OMG! Their working on an outboard again!  Someone stop them.

Someone stop them.

I just love the diversity of people that come to help build Seeker. From tall ship captains, to truck drives, to nuclear reactor design engineers. Everybody has a skill and knowledge that becomes part of the boat. Danial and Rob, a pair of engineers from San Antonio, Texas stopped by and we put them to work testing the ROV’s tether and lend some inspiration. It was great to meet two young engineers that had a passion for building an racing. There car was with them and then were on a trip to Nebraska to compete. These are the kind of engineers that I love to see. The ones that get dirty, think outside the box, and have a love for what they are doing. Seeker crew are Awesome!

I just love the diversity of people that come to help build Seeker. From tall ship captains, to truck drives, to nuclear reactor design engineers. Everybody has a skill and knowledge that becomes part of the boat. Danial and Rob, a pair of engineers from San Antonio, Texas stopped by and we put them to work testing the ROV’s tether and lend some inspiration. It was great to meet two young engineers that had a passion for building an racing. There car was with them and then were on a trip to Nebraska to compete. These are the kind of engineers that I love to see. The ones that get dirty, think outside the box, and have a love for what they are doing. Seeker crew are Awesome!

For details and updates on the tether see: Winch & Cable

The snow birds intent on being “First” in the warm ponds are working their way south along with the cooler weather. The main mast is off to be galvanized. And it’s fun to be back inside the hull. We’re double welding the plates on top of the lead and adding frames to reinforce the keels. The lightening holes look awesome, but they will also give use tie down points for cargo or the occasional adventurous sailor. Our crew and viewers continue to be a great source of inspiration. We appreciate the love you show through ideas, supportive comments, gifts, and labor. I also love the diversity of our crew. Amateurs looking to build skills, pros looking to share skills, and retirees with the knowledge of the world. Thank You!

The snow birds intent on being “First” in the warm ponds are working their way south along with the cooler weather. The main mast is off to be galvanized. And it’s fun to be back inside the hull. We’re double welding the plates on top of the lead and adding frames to reinforce the keels. The lightening holes look awesome, but they will also give use tie down points for cargo or the occasional adventurous sailor. Our crew and viewers continue to be a great source of inspiration. We appreciate the love you show through ideas, supportive comments, gifts, and labor. I also love the diversity of our crew. Amateurs looking to build skills, pros looking to share skills, and retirees with the knowledge of the world. Thank You!

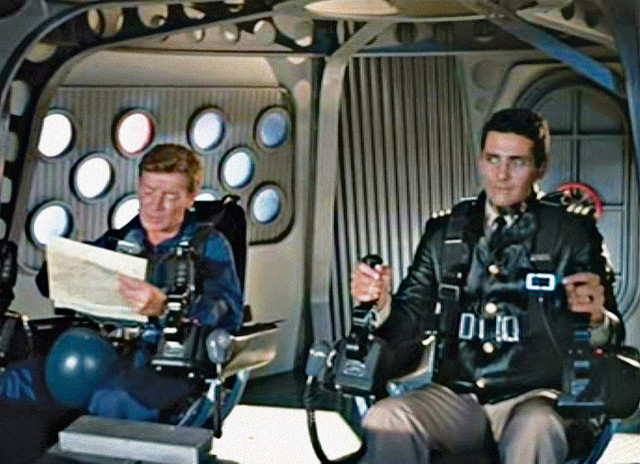

Remember the flying sub in “Voyage to the Bottom of the Sea”? I have always loved lightening holes in aircraft, and now they will be a visible part of Seeker.

Remember the flying sub in “Voyage to the Bottom of the Sea”? I have always loved lightening holes in aircraft, and now they will be a visible part of Seeker.

It took the better part of two days but we got one of ten frames cut for the cargo hold. It was not one of our better weekends. Getting a hole cutter best suited for sheet rock to cut through 3/16″ aluminum took lot of skill and patience from Doug Stout. And we had more that our fair share of do-overs on patterns for the frames themselves. And the heat in the hull finally drove us out. We’re looking forward to more cool weather.

That second capstan has been siting in the lathe from over a month, and Doug Stout a retired machinist showed up and not only completed the bore but showed us some really nice tricks. Tomorrow is the final fit up. The rest of us spent the day stretching and breaking ROV cable. Very surprising is how crappy Cat5 is and how much better RG6 is at haft the cost of Cat5. The tick now is to find some strength members that can be added to the RG6 that will take the load before the RG6 reaches it’s limits.

Thank You! Thank You! Thank You! About 50 folks showed up for last week’s open house and we got a year’s worth of good vibes. Seeker is more that a boat, she is a crew and a following of people that love making things, building a better world and who love life. Thanks for sharing your love!

Thank You! Thank You! Thank You! About 50 folks showed up for last week’s open house and we got a year’s worth of good vibes. Seeker is more that a boat, she is a crew and a following of people that love making things, building a better world and who love life. Thanks for sharing your love!

Special Thanks to Scott Rokeby for the aerial shots. You can get Scott to shoot your event. See: https://www.facebook.com/DaedalusImagingLLC/

Danial and Rob, two engineers on their way to race their car in Nebraska, stopped in and we tested a length of RG6 inside some tubular webbing. Unfortunately the tubular webbing stretches about 35% with just 300 pounds of load and that was too much for the RG6. So we need your help. But please stay within the parameters. We are not a government agency and we do not want to act like one.

We are looking for: Cheaper, Stronger, Easier, and More Widely Available for 60 cents a foot.

So what is the best combination of polypropylene tubular webbing, coaxial cable and strength member, either steel of synthetic so that we have a low cost, neutrally buoyant, anti-strumming, tether that can sustain a 1000+ pounds of load when towing?

How much will coaxial cable routinely stretch?

What is the working load for common RG6 with a messenger wire?

Details and Updates are here: http://wp.me/P6ivyU-SJ

Two weekends ago Betsy and I were in Florida checking out a Junk Rig. Last weekend, Bart, Jack and I were at the Tulsa Mini Maker Fair showing off Seeker, the ROV and recruiting help. And this weekend is our open house. So when do we have time to build something? We are building something. We are building a community, and it is that community that is making Seeker possible.

Drew has the new guidance IMU component for the ROV and working on new code for it.

Patrick has gone through OpenROV’s code and started adapting if for Seeker’s ROV.

We met Barry from Navico at the Maker Fair, and he happens to be the mechanical engineer that worked on the Lowrance side scan transducer. He answered some important questions and will be a great resource moving forward.

We also met Zachary who had a great idea for using Coax instead of Cat5 for the ROV Tether because it’s smaller, cheaper, and there is a gadget that can run 10Mbps Ethernet 1.5 miles over RG6 coax. See more here.

And that the way it goes. Invention and construction are best done as a community. Nothing worth doing is going to be easy. It’s going to fail many times, it’s going to take longer that expected, it’s not going to look like what you envisioned in your head, it’s going need to be attempted again and again. Community is not just about finding the best answers, it is there for support. So come out to our open house this Saturday 10 to 2. See what we are doing and consider joining our crew.

“Slovak robotic sailing boat was trying to cross the Atlantic” Meet Andrej Osusky from Lanzarote, Canary Islands who is designing and building an autonomous sailboat. That’s the kind! …and yes, he has great taste in T-Shirts.