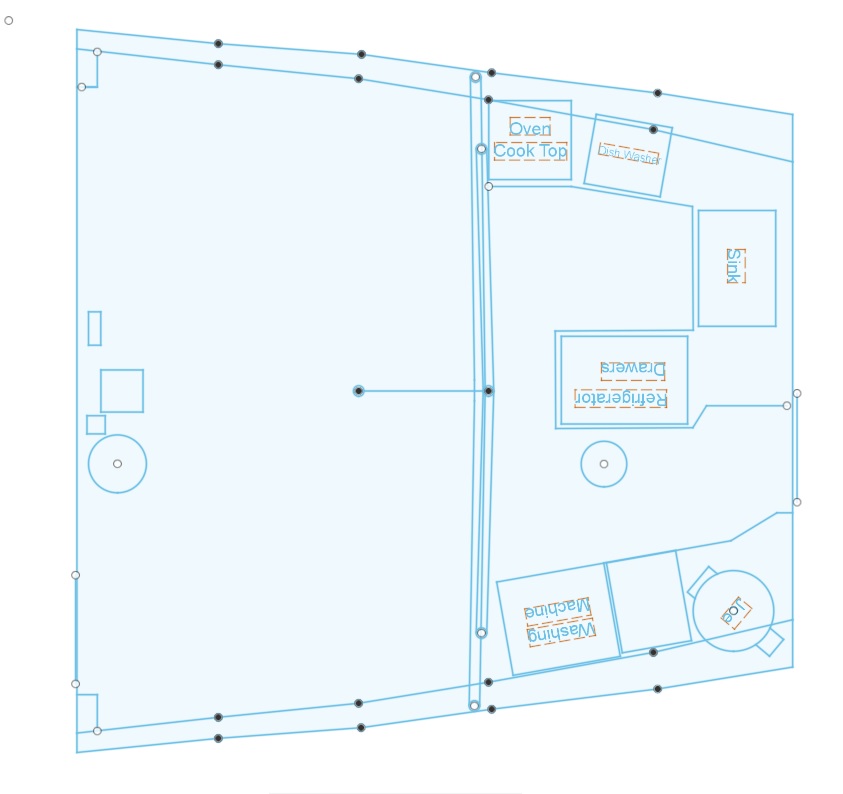

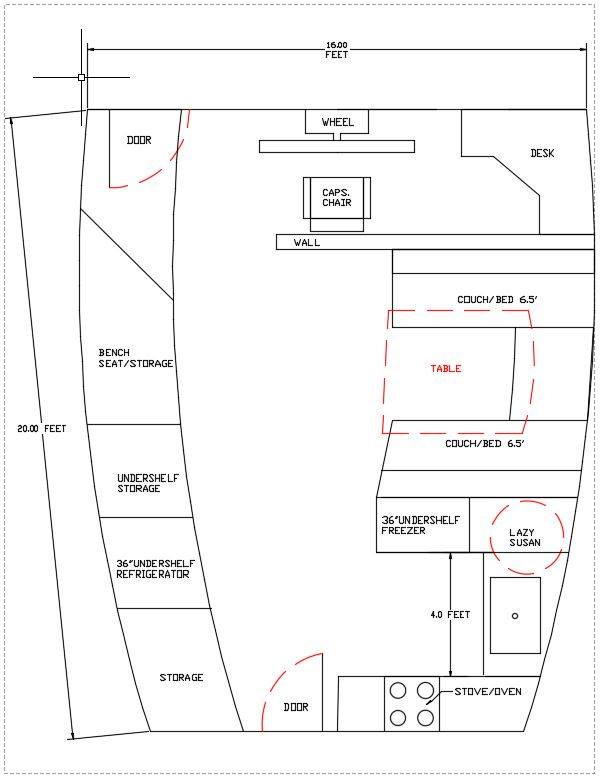

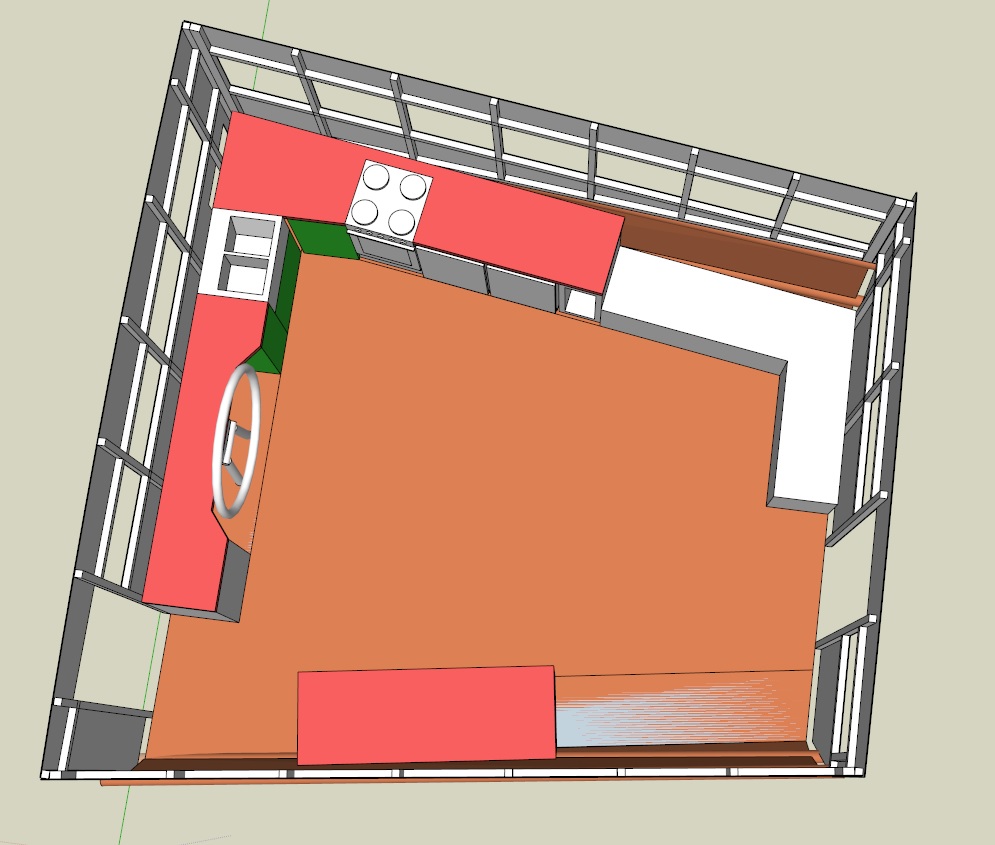

Many many thanks to Monica and Charlie for giving us a starting point for the layout of the pilot house. Frankly and this point I don’t see anything I don’t like. Open, roomy, sleeping for two. Maybe an island with some galley storage and a seat for the helm, but the more I look at it more I like it without the island.

