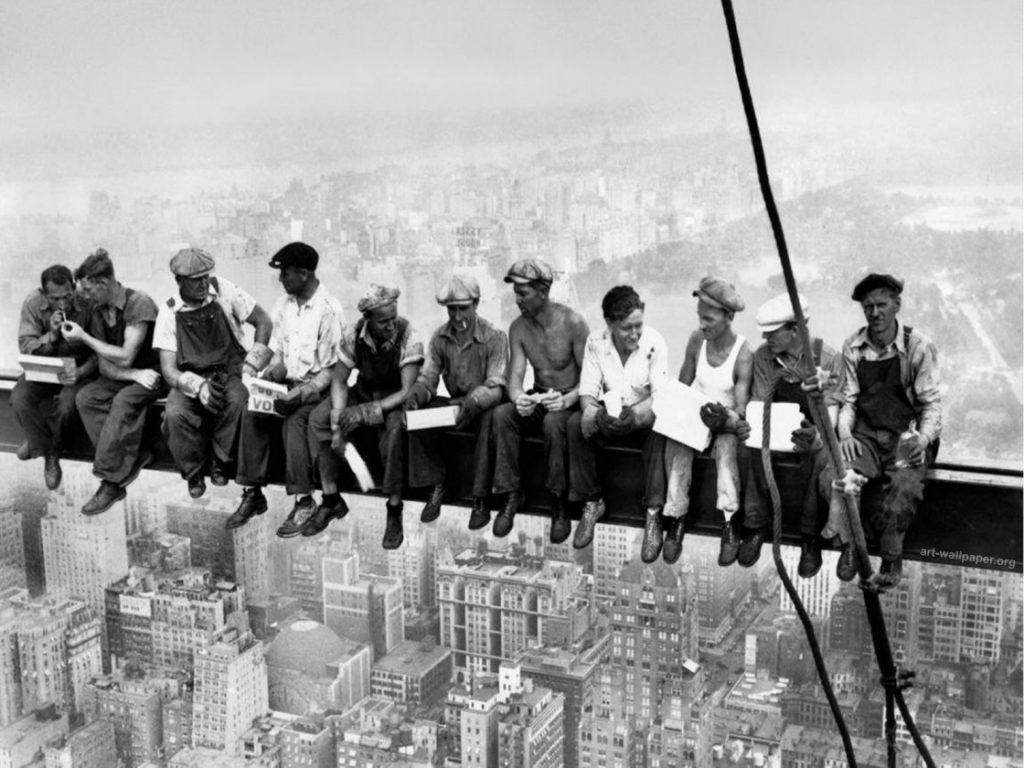

+Farlig66 I think if you look through a short list of civil court actions you will find the anything can lead to lawsuit. And I think that is because we have trained people to think that their safety is someone else’s responsibility. So now I hand you a cup of hot coffee and you proceed to take a quick swig from it, burning your tongue and dumping it in your lap and it’s my fault, because it was too hot. You take zero responsibility for your lack of awareness. If that is you then I don’t want you on my team. You need a nanny. And frankly there are people that come work with me that can do things that I can not do, and it is not my business to tell them to work at my safety level. Marc from Vienna Austria was holding onto the pilothouse roof with one hand and leaning out over the side helping me mount a dragon. I warned him that I did not want to stop work in order to take him to the hospital, and he demonstrated that he could actually swing easily from one hand. Turns out he practices parkour, so he was perfect for that job. When we start setting rules for what is safe, we ignore individual talents and as accidents continue we add more rules until everyone is forced to work as if they are a stupid, unaware, clutz. I do appreciate the conversation. It’s important that I can convey our safety policy so the mamma’s boys can safely avoid showing up to work. If they do show up because they recognize that they have been robbed of a meaningful existence by their nannies and they understand that it is up to them and them alone to decide what they will attempt. I really like it when I have folks look at me and say “No, that’s not something I feel like I can do.” That is an awesome team member. They looked after themselves first, and in doing so looked after their team as well. Because if you can’t hold that plate over my head while I tack it, I sure as hell would like to know that up front. 🙂

We were closed last weekend so we could get some house work done but we managed to cobble together a video and we did get the dragons both mounted, but the solar tank is still leaking. 🙂 Anyway! I rambled for a bit in this video about the kind of boat Seeker is, and is not. Combine that with listening to the book: “The 7 Habits of Highly Effective People: Powerful Lessons in Personal Change” and I figure it’s time to start drafting a Mission Statement for Seeker. And a good mission statement is not crafted in the back cabin. It’s done on deck with the input of crew, because it is both skipper and crew that will have to live by this statement. Maybe we should call it our code.

We were closed last weekend so we could get some house work done but we managed to cobble together a video and we did get the dragons both mounted, but the solar tank is still leaking. 🙂 Anyway! I rambled for a bit in this video about the kind of boat Seeker is, and is not. Combine that with listening to the book: “The 7 Habits of Highly Effective People: Powerful Lessons in Personal Change” and I figure it’s time to start drafting a Mission Statement for Seeker. And a good mission statement is not crafted in the back cabin. It’s done on deck with the input of crew, because it is both skipper and crew that will have to live by this statement. Maybe we should call it our code.