Pouring Lead into the Keels

Many thanks for the help last weekend from Jack, Bill, John, and especially Joey who drove down from Wisconsin.

Our Crew

If you haven’t taken a look at our Crew page lately, it’s worth the journey. Slow but steady, the pins in our map are growing. These are people, just like you, that have made the journey to Tulsa to help build Seeker. While the majority are still local, we’ve found by meeting so many great people that the world is much smaller and the people’s hearts much bigger that we ever imagined.

Thank you to everybody who has helped with “The Boat the Internet Built” and welcome aboard to those who plan to make the journey in the future. For those of you who can’t make the trip for one reason or another, we still value your friendship and support.

Helpful Links

For more details on our crew, Meet our Crew

If you’d like to visit, Welcome Aboard

Want to see who’s coming and what we’ll be working on? Calendar

If you can’t make the journey but want to contribute, visit our Junk Shop

Basic Google Maps Placemarks error: JavaScript and/or CSS files aren't loaded. If you're using do_shortcode() you need to add a filter to your theme first. See the FAQ for details.

River of Lead

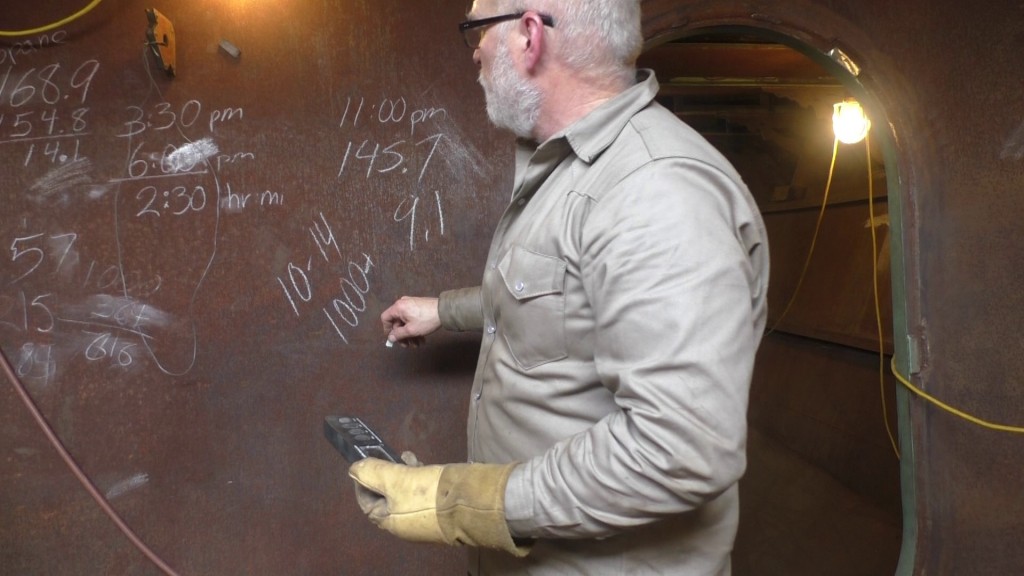

We had a awesome weekend. Two more more 1000 pound pours and we are getting our process down. And pouring it is amazing to watch. I am almost delighted that we have 17 more of these to do. 🙂

Lead Lead Everywhere

1000 pounds, the first of 20,000 pounds. Besides a small leak in the old melting pot our Harbor Freight dual burner propane stove converted to lead smelter was doing good. 1000 pounds ready in 5 1/2 hours having burner 14 pounds of propane. So now we know we are going to need 280 pounds or about 66 gallons .

Once the pot was completely molten the plan was to heat the drain pipe up to melt the lead plugging it and then let the entire contents flow into the keel. The problem was that there was not enough flow and heat to overcome the chilling effect of the 8 feet of 1 1/4″ pipe that the lead had to flow through. So after about 10 seconds of flowing, it choked off at the bottom of the 6 foot pipe dropping down into the keel. It then quickly filled the pipe and started over flowing at the top, as the down pipe was only hanging on the end of the pipe from the melting pot.

So then it became a beautiful waterfall of lead. It really was something quite interesting to see. 1000 pounds of molten lead cascading into the keel and freezing instantly as it came into contact with the steel as it splattered.

Cleanup begins tomorrow night. Fortunately the lead has no interest in sticking to the steel. We think the best plan going forward is to put a pour spout on the pot as the pot is already designed to be tilted. So once it’s melted we will simply pitch the pot over and very quickly pour the entire contents before it has any time to cool.

Actually clean up began tonight. It tool me an hour to pick the majority of lead splatter off my pants and boots. 🙂

Step by Step Aluminum Casting with Sodium Silicate Sand

There is just something incredibly fulfilling about the heat, the noise, and making something from liquid metal.

Sodium Silica Sand Casting Rocks!

* Fewer Failures

* Faster Results

* Bigger Castings

* Less Equipment

* No storage

Resources:

Foundry Practices http://movingimage.nls.uk/film/1529

Building a Furnace https://youtu.be/f10hqYGIJCE

More Furnaces: https://svseeker.com/casting_furnaces.htm

Building a Burner https://youtu.be/P-A8uoWdBB8

Casting Propellers: https://svseeker.com/casting_boat_props.htm

Like Molasses in January

Somebody mentioned the molasses treatment for steel. There are lots of YouTube videos with car parts sitting for weeks in fermenting tanks of molasses and water, 1:10. I dismissed it, as I sure as hell am not going to turn the insides of Seeker into a fermentation tank. But then I found a bottle of molasses in the pantry today. Hmmm, so lets see what smearing it onto the steel does. At least until the rain washes it away.

All this is because we are seriously looking for a path that avoids sandblasting the interior of the boat. That would be a horrible job. And now that we have it on good advice that modern paints like POR 15 can deal with light rust without blasting we are hopeful. The trick is to remove as much of the rust as possible. Hence the molasses test. And I am not going to put this anywhere inside the boat till I can see that it works to some degree on the outside. This stuff stinks. And it’s not even started to ferment yet. But the dogs like it. What they don’t lick it off they let it dip into their hair before coming back inside the house.

Apparently molasses contains a small amount of phosphoric acid, and phosphoric acid is commonly used to clean rust. But the amount of phosphoric acid is also dependent on the production process, so it may depend on the batch. However it might be that adding phosphoric acid to molasses would work better than just spraying phosphoric acid on, as it would hold the acid in contact with the vertical steel.

Here is the main post about PAINT. Recommendations and suggestions are welcomed.