Hydraulics

Hydraulic Equipment List

The anchor winch uses the most fluid and will not operate simultaneously with any other motor. The recommendation for 12 gpm only 3/8", but as there are several fittings and the length between the pump and motor will be about 100 feet, we will use 1/2" for the supply and 1" for the return.

Main Engine Hydraulic Pump The 200HP Cummins 5.9 main engine will power a Northern Tool; High Pressure Hydraulic Clutch Pump, 2.32Cu In, Maximum pressure 3000. 1 1/4in. NPTF inlet, 1in. NPTF outlet. 29.1 @ 3000 and 11.6 GPM @ 1200 RPM, about $520 Secondary Hydraulic Power Packs We want a secondary diesel engine power pump for backup and to save on the expense of running the main engine just to use the anchor winch or deck crane. For secondary systems we want a diesel engine powered unit that can also by used as a portable system for operating tools. As well as a 12v DC power pack that can utilize the boat's batteries at any time. 12v DC Power Pack ??????

The following formula calculates the HP of a pump: ( Pressure * Gallons per Minute ) / 1719 = Pump Horse Power So to reach our Northern Tool clutch pump's maximum 11.6gpm at 3000 psi we need: (3000 * 11.6) / 1719 = 20.24 HP. But the deck crane only needs 6 GPM at 2,350 PSI so if there were no losses then (2350 * 6) / 1719 = 8.2 HP would be sufficient. So if the winch can operate satisfactorily with 6 GPM at 2,350 PSI then counting for some efficiency losses, a 10 HP engine is needed.

So we purchased a 10hp Chinese diesel engine off eBay for $580. Another option will be a 13.4hp, water cooled Yanmar; www.surpluscenter.com has them for $1000. Or we may add a clutch and belt drive it from a diesel generator. But our 10hp, 418 cc, Chinese diesel is a 4 stroke and 10 HP at 3600 RPM. And 8.6 HP at 3000 RPM. It has a 1" shaft with a 1/4" key. The shaft turns counter-clockwise, like most small engines. If we direct drive a pump then the pump needs to work in the clockwise direction. Our clutch pump has a 2 groove, 7in. pulley that uses type A 1/2in. belts and rotates clockwise, so it will need to be mounted across from the engine. We'll plan on running the engine at 8.6hp or 3000 RPM but that's too fast for the pump. If we reduce the pump RPM to 1200 by using a 3" pulley on the engine to the pumps 7" pulley then the pump would spin at 1285 RPM (3000 * (3/7) = 1285) At 1200 rpm the pump can do 11.6gpm and 8.6hp then the max pressure we can expect from the pump is: 1247 psi. Horse Power / Gallons per Minute * 1719 = Pressure Anchor Winch The anchor winch is a converted truck winch powered from a PTO, or power take off and the truck's transmission. The PTO can switch directions and speed is relative to engine RPM. A normal PTO spins at 540 RPM so that will be the starting point for selecting a hydraulic motor. The worm gear came with a 1" pitch or size 80 roller chain sprocket on it that connected to to the PTO, but direct driving the worm gear will be better for our purpose so that there is no moving chain on deck to grab a loose line or finger. So now we need a motor for the winch that can use 11.6 gpm @ 1,247psi if we are powering it from the 10hp engine and 29.1 @ 3000psi if we are powering the pump from the main engine We want the winch line speed to be about 50 ft per minute on the first wraps, and it can be upwards to 350 ft/min on the final wraps. The smaller 6" wide side of our winch has the most change from the first wraps to the last. The calculation is (3.14pi *8.75 drum diameter) / 12in = 2.8 ft/revolution. 50 ft requires 50/2.8=17.8 revolutions. The worm gear reduction on the winch is 29:1, so 18 revolutions of the drum requires 18 * 29 = 522 revolutions on the motor. So we want a motor that does around 522 rpm with 11.6gpm. So when running it with the main engine it will be capable of much higher speed. Hydraulic motors are categorized by their displacement. For example an 8 cubic inch displacement motor uses 8 cubic inches of fluid per revolution. So: Gallons per minute * 231 cubic inches per gallon / motor displacement cubic inches = motor rpm. At 11.6 gpm an 8 cubic in motor is: 11.6 * 231 / 8 = 334 rpm. And at 29.1 gmp it's 29.1 * 231 / 8 = 840 rpm So if we want 522 rpm with 11.6 gpm then: (Gallons per minute * 231 cubic inches per gallon ) /motor rpm = displacement. Or (11.6 * 231) / 522 = 5.13 cubic inches. If we flowed 29.1 gpm to the motor it would spin at 29.1 * 231 / 5 = 1344 rpm which is way above the maximum rpm for most 5 cubic inch motors which is around 900 rpm. So we are going to need to limit the main engines rpm regulate the flow to the motor.

The motor we purchased is 5.9 cubic inch displacement so with the 11.6gpm the line speed should be: ((pump gpm * 231 / cu in displacement) / gear reduction) * ft per rotation = line ft per minute. Or (((11.6*231)/5.9)/29)*2.8=43.8 ft/minute The motor's 1" round shaft will direct drive the 1.25" square shaft on the winch's worm gear.

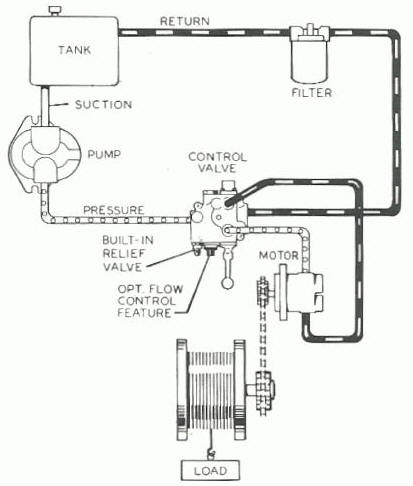

Hydraulic Motor Control ValveThe valve to control the winch motor will be mounted on the winch and have a control arm that makes it accessible from either side of the winch so that it can be easily access while working with either capstan.

The valve we selected is more than twice the cost of most single spool valves, but that's because it comes with a flow control adjustment as well as a relief valve. The flow control will allow us to limit the speed of the motor so that it does not exceed it's maximum 670 rpm when the hydraulic pump is being powered from the main engine. Addition flow will simply be router past the valve so it will allow us to control the maximum rpm of the spool when the hydraulic pump is being powered by the main engine and capable of too much flow.

Deck Crane

The pump should supply a minimum of 6 GPM at 2,350 PSI Northern Tool: High Pressure Hydraulic Clutch Pump, 2.32Cu In, Maximum pressure 3000. 1 1/4in. NPTF inlet, 1in. NPTF outlet. 11.6 GPM @ 1200 RPM, about $520

Bow Thruster 7kW, tunnel diam:9.8", thrust: 300lbs

|

5.9

cu in

5.9

cu in