Diesel / Hybrid / Electric Drive

Why have one prop drive system, when you can have three? This is what happens when you watch fuel prices and wonder how your going to pay for that stuff.

The current plan is to remapping stage 1 to 2 and use a 150 to 200 hp diesel engine for full speed, an 25 kw (33 hp) 3 phase generator normally for shop power that can drive a 3 phase motor also connected to prop shaft and finally a 9 kw (12 hp) DC motor / generator that will be powered from the batteries and also recharge the batteries when under sail power.

Diesel Engine

Diesel Engine Tutorial

Growing up like most farm kids I worked my share of diesels in Case backhoes, Mercedes cars, International Harvester, and Ford tractors, but only replacing parts like starters, pumps and such. Until I got the Ford 7.3 for the submarine I had never messed with the fuel pump or glow plugs. You can read more about the Ford 7.3 here: Engine Tune Up. Gather more information on Effuel reviews about how you can manage your fuel usage and improve your vehicle’s performance.

Diesel engines have a longer lifespan and require less maintenance due to their sturdier design. Additionally, diesel fuel is often cheaper than gasoline, saving money in the long run. Diesel engines in the Toyota RAV4 provide better fuel economy and lower carbon dioxide emissions compared to gasoline engines. They also offer more torque for better acceleration and towing capabilities. Check this article written by Patrick Oziegbe to learn more about Toyota RAV 4 best years and models

Having deciding to build a sail and charter work boat, I knew it was time to improve my skills. I did not want to be like the Captain of 20 years that we took our sailing course with and who had to call home when the engine would not start.

There are likely lots of good community college night courses on diesel mechanics, but I don’t have the patience for spending my nights in a classroom, so I decided on a home study course and spent $3600 on truck with a 170 HP Caterpillar 3116 with 150,000 miles on it. It was the perfect comprehensive home diesel repair course. There was a chance that if we liked this engine it might be the engine we drop into the sailboat. At this point there that is not likely. While you can get after market rebuild kits for the 3116, they just don’t hold up like other engines. Which is one reason why you can buy a whole truck off a lot with one inside for $3600. You can read more about our experiences with the Cat 3116 here: Tow Truck.

Boat Engine Requirements

Paul’s boat is a 65 foot version of our boat and he is going to use a 50 Hp engine. That is small for the size of boat but right for Paul’s type of sailing. We on the other had plan to do charter work, salvage work and operate an ROV so we will sometimes need to get somewhere quickly and sometimes have the power to keep up out of trouble on a lee shore. For us 170 Hp was likely too low to start with and now that our boat has grown to 70 feet, Jack, our designer is recommending something in the neighborhood of 200 to 250 Hp.

Whatever the HP, make, and model, the overriding requirement is that we need to be able to perform a complete overhaul using remanufactured parts without the block leaving the hull. After that, the engine must be economical to operate and have parts widely available.

Engine Prospects

John Deere

Jack favors John Deere; www.deere.com, in part due to their use of sleeves for the cylinders that allow easy replacement if needed. The John Deere PowerTech 6068 Marine Engine or 6068SFM is a 6 cyl, 6.8 liter, turbo charged, electronic fuel injected engine available in 154 Hp for continuous duty.

6068SFM Performance Data – 6.8 liter M1 M2

Rated Power–hp (kW) 154 (115) 236 (176)

Rated Speed–rpm 2300 2400

Low Idle Speed–rpm 650 650

Peak Torque–lb-ft (N.m) 741 (1005) 674 (914)

Peak Torque Speed–rpm 1600 1800

Fuel Consumption – gal/hr for specified rpm

2400 N/A 9.2

2300 7.8 7.8

2200 6.7 6.8

2000 5.1 5.1

1800 (M2 Peek Torque) 3.7 3.8

1600 (M1 Peek Torque) 2.7 2.7

The same 6068SFM engine is for rated at various HP depending on how it will be used. The only things that change is the higher HP engines flow more fuel and have a higher turbo boost setting.

The bottom line is that using lower HP will give you longer life and greater duty cycle. M1 ratings are 24 hour a day and 3,000 hours per year and M2 are for 16 hours a day. They also have M3 through M5 which would be good for a full-time sailboat, but since Seeker is for part-time charter work, then getting to a destination on time will sometimes be necessary.