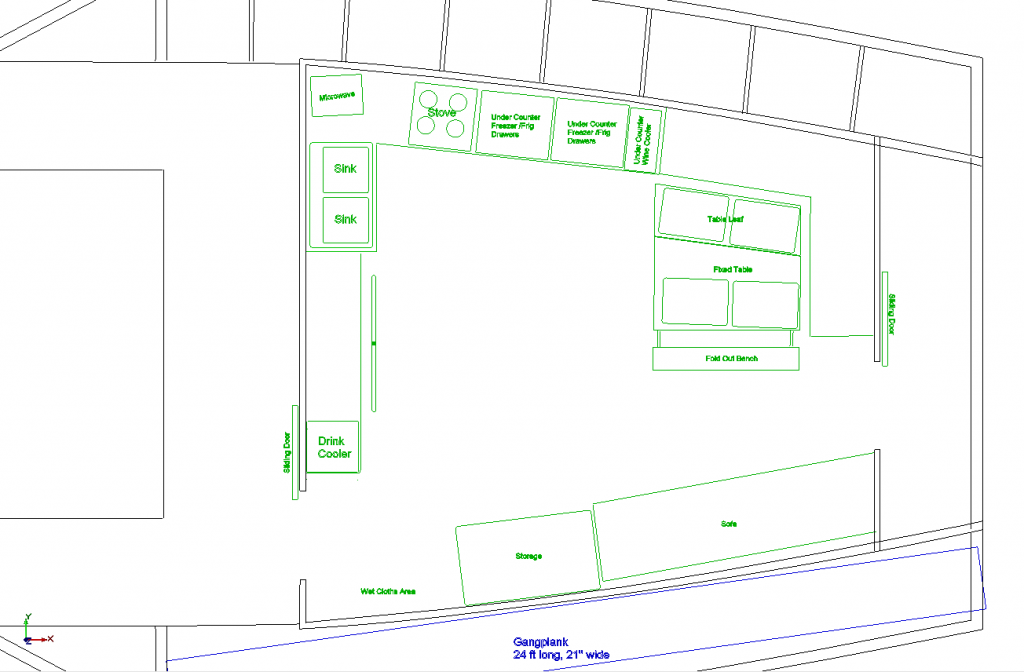

And what we finally decided to do

Here is how I see it working.

HELM

The helm is dead center and the bench in front of the helm is for a computer or too. The computer is the primary navigation setup. Radar will likely be there too, or mounted above the windows. There is no traditional navigation table or chart table. If we have a paper chat then it gets spread out on the table while a route is being laid out and the folded up and placed by the computer. Betsy has a chair picked out to go behind the wheel. Immediately below the wheel and just off the the port (left) there will be a port hole mounted into the floor. This will give a view into the engine room. A light mounted in the bilge will allow the bilge to be easily inspected from the pilot house. The port hole will also allow for handing tool and such to and from the engine room and pilot house.

EMERGENCY HATCH

Some where in the floor in the aft half of the pilot house will be a hatch. Likely just another 24 inch port hole. This will provide natural light and ventilation to the aft cabin and also serve as an emergency escape from the aft cabin should it not be possible to exit through the engine room.

HAND HOLDS

Aluminum pipe hand holds will be attached to the ceiling and extend between the two door and branch off to the galley.

