There are really just two ways you can design junk sails (or chinese lug sails if you prefer that definition).

One is the old way, and that is thousands of years old. It’s whatever you have for a sailcloth with some battens of bamboo or like materials. It’s often called the “Eastern” way as in the Far East.

The second way is the “Western” way, or rather using technology to build the better mousetrap. Do you add camber (shaping) to the sails? How about airfoil like battens.

If you’re trying to win a race or pleasure sailing on inland waters, being able to head up to the wind as much as possible could be helpful and camber and specially hinged/shaped battens might give you the boost over the competition.

We figure thousands of years of success in a vessel that can handle just about anything dished out at it and doesn’t take a crew of a dozen to hoist the sails is the way to go.

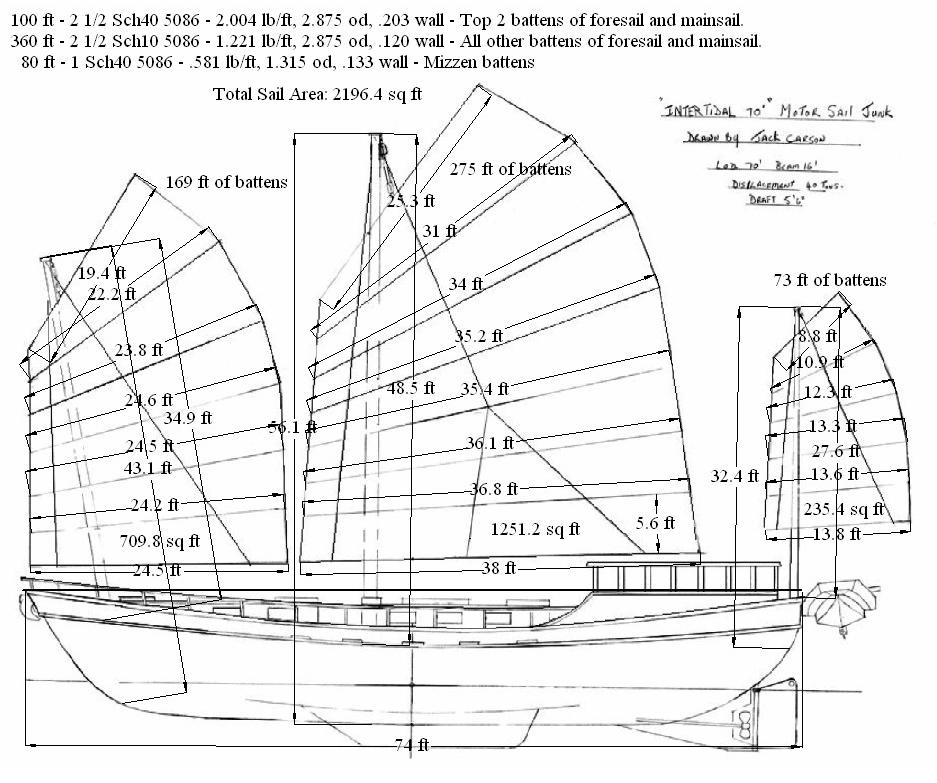

There’s a few books to help choose the design that suits you. We have a basic design by Jack Carson, who designed SV Seeker, although we might tweak them here or there to make them fit out purpose.

Books You Might Like

Sailmaking by Thomas Colvin Sadly, Mr. Colvin died a few years ago and the publishing of his book went with him. The contact information on this webpage won’t do you any good. You have to find somebody with a copy and then beg to borrow the book.

Practical Junk Rig by H.G. Hasler. Another must read if you plan to take on sailmaking. You need this book and the next one in order to figure out what Colvin is talking about as he wasn’t much on pictures and we’re not much on reading.

Sailmaker’s Apprenctice by Emiliano Marino This book brings it all together and includes details on how to actually construct the sail and what materials will be needed. A must have for our library.

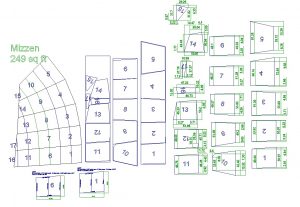

Start Small: The Mizzen

At 250 sq ft, our mizzen sail, or the one in the rear, is by far the smallest. And it is pieced together from sections cut from 62 inch wide Top Gun from SailRite.

At 250 sq ft, our mizzen sail, or the one in the rear, is by far the smallest. And it is pieced together from sections cut from 62 inch wide Top Gun from SailRite.

