Why Build a Boat?

Building a boat is the wrong thing to do if you want to start sailing and traveling. If that is what you want then go buy a used boat. There are lots of great deals out there. Building a boat is for people who want to build a boat that they can then use to sail and travel. For me, it’s learning new skills and preparing for new career. I want to explorer, hunt for wrecks, dive, salvage, and work with oceanographers, marine biologist and anthropologist. I actually think a 75 foot boat for a couple of people is ridiculous. I first decided what I wanted to do and then set about building a boat that could do those things. So if sailing from one bar to the next is your idea of fun, then 36 ft is more than enough. If charting to divers who are recovering sunken cargo is your thing, then you’ll need a bit more space and equipment. If you are not happy building, then DO NOT BUILD A BOAT. Buy a used boat and go sailing. To build and boat the building process must be part of your dream.

Money Money Money

You can easily quadruple that cost by adding all sorts of yachty crap. So decide how much crap you want. Building bigger does reduce the cost per square foot some, but not greatly. You can build a 36 foot origami boat in one year for $20,000 if you’re really cheap, and you will not need two cranes. I will have 400 to 500 thousand in the boat before it touches the water and we are building a work boat, not a yacht. So you don’t have 500,000 laying around? Neither do I, but building a boat does not happen over night so you have time. We simply downsized everything and devoted every dime to the boat. No vacations, fancy cars, expensive restaurants, bars, cloths, watches, jewelry, green fees, or 401K’s. I am focused on nothing other than the boat until I die or the boat is completed. So if money means a lot to you, DO NOT BUILD A BOAT! Just take the cruise ship.

And yes, with dedication and focus anybody can do this. Set our priorities and start. We were once a nation of people who crossed oceans, settled new lands, build great things, explored, and pursued our dreams. The adventure starts when you decide that the balance of your checking account has nothing to do with it.

Spring 2006

Once we decided to build a boat we set out to find a building site where we could live on site, have plenty of room, and where no one would care about the noise or scenery. and I would be close to my day job in downtown Tulsa.

We found was a 100 x 200 ft lot with an abandoned house beside the rail road, highway, tree service yard, steel yard, and scrap yard. In the heart of neighborhood notorious for the number of Meth Labs and other drugs. We doubled the sellers best offer and paid $1,500. No, that’s right. 1,500USD. Then we set about rebuilding it.

The really surprising thing? We love the neighborhood. Seriously! There are good people here. Hard working people that are struggling to make a better life the best they can amongst challenging circumstances. Much like the old west. They are harder, tougher, and they don’t wine about stupid shit like dust on their BMW. People often ask me what if my neighbors hate me building a huge boat in my front yard. The answer is no. They respect me. And I respect them. I think that it’s only when you get in a neighborhood with a high density of BMW’s an white collar snobs and you find the people willing to infringe on your freedoms. That group only respects conformity to their values.

August 2007

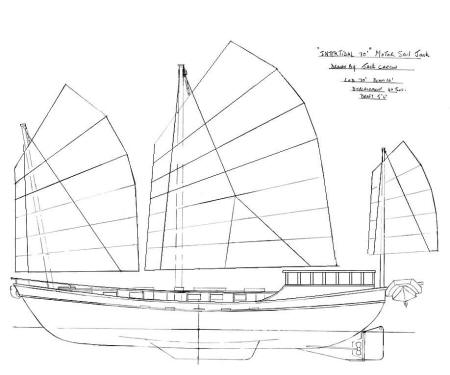

We visited Paul Liebenberg to see his 65ft origami steel, twin keel, junk design drawn up by Jack Carson who is also a local for part of the year. See “Paul’s Junk” for details and photos.

Paul’s boat is a perfect example of what Kay and I had been looking for. And Jack Carson and Monica live part of the year on Bella Via so they understood what we needed. Jack also proved to be flexible and open to discussing ideas. That’s unfortunately hard to find among most boat designers, and boat builders for that matter. There is a lot of entrenched thinking out there.

So our plans called for junk design with a cargo hull for a shop and a full pilot house. Jack’s job was to get the hull shape with the required space. No more that that. The interior of the hull would be divided into forward cabin, cargo hold, engine room, aft cabin and a big pilot house would ride on top.

Originally we were planning to build in 3/8 inch aluminum, but that switched to 1/4 inch steel. You can debate aluminum or steel for days, but the bottom line is that for a work boat, each have their good side. At Jacks suggestion we also dropped plans for a center lifting keel in exchange for twin bilge keels. The draft will be about 5 1/2 ft, but it is a simpler hull to build and and maintain.

To create our plans, Jack started with a piece of paper that had the 64ft hull drawn on it in 1″ to 1′ scale. He then made some changes, transferred the drawing to sign board, cut it out, folded it up, glued the seams, took measurements, ran some calculations, adjusted the original drawing and did it again. Three models latter he was done. No CAD, no CAM, no Computer, “very caveman” as he said.

You can read more about Jack and Monica in a Latitude38 article:www.latitude38.com/changes/Changes05-05.html

Vancouver Island is the Meca of origami boats and Jack is very failure with Brent Swain’s origami work.

July 2008

“the best-laid plans of mice and men often go awry”

As China’s economy boomed the price of steel steadily rose, so even though we did not plan on starting for at least 2 more years, we borrowed money and purchased steel at close to 61 cents a pound, right before the markets crashed.

Nov 2008 – Found a $500 school bus. The windows will be used in the pilothouse and the rest was sold for scrap with a little profit.

May 2009 – Standing in the rain with a cold and fever paid off as we were able to get our deck crane for $2,450

July 2011

Preparing the building pad. Now were starting to get serious. The obstacle tell now had been asubmarine, also named “Seeker”that we started building 10 years earlier. We finally got that sub into the water and I could easily see another two years of work to be done. So we sold it for cost and moved to the live-aboard sailboat dream that had cunningly replaced the submarine. Actually it started with visitor who wanted to talk welding. He planted the idea of building a sailboat and taking it down the river system. Then we drove along the Florida coast were we wanted to move with our submarine, and after setting in grid lock for hours, a boat started to look ideal.

“There’s no thrill in easy sailing when the skies are clear and blue, there’s no joy in merely doing things which any one can do. But there is some satisfaction that is mighty sweet to take, when you reach a destination that you never thought you’d make” – unknown

Aug 2011 – We found the foremast via Craigslist, outside of East St. Louis, Illinois. Only problem is it was actually 47 feet long and not the advertised 40 feet. The drive back was less than 50 mph making for a 23 hour long day. The up side is that the Suburban gets much better mileage at 50 mph.

Flipping again but this time with Budgit electric hoist and not the Harbor Freight manual chain hoist. …what a difference.

After four days for grinding, back gouging, and welding it starts to become a part of me. I feel the grinder’s vibration, the heat of the weld on the back of my hand, and smell the flux. The routine becomes a time to think and reflect. I ignore the pain in my muscles and the cold in my boots. I dream of blue water and white spray and exploration below the surface. Then I have to get up Monday morning, put on my sheep cloak and go back to the cubical farm. …well, at least I get to rest

So after bringing the Hundested controllable pitch propeller system 2000 miles home we opened it up and discovered that parts were missing. Sweet opportunity.

“The trouble with opportunity is that it always comes disguised as hard work.” — Anonymous

Taking a break from the Hundested, we took advantage of some nice weather to build sand blaster. For us, a wet sand blaster is the way we will go. No dust, no screening, no drying, no pissed off neighbors, and we can reuse the sand.