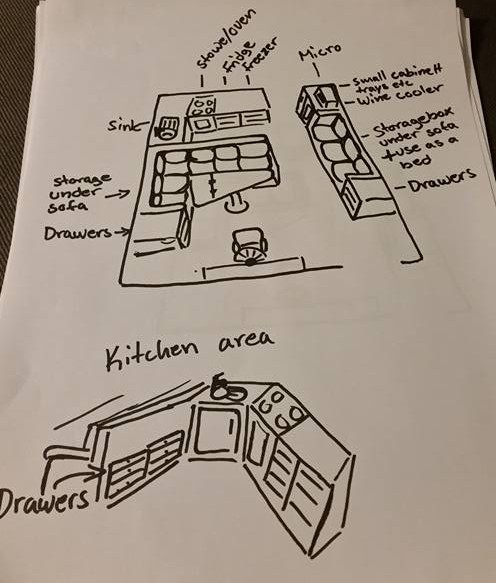

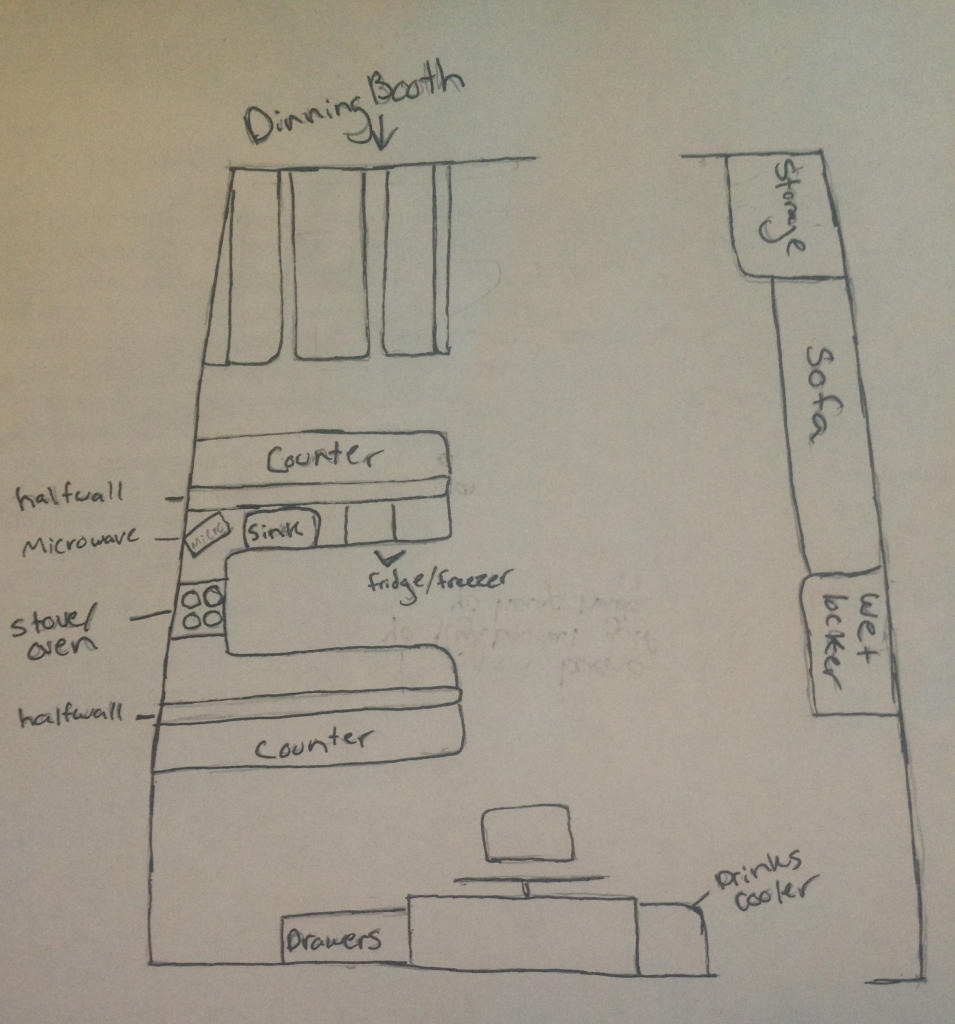

GALLEY

The galley sinks are frequently where items are temporarily stored and there location next to the helm give the pilot easy access. provide the cook an eyes forward view. A drip dry rack is built in above the sinks and above the window height.

MICROWAVE

A small counter top unit mounted in the corner. The cabinet space under that corner will house two propane tanks and be accessed through a door that opens to the deck. And gas leak will drain through the deck drain and over the side.

TRASH

Under one of the sinks.

STOVE

Four burner propane with an oven and mounted in a gimbal.

REFRIGERATOR FREEZERS

Two units both with two drawers each. The drawers can each be configured a refrigerator or freezer. The capacity can be scaled to accommodate the number of passengers. A small wine cooler.

TABLE

The table has an L shaped bench that will double as a single bunk. Storage is provided under the seat and behind the back. And the table has a leaf on the starboard (right) side that can slid back under there rest of the table in order to make it easier to access the bench as bed. The port side of the table has a bench that folds under the table that can accommodate two more crew.

SOFA

Provides seating and a second sleeping location. It can also be additional seating for meals with the addition of a simple to erect and remove table surface. Storage is provided under the seat and behind the back.

STORAGE

There is little easily accessed storage and little space above the windows so this storage area is the primary storage area for the galley.

WET AREA

The area just inside the forward door is where wet cloths can be hung to drip dry.

BEVERAGE COOLER

A beverage cooler is located just inside the forward door and under the navigation bench. This allows easy access to beverages for the crew without the need to access the galley.