Deck Crane – Part 1

It was really nice to have a pair of mechanical engineers around. Matt wanted to move something heavy so we took the morning to test fit the deck crane. And Drew has actually designed winches and cranes so he was the perfect person help us decide how to mount it. Sorry about electrocuting you Drew! 🙂

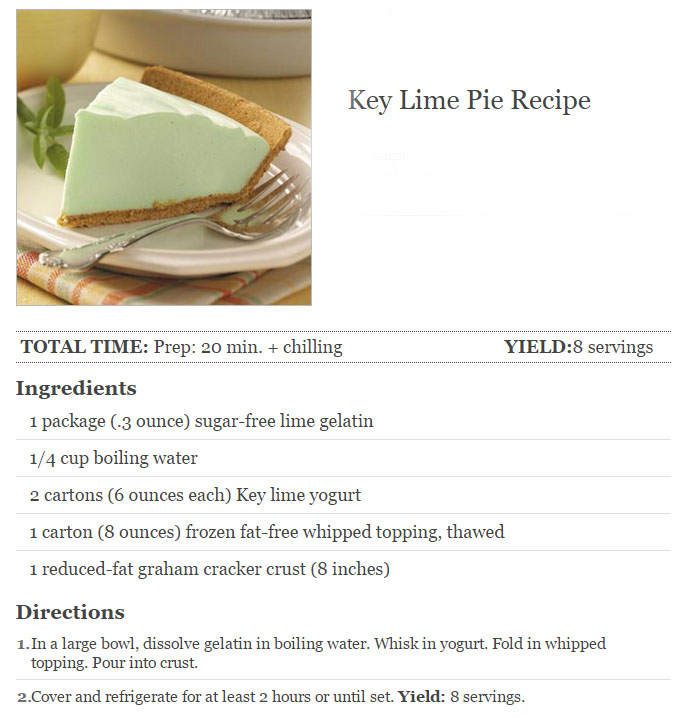

Key Lime Ice Cream Bars

In the worst heat of the summer, Rod Troyer from Ohio stopped by for a long weekend. He helped with sand blasting and maintenance but we will remember him best for his Key Lime Pie.

Rod showed us how to make the pie using low-fat yogurt, sugar free jello, fat free cool whip and reduced calorie graham cracker crust which made it much healthier than the one we were making with 6 eggs, and 2 cups of sugar! The best part was that Doug could sit down with a fork and gobble up half the pie in one sitting and not instantly put on 5 pounds!

The calorie count for the filling was only about 200 calories for the WHOLE pie, but the Reduced Crust was 800 more calories. One piece (1/8 pie) would now add in about 125 calories.. or half the pie, about 500!

It was actually Doug who came up with a great idea that would further reduce the calories but even better — provide some portion control.

Key Lime Ice Cream Bars

The filling is still the same, but instead of the graham cracker crust, we picked up a box of low fat Graham Crackers. I spread a piece of plastic wrap on a cookie sheet broke the rectagular crackers into halves and laid out 16 halves in a big square (4 x 4) with their edges nearly touching. I then spread the filling mixture on top of the crackers (about 3/4″ thick) and pressed another graham cracker half on top. I then put the cookie sheet into the freezer for about 30 minutes to harden up the filling.

With a sharp knife dipped in hot water I sliced between the crackers making 16 sandwiches and wrapped each one in plastic wrap and tossed them into the door of the freezer. Each sandwich is only 60 calories… SIXTY CALORIES and Doug rarely snarfs down more than 2 in a sitting! He’ll be in that Speedo in no time!

