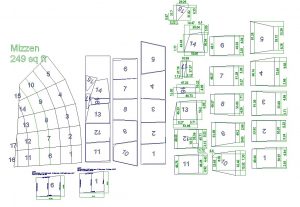

We learned while cutting the panels for the Mizzen sail; the really small one, that measuring and cutting the each panel correctly is very important and it takes a long time. We already have the shapes for each panel in CAD so wouldn’t it be dandy to cut them on the CNC Table. They are actually too big to cut in one go, so we’ll need to cut part of the panel along with some registration marks and then move it over and finish the cut. Routing is out, or we think it is. I’ve not seen anyone try to route cloth, even Sunbrella which is a heavy plastic cloth. Besides, the edges need to be burned so a hot knife like a soldering iron needs to be used. I have not seen that either, but I think it would work. Razor blade drag knifes are used but again that will not burn the edge and keep it from fraying. So how about a laser. Yes, it’s the stuff from child hood fantasies which means with have to compensate for the “you’re just doing it with a laser because it’s cool” syndrome. If we don’t compensate for that we end up owning something like a 3D printer before we have any clue how to use CAD which becomes apparent to our friends when we only print toys from Thingiverse. So what’s the scoop on these lasers? Will a Chinese 3 watt laser cut Sunbrella at a reasonable 20 inches per minute. Will it make it through 70 panels. Would be better off just letting the CNC Table mark the panels with a sharpie and cut them with our hot knife?

We learned while cutting the panels for the Mizzen sail; the really small one, that measuring and cutting the each panel correctly is very important and it takes a long time. We already have the shapes for each panel in CAD so wouldn’t it be dandy to cut them on the CNC Table. They are actually too big to cut in one go, so we’ll need to cut part of the panel along with some registration marks and then move it over and finish the cut. Routing is out, or we think it is. I’ve not seen anyone try to route cloth, even Sunbrella which is a heavy plastic cloth. Besides, the edges need to be burned so a hot knife like a soldering iron needs to be used. I have not seen that either, but I think it would work. Razor blade drag knifes are used but again that will not burn the edge and keep it from fraying. So how about a laser. Yes, it’s the stuff from child hood fantasies which means with have to compensate for the “you’re just doing it with a laser because it’s cool” syndrome. If we don’t compensate for that we end up owning something like a 3D printer before we have any clue how to use CAD which becomes apparent to our friends when we only print toys from Thingiverse. So what’s the scoop on these lasers? Will a Chinese 3 watt laser cut Sunbrella at a reasonable 20 inches per minute. Will it make it through 70 panels. Would be better off just letting the CNC Table mark the panels with a sharpie and cut them with our hot knife?

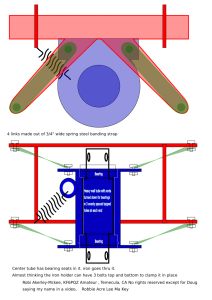

Robi Akerley-McKee, one of our viewers sent us a design for a “drag knife” attachment for the CNC Table that holds a pen style soldering iron that can be fitted with a blade.

Drag knife designs are available on Thingiverse. Maybe there is an idea there for incorporating a soldering iron with a knife blade tip into a 3D printed holder.