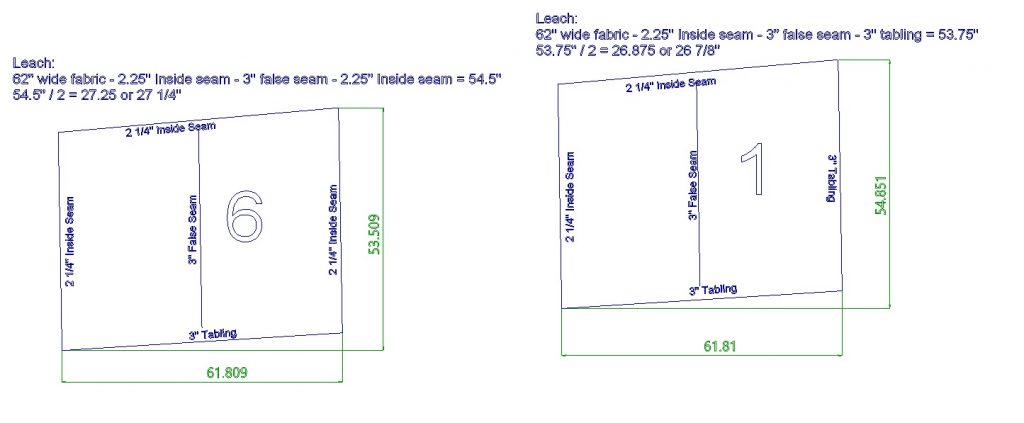

Step 1: We figured out that each 62 inch wide section would have a false seam in the center that was parallel to the leach or rear of the sail. That took up 3 inches of cloth. It would then be seamed to the sections it touched and that required 2.25 inches and were it did not touch another section we added 3 inches for the edges. So the sections along the leach are 53.75 inches wide and the sections in the middle are 54.5 inches

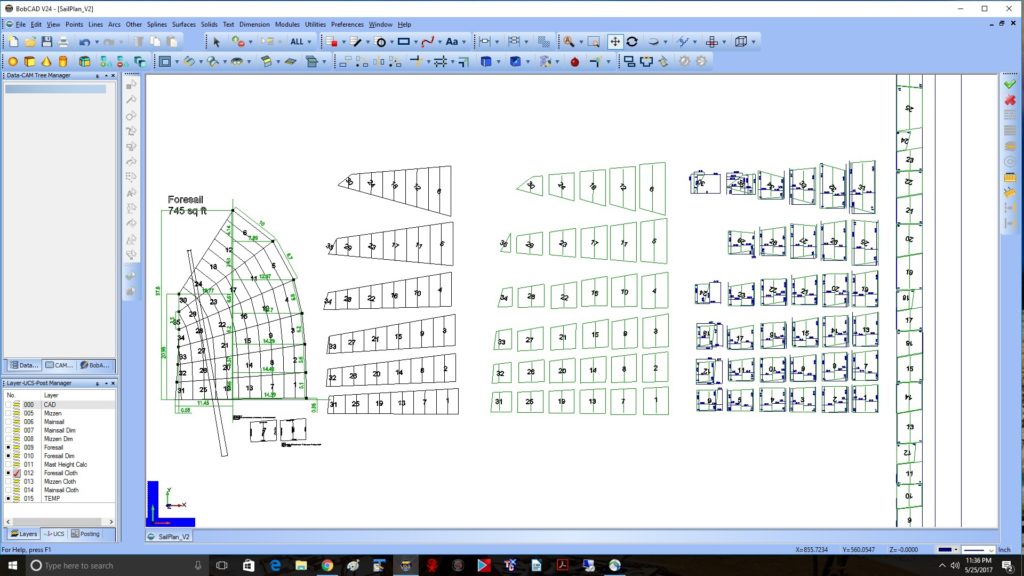

Step 2: With the actual wide of a sections were divided the sail area up, starting at the leach or rear of the sail and moving toward the luff, or front. That gave us 17 separate sections to be pieced together.

Step 3: We take each section and expand it out to the size it needs to be when it is cut from the roll of Top Gun, and arrange these sections so the fit onto the roll of fabric with little waste.

Step 4: Each section is copied out and dimensions are added to make it easier to lay out on the fabric for cutting.

And cutting is something we would like make easier. If our CNC Table was just 12 inches wider we could cut these panels without having to shift and register the cloth, and if we were going to do this for a living, we would absolutely automate it. Here are the ideas for automation: Laser?