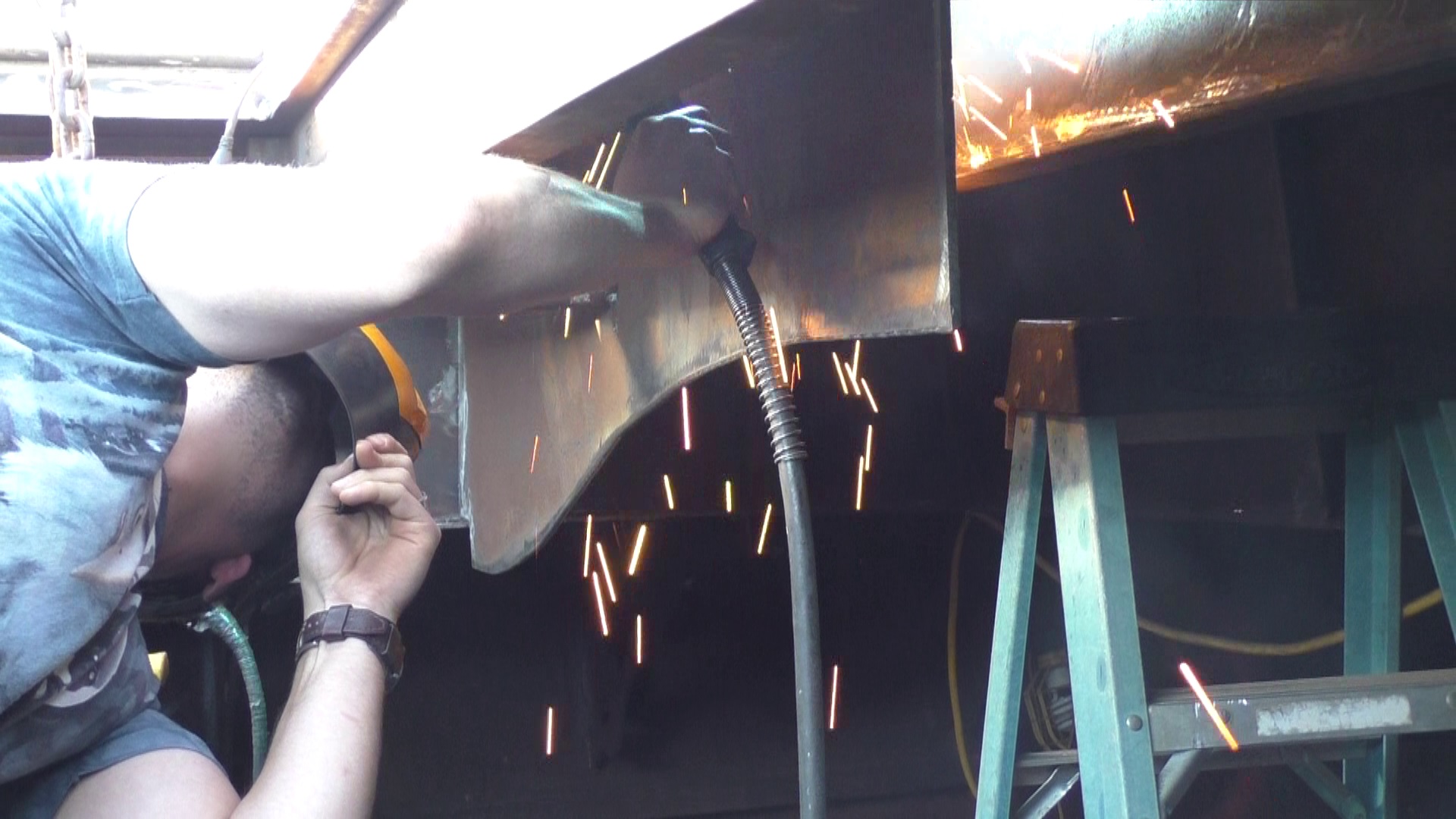

Scuppers / Engine Hatch / Mast Partners

The rain cleared up and got started on beautiful cool Saturday morning. Mike Love from Annapolis and I were joined by Richard and Dan from Oklahoma City, then Jack from Tulsa and finally Kevin from Michigan. The work consisted only a few items but complicated items that required a lot of cutting and grinding to get into shape. It’s those little parts that jammed back in some small hole overhead that really require a lot of patience. Because your going to work on them for days, and it’s going to seem like you got very little done. But they are getting done. Just keep it simple and keep moving forward. And doing it with a great set of folks makes it all the better.

Hatches & Freeing Ports – Part 3

Much gratitude for Arron “Mr. Welder” Buscavage who flew in from Lower Alabama (Florida). Randy Martin from Denton Texas, who stopped with his work cloths this time. And locals, Jack and Hugh. A great team and a great weekend.

Deck Crane

A very good day. Matt Hartel wanted some experience moving something heavy so the morning we switched plans to test fitting the 1 ton deck crane. The crane will pick up 2.5 tons, but it weighs about 1 ton. Drew Morgan, another mechanical engineer showed up so we make surprisingly quick work of it. It turns out to have been a really good idea to test fit the deck crane as we decided to change the mount location to make it easier to walk around. And then we decided on the amount of reinforcing that needed to be added for both the crane and the main mast.

Freeing Ports / Scuppers / Drains

It’s so nice just to be able to sweep grinding and plasma grit over the side. 🙂 I’m going to really like freeing ports, or scuppers, or the drains in the deck. what ever you want to call them. ….And sadly we said goodbye to two more friends. Randy headed back to Denton Texas today, and Aaron flies back to Florida tomorrow. That was a lot of great welding and grinding we got done. And tomorrow we welcome Matt, our second Nuclear Mechanical Engineer to visit. We may need to install a reactor.

Port Holes! Not Portals.

Randy from Denton Texas joined us for the day. Jack, Betsy and I got the Port Holes, not Portals, laid out. Huge showed up and did some clean up, and Aaron was Mr Welder the entire day. The job for tomorrow is to cut the freeing ports and grind steel fast enough to stay ahead of Mr Welder.