A fantastic improvement was the addition of a PID that held the temperature of the burnout kiln at 1000F plus or minus 20 degrees.

The PID triggers a Solid State Relay and the powers a solenoid valve that simply added more gas to the burner as needed.

With only one small crack in the mold we bought our 70 pounds of NiBrAl to pouring temperature.

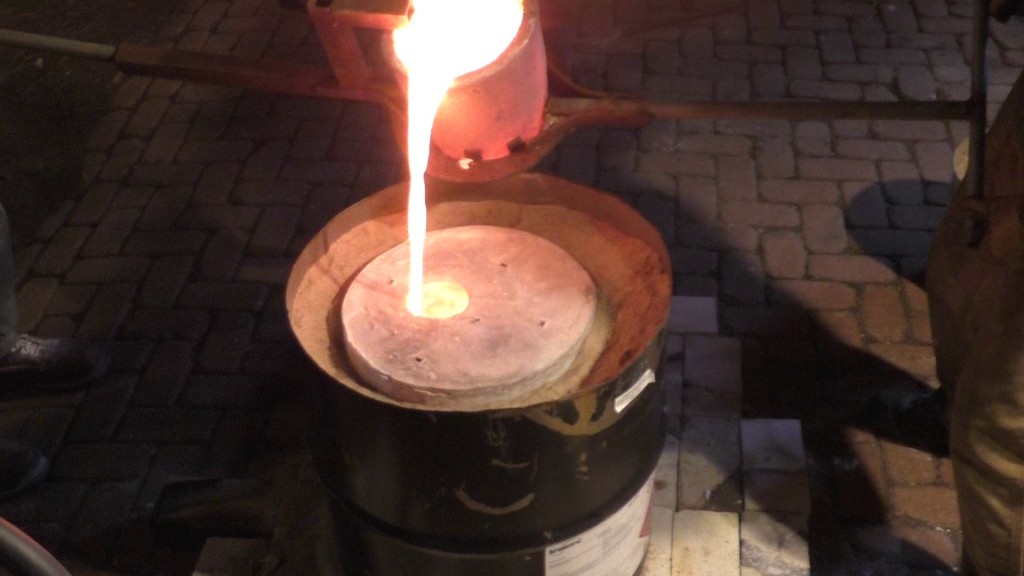

The kiln was removed. A metal barrel placed around the mold and sand added to keep any breaks in the mold from escaping.

There was almost no off gassing when the 2600F NiBrAl was poured into the mold, meaning that after 32 hours of burnout the wax was completely gone.

With the part so well insulated, the breakout will have to wait till tomorrow, but I’ll bet you that a usable part is inside.

Happier than a puppy with two peters. 🙂