The John Deere tractor series also uses the 6.8 liter engines. The 7430 is rate at 165 hp. The intercoolers are air to air on tractors but most everything else should be the same. So there is a possibility of picking up a engine out of a tractor.

Other Potential John Deere Engines

4045 – 95 hp

3029T – 45 to 72 hp

4039D – 71 hp (Rebuild kit is $720)

On a 60kw generator with 3500 hrs it cost $7,250 (ebay 2009)

2000+ hrs engine only, wo/radiatior or muffler cost $1500 (craigslist 2009)

4024T – 43 hp

On a Sullair 185 cfm compressor with 5600 hr is $3850 (craigslist 2009)

On a Sullair 185 cfm compressor with 2600 hr is $2450 (Enlow Auction 2009)

John Deere 20 KW with and sits on 150 gallon double wall tank Stamford newage end with PMG, 500 hours $7,000 connect single or three phase.

Cummings

The following Cummings models are in the correct power range:

Model HP RPM Peek

Touque GPH

@ Peek Fuel System Duty Cycle

QSB5.9-230 HD 225 2600 1600 3.1 Turbo Charged Heavy Duty

6CTA8.3-M 255 1800 1200 4.2 Turbo Charged Continuous

QSL9 – 285 CON 285 1800 1400 6.9 Turbo Charged Continuous

The Cummins C-Series has replaceable cylinder sleeves and 97 and older models use a very reliable mechanical injector according to a trusted diesel mechanic. The B-Series for 97 and older also have the mechanical injectors but not the replaceable wet sleeves. However even if you have the wet sleeves it may still be necessary to have the block pulled so the top of the block can be machined. This can be done “in-frame” when the engine is in a truck, but not necessarily in a boat.

The Cummins 6C8.3-210 is 210 hp, with a maximum of 2400 rpm and peek torque of 446 lb-ft (605 Nm) at 1300 rpm. It was originally introduced in the late 1980s and co-designed with the Case Corporation. It uses a very reliable mechanical injection, piston style fuel pump often called a “P-pump”.

We almost purchased the bus in the video, but we did something smart. This engine had sat for years, so we made the sale contingent on the bus making the 200 mile trip from Kansas to Tulsa. It make it 100 miles before it blew up. The coolant system was not working and it lost one cylinder at least. So glad it was not me with a broken down bus on a Kansas roadway.

Electric Drives

Need to Know

Watts = Amps * Volts {can also be written Power= current x voltage}

Amps = Watts / Volts

Volts = Watts / Amps

Watt-Hours = Volts * Amp-Hours {or energy = voltage x current x time}

Batteries in series = add voltages

Batteries in parallel = add amp-hours

Motors in series = divide voltage by # of motors

Motors in parallel = divide amps by # of motors

Power is measured in metric units as watts (W) or more commonly kilowatts (1kW=1000W) or horsepower in the imperial units (1hp = 746W).

Power (kW) = Torque (Nm) x RPM / 9549

Power (hp) = Torque (lb/ft) x RPM / 5252

Energy is what gives an electric car/boat range. It is the product of power or kW and time (E = P x t) or the product of voltage and amp-hours. Kilowatt-Hours (kWh) stored in a battery is the measurement of total electrical energy. For example a 12v, 55 amp hour battery at the 20 hour rate will provide; 12v x 55amp/hr = 660 watt-hours. To power a 19.2 kW motor, we would need; 19,200 / 660 = 29 batteries. But we can actually only about 10 actual before we have drained them to 55 or 60% which is their recommended depth of discharge.

Higher voltages = Higher motor RPM and higher top speed if we were powering a car, but powering a 40 ton boat to it’s hull speed is not the goal and that propeller is sized for lots of torque and only about 600 rpm so we will be gearing the motor down even with lower voltages. Higher voltages are often more efficient, and if we had 120v DC, then many of the shop tools could be powered directly from the battery, so it’s worth keeping in mind.

