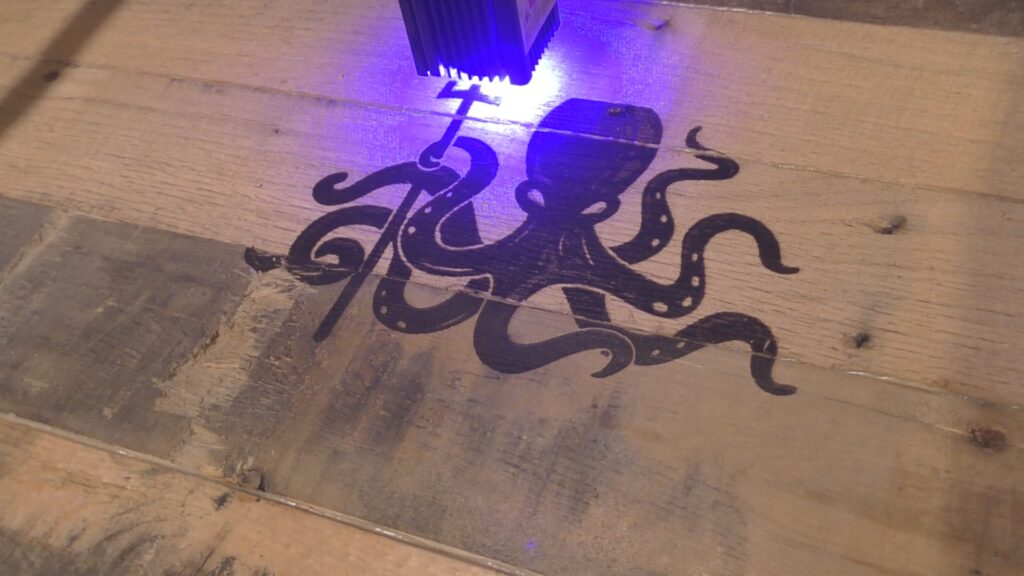

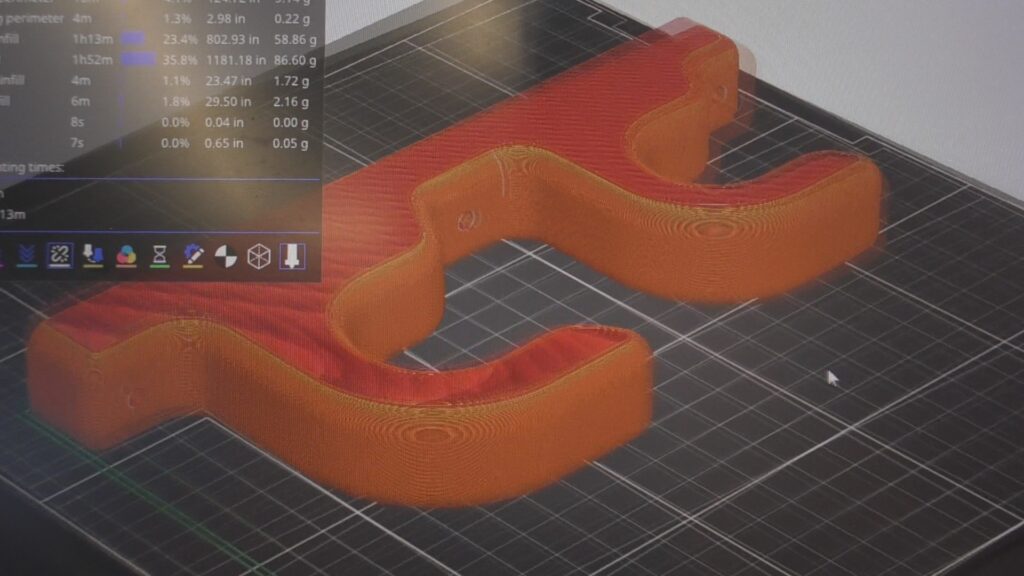

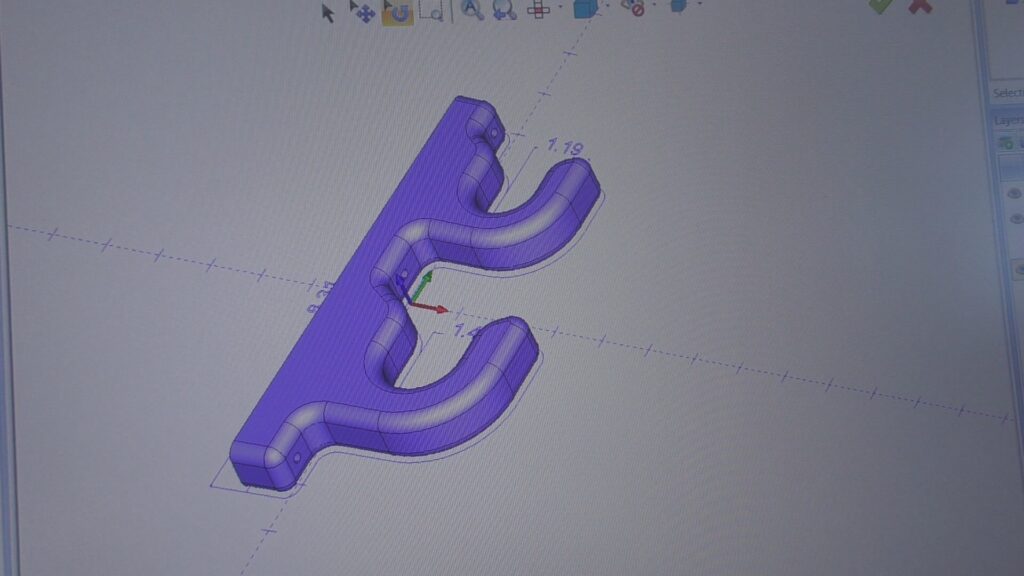

This 3D printer is far better than my previous 3D printer. They have come a long way baby.

Q1 Pro 3D Printer is On Sale Now for $469, save $130 before it goes back to $600.

Q1 Pro 3D Printer is On Sale Now for $469, save $130 before it goes back to $600.