Power Requirements

Power Recommendation from Emotion Hybrids site electricmarinepropulsion.org :

Emotion Hybrids site electricmarinepropulsion.org

Power output

Torque

Voltage

Max, current draw

Weight

Length

Width

Max. prop diameter*

Max. displacement

Max. monohull length** 16 kw

120 lb-ft (160 N-m)

144 vdc

111 amps

130 lb (59 kg)

19 in (483 mm)

11 in (279 mm)

25 in (635 mm)

26 t (23.6 mt)

50 ft (15.2 m)

Emotion Hybrids recommends a 120 lb-ft motor for 26 tons, so Seeker with 40 tons would need about 200 lb-ft torque. Compare that to a John Deer 6068 with 741 lb-ft at 1800 rpm and it’s easy to see that it’s certainly less power. The 6068 will loose a lot of torque to the transmission but I doubt it comes anywhere near 541 lb-ft.

If we decided that 300 lb/ft is sufficient then we can get that from a 100HP DC motor. A 100HP Motor at 1750 rpm = 300 lb/ft torque:

T = HP x 5252 / rpm = 100 x 5252 / 1750 = 300 lb/ft

Bigger DC Motors do exist: Horsepower 100, RPM 1750/2000, Weight 1118 lbs, Cost $13,777. Plus; Variable Speed DC Motor Drive, Input 230VAC Three Phase, Output 240VDC Armature, 100 HP, 330 Amps Cost $4,952. That is 330 a x 230 v = 75.9 kw and is in line with the 115 kw from a John Deer 6068 M1.

www.driveswarehouse.com The cost is considerable because this is just the motor and not the generator/s. Used units with controllers are available for 25% of the new cost but these motors are not specifically designed for regenerative prop drive so they are not going to be as efficient or practical. A 35kw, 3 phase Onan diesel generator used will cost around $7000. The up side of this approach is that the boat’s shop will need lots of electric power and so having a big generator would be nice.

Ton Displacement / Kilo Watt

Vendor

Model

Kilowatts

HP

Maximum Recommended

Displacement in tons Claimed Diesel Equivalent in HP Ratio

Tons/Kw

www.solidnav.com Explorer 4 5.3 6 24 1.5

electricmarinepropulsion.org E motion 16 21.5 26 1.6

www.asmomarine.com 17 22.8 52 to 60

Based on these vendors standards, Seeker at 40 ton would need a 27 kw motor and unloaded at 20 tons would need 13 kw. Because we only intend the motor for slow speed then perhaps 10kw will suffice. Besides motor will need to be adjusted according to the cost and size of the battery as well as the ability for us to recharge it using solar, wind, and prop.

DC Motors

Thoosa 17000 from Asmo Marine, www.asmomarine.com and also www.ngcmarine.com is a 96V, 200 amp, 17kW said to replace a 52HP-60HP engine. These use a cog belt reduction to the drive shaft. The motor works as a generator and charges the battery bank, while the boat is driven by sails or engine in excess of the motor’s throttle speed.

Advanced DC #L91-4003 72-120 volt, reversible motor from www.evparts.com

Current Ratings: 130 amps continuous, 150 amps for one hour, 500 amps peak

Horsepower Ratings: At 96 VDC, 13.6 HP continuous, 15 HP for one hour, 26.4 for 5 min., 62 HP peak

At 120 VDC, 16 HP continuous, 17.9 HP for one hour, 31 HP for five min., 72 HP peak

One Hour KW rating: 11.4KW @ 96VDC, 13.5KW @ 120VDC

Weight: 85 pounds

Others: http://www.hydrogenappliances.com/manta.html

A good idea from Richard Clifford-Smith: How well the permanent magnet motors work as generators depends on how fast the prop can spin them when you are under sail. If that was a problem they could perhaps be connected in parallel for driving the prop but series for charging when sailing. Failing that it is possible to convert dc voltages both up and down using electronics.

AC Motors

Most big industrial motors are AC. And 3 phase AC motors are sometimes used on eclectic vehicles, especially the larger EV’s like buses. They lack the same high torque at low rpm as the DC motors but they are slightly more efficient. A 3 phase AC motor will require a revising motor starter with an overload relay. Even better would be a variable frequency speed controller. When using the AC motor to maneuver it will be necessary to repeatedly turn it on and off and possibly reverse the direction. If a smaller DC motor is available this job could be left to it, but if the AC motor is doing the work then it starting surge would quickly over heat it. Using a frequency speed controller would allow it to run a slow speeds instead of being turn off, and when the direction is reversed it would ramp the speed down, reverse the motor and ramp the speed back up.

Batteries

Just for a starting point, we’ll work with a 48 volt forklift motor running at 10 kw or 208 amps. If we want to run this motor at this power for 6 hours, then we will consume; 10 kw x 6 hrs = 60 kWh (kilowatt hours). The useable amp hour storage for the battery is; 60 kWh / 48 v = 1250 amp hours. The usable amp hours supplied by a battery are 1/2 the advertised amp hours if the battery allows a 50% depth of discharge. So in reality to get 1250 amp hours from batteries with a maximum recommended depth of discharge (DOD) of 50% we nee two 1250 amp hour batteries or a total of 120 kWh.

For example Solar One has batteries with a DOD or 80%, but only taking them down to 50% will guarantee a longer life. However their 1270 amp hour batteries are $12,620 each. $26,000 for two batteries. Wow! That’s the price of a new 200 HP marine engine. These batteries should be able to provided 1250 amp hours 2500 times before they need to be replaced. So that is 2500 x 6 hrs = 15,000 hours of electric motoring. My guess is that if you got 15,000 hour out of a marine diesel that you would feel good about it. However a 10 kw (13 HP) diesel is only going to cost about $2000 but it drinks about .4 gallons per hour. That comes to 15,000 hours x .4 gph = 6000 gallons of fuel. At lets say $4.5 per gallon, that is 4.5 x 6000 = $27,000 of fuel. I doubt many $2000 diesels will live 15,000 hours either, but we still have the cost of solar panels and wind and prop chargers to put 60 kWh back into the batteries.

6 – 1000 kw solar panels provide 6 kw for 6 hours a day = 36 kWh. They also cost about $1000 each. With losses, we will need 2 days of sitting in the sun for every 6 hours of electric motoring.

An amp hour (AH) is a rating usually found on deep cycle batteries. If a battery is rated at 100 amp hours it should deliver 5 amps for 20 hours, 20 amps for 5 hours, etc.

With a 200 amp draw at full power, it would be best to have a battery bank that would provide 200 amps per hour at 96 volts over 20 hours and only discharge the batteries to 50% which is the maximum “depth of discharge” recommended for lead acid batteries and well above the 80% DOD allowed for some deep cycle batteries. Allowing for a constant 200 amp load without damaging the battery bank. A typical 12 volt, AGM, is 55 amp hour, so 4 of then would provide 220 amp hours at 12 volt, and 8 times 12 makes the required 96 volts, so that comes to 32 batteries. At $165 each that comes to just under $5280 for the batteries.

A commercially-available deep-cycle battery storing a nominal 1.2 kWh costs approximately $70 US at retail. The AGM’s listed above are 12v x 55 amp hour = 660 watt-hours or about $330 for 1.2 kWh.

In kWh or kilowatt hours, the same 200 amp motor at 96 volts is using 19.2 kilowatts ( 200 x 96 = 19,200 ). 19.2 kW * 1 hours of run time = 19.2 kWh. 19.2 kWh / 660 Watt-Hr per 1 AGM = 29 Batteries for 1 Hour

The upside to a lot of batteries is that they can be hooked up to a rectifier in order to supply AC power to the shop tools, and it provides a large capacity for storing power generated by solar panels, prop and wind. At 43 pounds each it is also 1000 pounds of ballast. They are 10 1/2″ x 7 3/8″ x 8 3/4″ so it would be easy to put all of then in the top of one of the keels. Having 96 volt DC available also makes it possible to run some of the tools directly from a 96 volt DC motor.

Off-grid homes that uses there batteries for large house loads are a better model for how we plan to use our batteries than are most marine power applications. With that in mind Trojan: www.trojan-battery.com, T-105s or L16s are popular choices that provide over 1500 cycles to 35 percent discharged. However HUP Solar One batteries; www.hupsolarone.com, manufactured by General Battery, are considerably more robust. These are warranted to endure 2,100 cycles of 80-percent discharge, or 4,000 cycles of 50-percent discharge. These are also massive batteries that will require a crane to move.

An off-grid formula from Solar One is: (Daily Power Consumption kWh) X (Days of Autonomy) X (1.2 80%DOD) x (1.3 System Losses) = Battery capacity. Our 10 kW Motor x 12 hours x 1.2 x 1.3 = 187 Usable kWh. This would require 3 – Solar One, SO-6-85-33, 48v 64.8 kWh at 20 hour rate batteries which are 5344/lb each for a total of 8 tons. But the real problem is that the total cost is $15,600 for a total cost of $46,800. So we need a smaller motor or a shorter run time because $15,600 is about the limit of our budget.

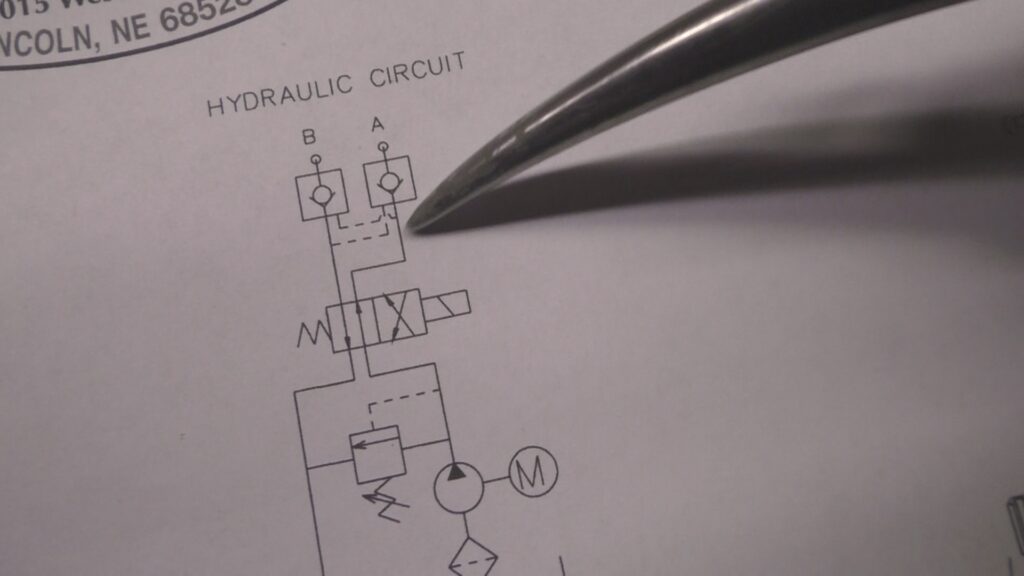

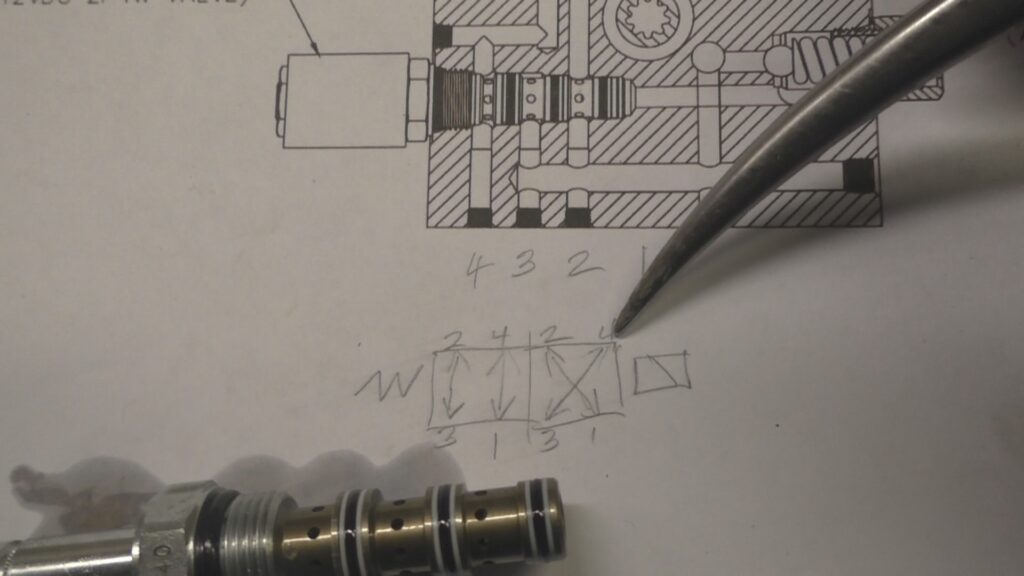

Many thanks the Andy McDonald on loan from the USAF. We got the crane back together and learned a lot about hydraulics along the way.